In today’s rapidly evolving industrial landscape, staying ahead of the curve is essential. As part of our commitment to providing cutting-edge solutions, we are excited to announce our adoption of an advanced 3D industry software leveraging virtual reality (VR) technology.

This significant step forward will allow us to offer our customers even more precise, efficient, and innovative services, tailored to their unique needs.

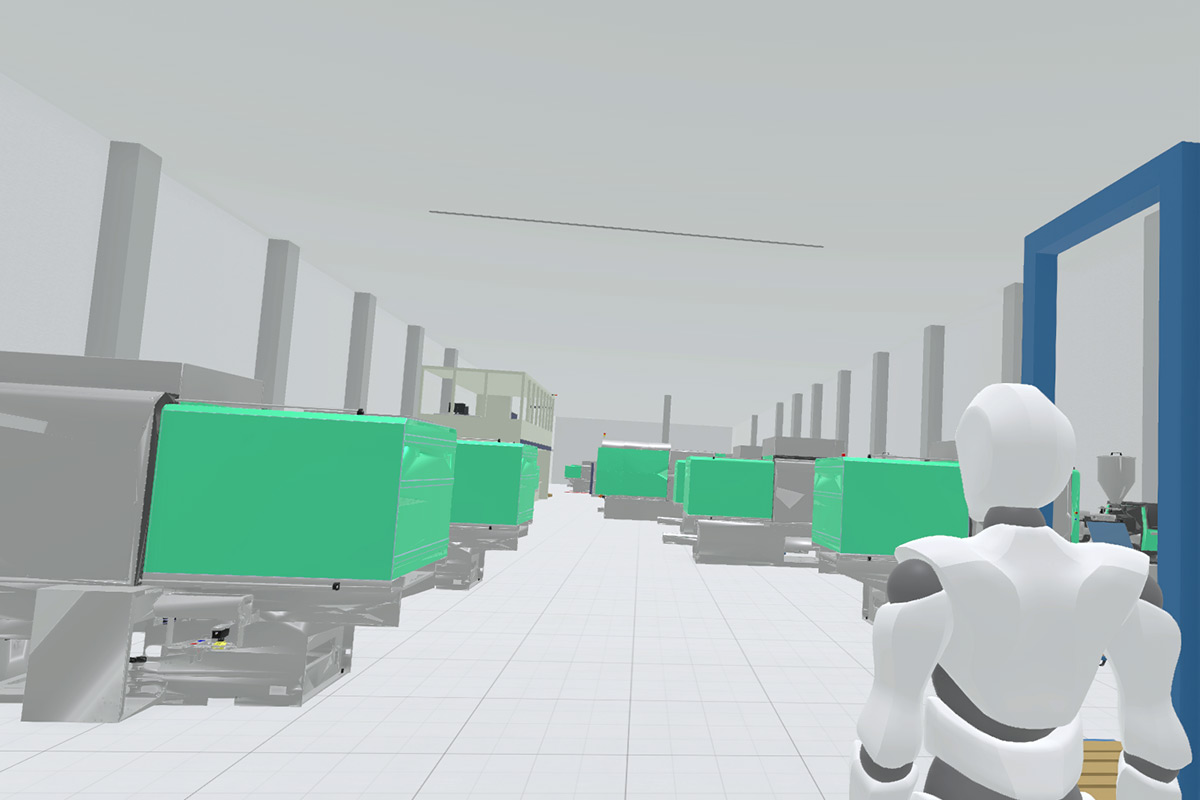

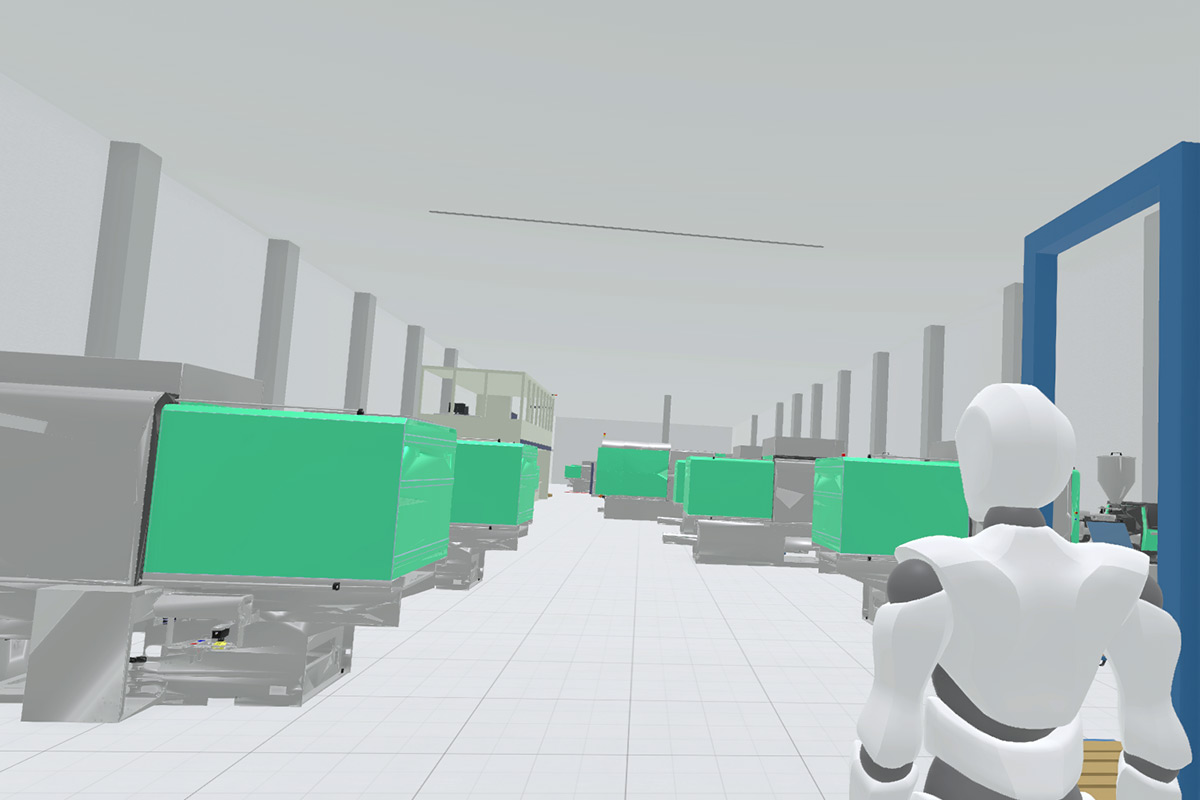

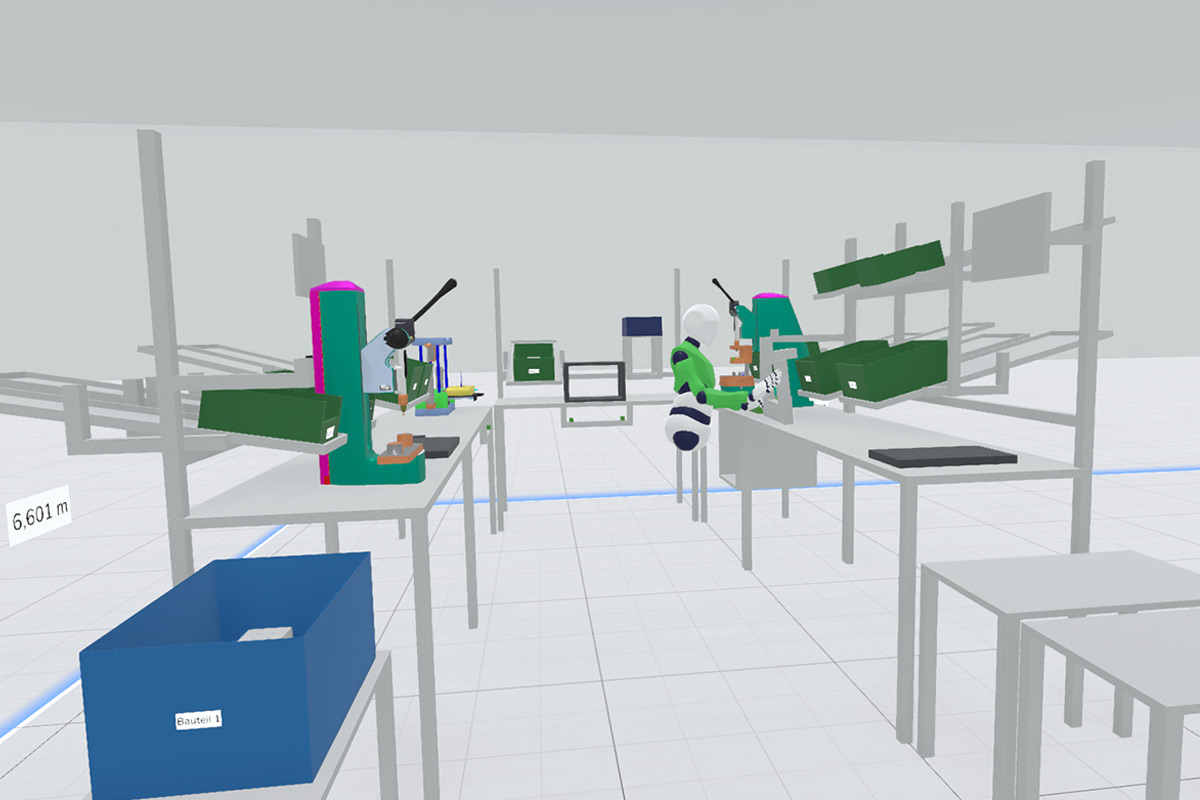

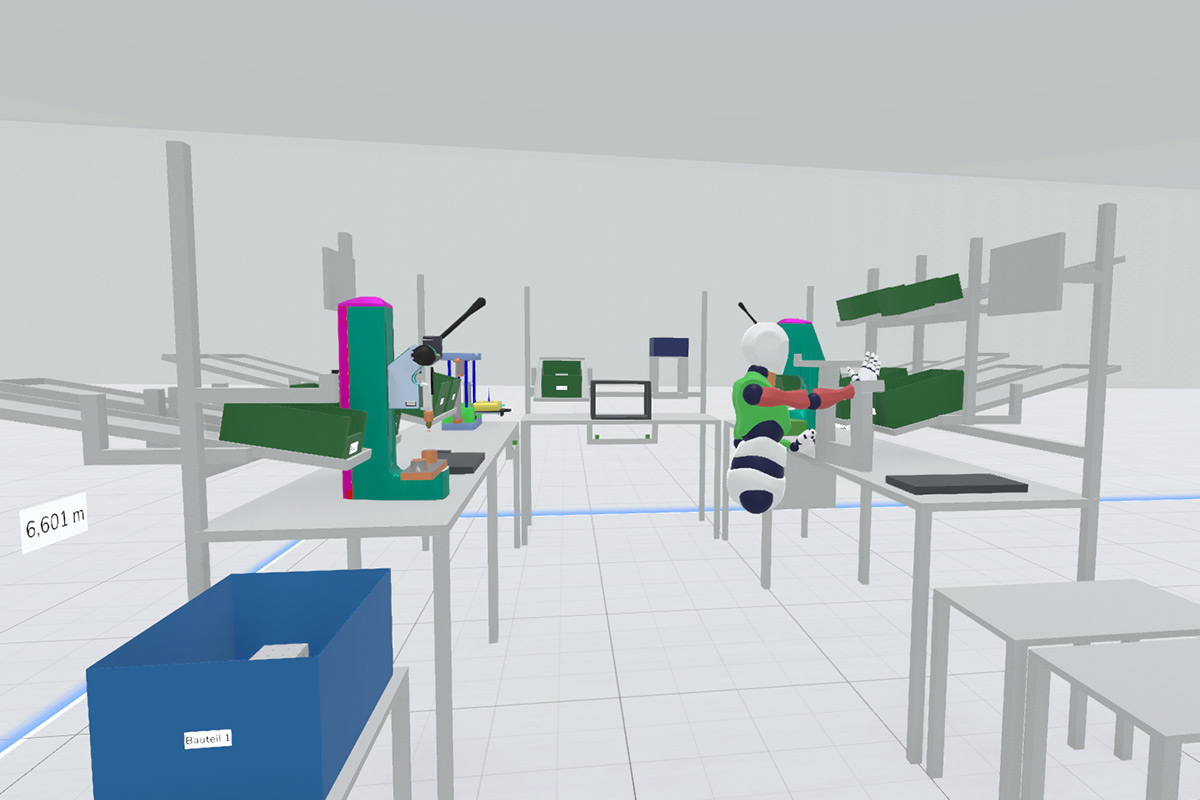

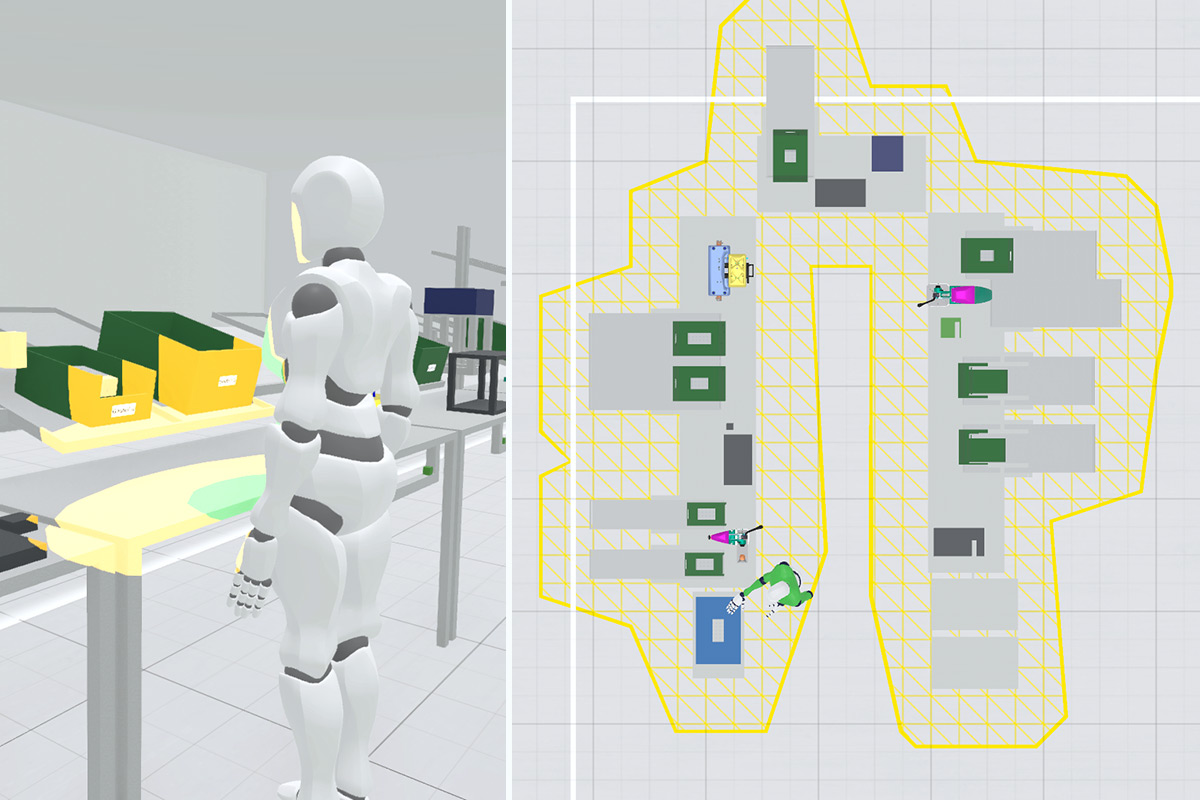

The software addresses one of the most pressing challenges in modern production: maintaining an up-to-date digital twin of your facilities and processes. As industry demands continue to change, it’s essential that production environments are quickly and precisely adapted to meet new requirements. The VR-powered platform makes this possible by enabling us to create and optimize virtual replicas of entire production halls, assembly lines, and workstations.

By integrating CAD data into the software, we can meticulously replicate existing production processes and identify potential improvements—all within a virtual environment. This ensures that when physical changes are made, they are both necessary and highly effective.

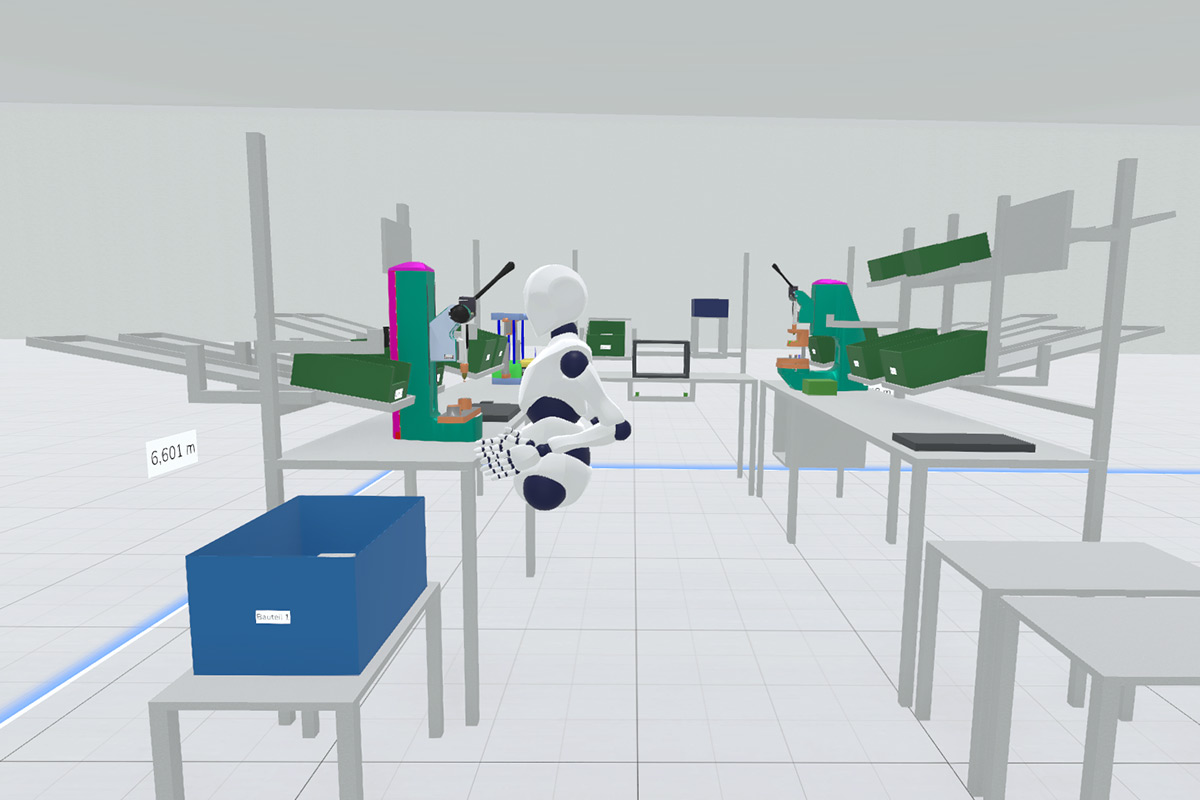

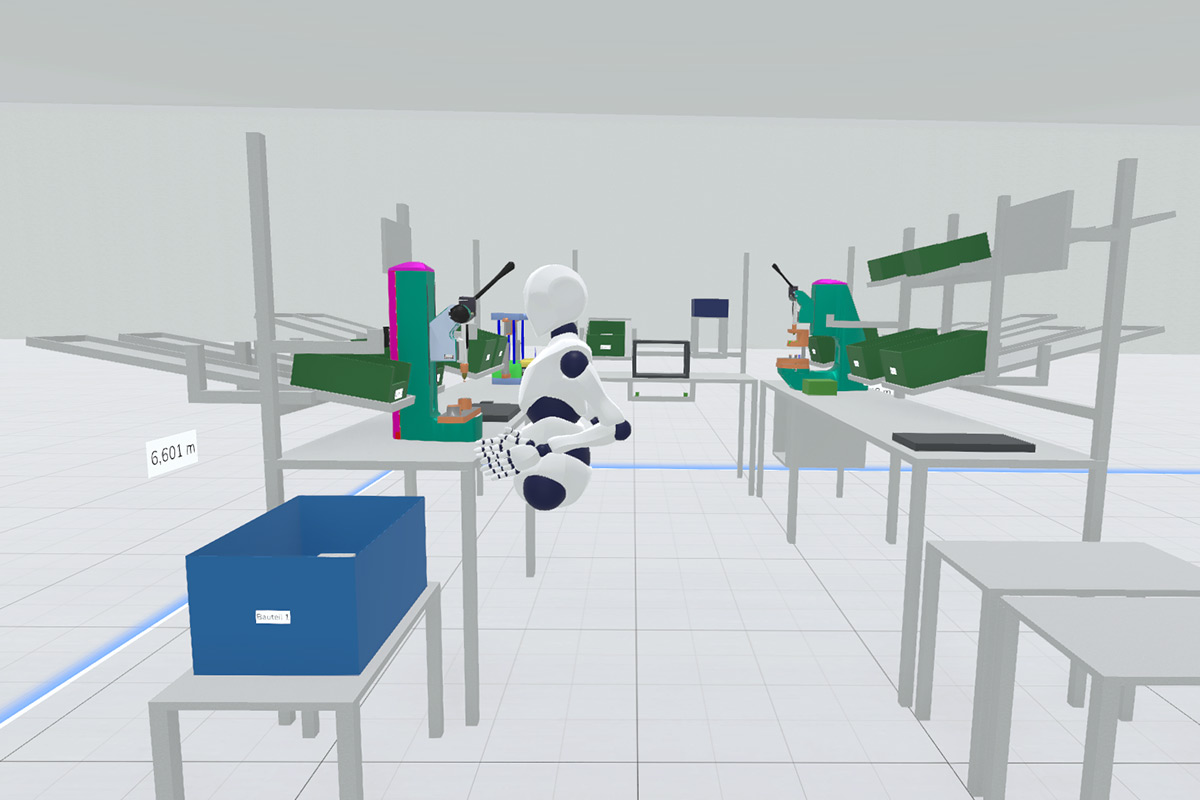

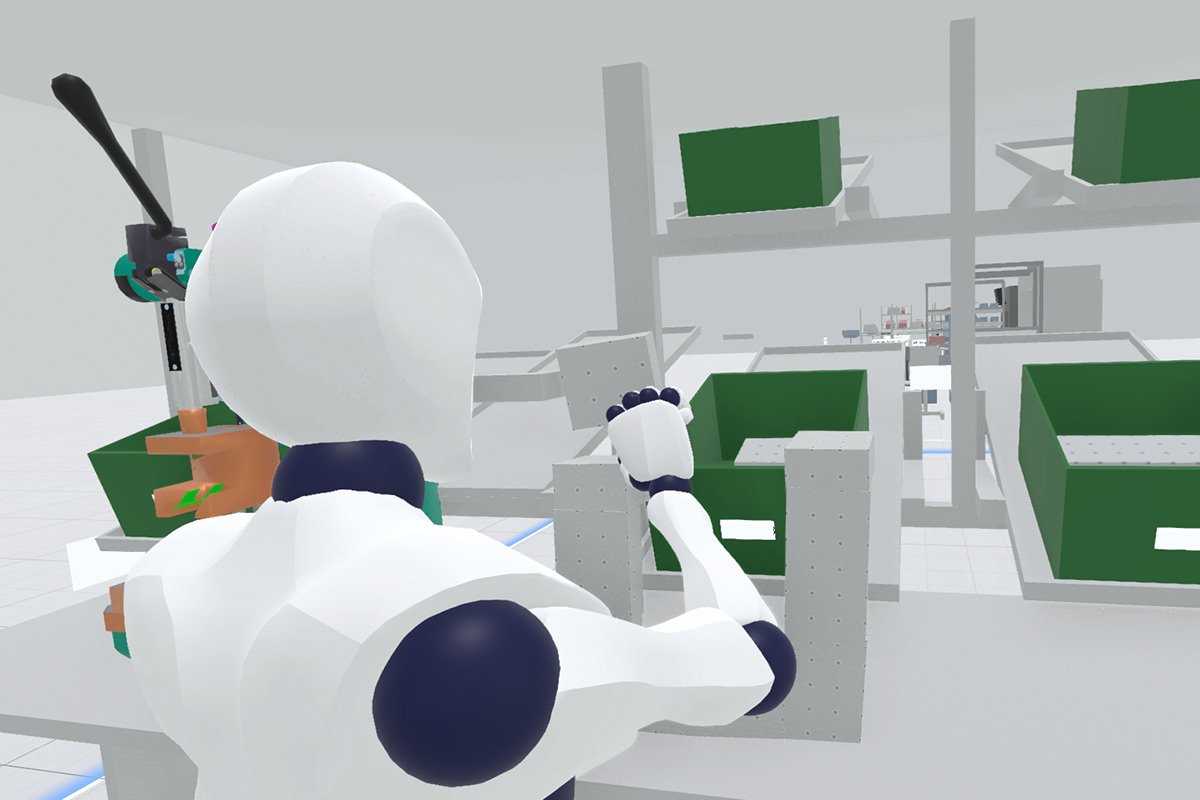

With this technology, we can simulate workstations in VR to spot potential bottlenecks before they occur in the real world. This proactive approach reduces downtime, minimizes costly errors, and ensures that physical changes are only made when absolutely necessary.

The software replaces the physical modelling of the workspace with a more accurate, flexible, and scalable solution that saves both time and resources.

Our clients benefit from ergonomic analysis capabilities, which allow us to visualize and optimize the physical demands placed on workers. By refining assembly lines for better ergonomics, we help reduce the risk of injury and improve overall productivity.

The technology also allows us to offer our clients a more interactive and immersive experience. By visualizing new assembly lines or products in VR, clients can gain a clear understanding of proposed changes before they are implemented. This not only fosters better collaboration but also ensures that our solutions meet their exact specifications.

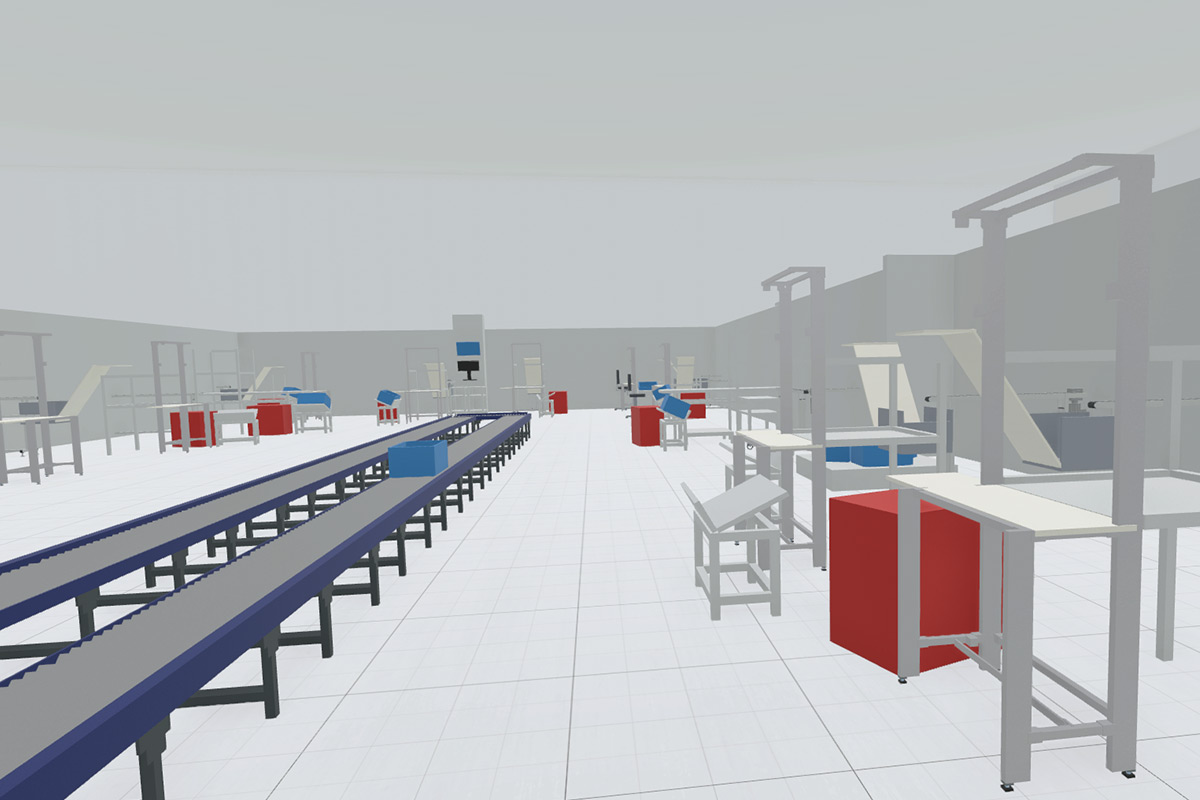

Having successfully implemented the technology at our Waldachtal site, we are exploring further applications at other facilities. For instance, we used the software to visualize and optimize the cleanroom in Neuhaus, with potential to integrate new technologies like automated guided vehicles. Similarly, our Rochester warehouse will be virtually modeled to evaluate its potential as a future production site.

The potential applications are vast. Beyond optimizing material flow and machinery placement, we see opportunities to expand its use into intralogistics and additional assembly lines.

The VR-driven approach offers the same benefits as traditional simulations—reduced time and costs, higher quality, and increased process reliability—while providing an even more realistic and comprehensive view of the production environment.

With this technology, we reaffirm our commitment to providing state-of-the-art, customized solutions for our clients. Whether you’re looking to optimize your current production processes, explore new technologies, or simply gain a more detailed understanding of your operations, our team is ready to assist you.

To discover how our VR-solutions can benefit your business, we invite you to get in touch with our experts. Let’s discuss how we can tailor this innovative tool to meet your specific needs and drive your business forward.

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

For more information about our VR solutions, please contact our team.

We look forward to hearing from you.

Thierry Arnaud

Vice President - Sales & Marketing Europe

Bill Ruth

Vice President - Sales & Marketing