Dimensionally stable at 200 degrees Celsius

SustaPEEK sample holder ideal material in the vulcanisation process

What plastic is suitable as a sample holder in a vulcanisation furnace? An enquiry that Thomas Schölzel, Product Manager thin sheets & foils at Röchling Industrial, doesn't receive every day. The vulcanisation furnace is a measuring device that maps the heating process during continuous vulcanisation. The sample to be heated is located on the sample holder. This means that a material is required that remains temperature-stable even at temperatures of around 200 degrees Celsius and at the same time only absorbs a small amount of microwave radiation.

SustaPEEK: good mechanical properties and excellent dimensional stability

A construction made of metal and PTFE/GF film quickly proved unsuitable. In their search for a suitable material, the furnace’s developers came across Röchling’s high-performance plastic SustaPEEK (polyether ether ketone), which because of its properties is perfectly suited to this application. "Our SustaPEEK material has proven itself in many demanding industrial applications. PEEK is characterised above all by its very good mechanical properties and excellent dimensional stability even at high continuous operating temperatures of up to 250°C," according to Thomas Schölzel.

SustaPEEK sample holder holds sample securely during vulcanisation

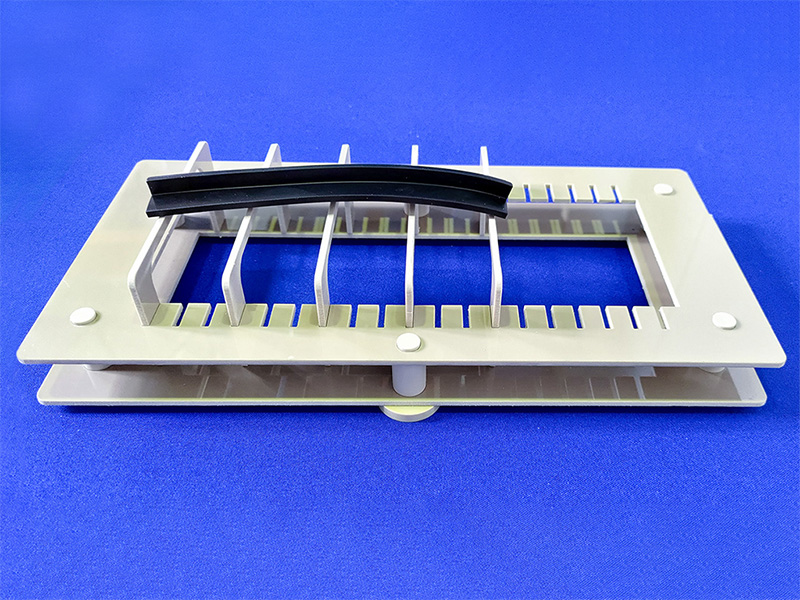

After consulting Thomas Schölzel, the developer chose a three Millimetre thick calendered sheet made of SustaPEEK for the design of the sample holder. SustaPEEK also has critical properties in terms of workability. It can be processed quickly and cleanly using a water jet. Because a variation of the web spacing was necessary for the application, a plug-in system was selected for the design. The parts required for this could be obtained from a sheet by using water jet cutting. The sample holder is placed in the vulcanisation furnace and holds the sample securely during heating.

Heating curve of a profile can be measured in the vulcanisation furnace

Vulcanisation furnaces are used for the production of elastomeric plastics. Rubber polymer and admixed fillers are heated for this purpose. This vulcanisation process transforms the rubber mixture from a plastic state into an elastic state. This creates an elastic plastic, which is well-known as rubber. The foaming of rubber also enables a lower density and better insulation properties to be achieved. During heating, the foaming process can be measured. For this purpose, a piece of rubber profile is placed on the sample holder inside the furnace and heated simultaneously or sequentially with hot air, infrared radiation and microwaves, and the change in profile contour is measured.