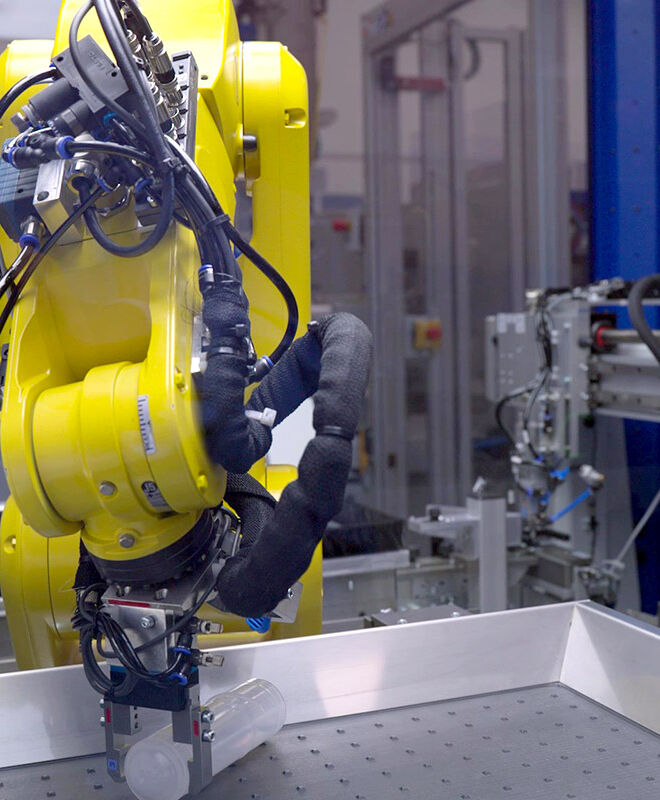

Röchling Medical supports you in the completion of your product, with a wide range of individual assembly and finishing steps. Whether fully automated, semi-automated or manual, we develop the ideal assembly solution and realize your customized end product in a controlled environment, with a deep understanding of application-specific requirements.

With sophisticated assembly capabilities, we realize the manufacture of your complete product.

In-house or in cooperation with our qualified partners, we offer you a wide range of options, for example:

In addition to plastic and metal components, we also assemble electronic components such as RFID chips or NFC tags, whose coding we can handle for you in close cooperation with our partners. Depending on the complexity and series sizes, we select the ideal level of automation for the assembly and finishing of your product. In this way, we guarantee you the most efficient and economic solution for your product.

In addition to our assembly options, we offer versatile surface finishing and printing solutions.

We determine the most suitable finishing technology, depending on the material, specification and area of application. For labeling and individualizing, we use state-of-the-art printing processes, some of them also under controlled cleanroom conditions:

Depending on the individual product and assembly line, these processes can be carried out directly inline. Integrated testing processes ensure that your product is realized in a high-quality, cost-efficient manner.

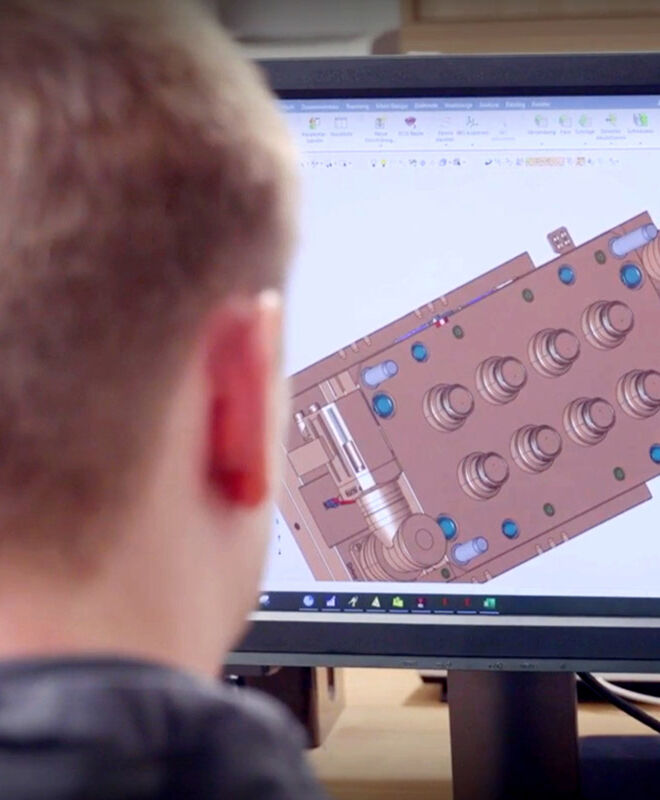

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

For more information about our custom assembly and finishing options, please contact our team.

We look forward to hearing from you.

Thierry Arnaud

Vice President - Sales & Marketing Europe

Bill Ruth

Vice President - Sales & Marketing