Or: How can you strengthen your rotor blades for wind turbines?

Together with the ribs, the two spar caps in the rotor blade shells are, you might say, the skeleton of each and every rotor blade of a wind turbine, and they must be able with withstand very high loads for the entire life of the turbine. That makes it essential to deliver high component quality and to ensure that the best possible properties of the mix of fibres and matrix are achieved.

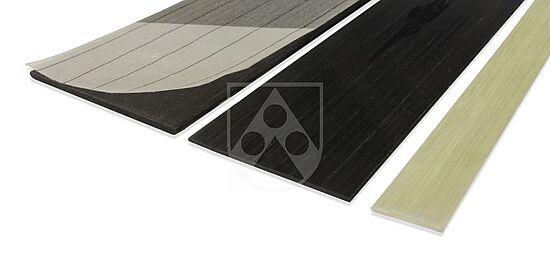

We offer you pultruded profiles for spar caps with

different fibre reinforcements

resin matrices

and cross-sections

Our profiles are manufactured in the pultrusion process. The continuous process enables us to manufacture almost endless profiles of a consistently high quality. The tensile forces prevailing during pultrusion make the reinforcing fibres very straight in orientation, thereby heavily reducing occurrence of the fibre undulations that occur frequently in other manufacturing processes.

Material - profiles for spar caps:

Fibre reinforcements:

- Glass fibre reinforcement

- Carbon fibre reinforcement

Resin systems:

- Epoxy resin

- Vinyl ester resin

- Polyurethane resin

- UV-curing resins, depending on the profile cross-section

Cross-sections:

With thermal pultrusion:

- Reinforcement with glass or carbon fibres possible

- Various cross-sections: width up to 200 mm, wall thickness 1.2 to 5 mm

UV-curing pultrusion:

- Only glass fibre reinforcement possible

- Wall thickness approx. 0.75 to 2.5 mm

Peel ply

Our profiles for spar caps for wind turbines are also available with a peel ply on request, removing the need to roughen the surface, e.g. by sand blasting, before fitting the profiles.

Your advantages:

Our pultruded profiles are pre-cured and quality-tested insertable components with clearly defined, very high mechanical properties. That allows excessive material defects such as fibre undulations or air bubbles to be eliminated from these profiles right from the start, enabling error rates, manufacturing risk and repair requirements for the spar caps to be drastically reduced. The mould occupancy time for the rotor blade shells is also much shorter using this method than for spar caps produced in the traditional manner.

Summary:

High mechanical properties:

- Advantages of the pultrusion process compared with resin infusion

- Higher volumetric fibre content

- Better fibre orientation

Reduced manufacturing risk:

- Pultrudate is tested in advance according to defined criteria - only flawless material is used in the rotor blade

- Material defects that can arise in the spar cap area when rotor blades are manufactured in the traditional manner can thus be eliminated almost entirely

Shorter mould occupancy times

Technical data - Profiles for spar caps

| Test method | Dimensional unit | EP-CFK (D343) | VE-CFK (D745) | VEGZ-LP (D677) | EPGZ-UV (UV cured) | |

|---|---|---|---|---|---|---|

| Fibre types | Carbon (50K) | Carbon (24K) | Glass | Glass | ||

| Resin types | EP | VE | VE | EP-based | ||

| Density | ISO 1183 | g/cm3 | 1.6 | 1.5 - 1.6 | 2.1 | 2.0 |

| Volumetric fibre content | % | 66 | 65 | 65 | 64 | |

| Tensile strength (II) | ISO 527 | MPa | 2000 | 2400 | 600 - 800 | 1500 |

| Tensile modulus of elasticity (II) | ISO 527 | GPa | 150 | 165 | 45-60 | 45-50 |

| Flexural strength (II) | ISO 178 | MPa | - | 1200 | 700-1000 | 890-1020 |

| Flexural modulus of elasticity (II) | ISO 178 | GPa | - | 120-140 | 50-55 | 35-45 |

| Pressure resistance (II) | ISO 14126 | MPa | 1000 | - | 450-800 | - |

| Compression modulus of elasticity (II) | ISO 14126 | GPa | 145 | - | 50-55 | - |

(II) = relative to the profile longitudinal direction

The figures given above are mean values obtained through continuous statistical checks and tests. They are provided as an indicator of quality only and do not establish any warranty unless and until expressly agreed in a purchase contract.