Röchling Medical has more than 60 years of experience in the processing of thermoplastics in the blow molding process. In this highly specialized area we offer a unique range of process technologies in cleanrooms GMP classes C and D:

This enables us to produce a wide range of pharmaceutical primary packaging options, for liquid, solid and powdery pharmaceutical dosage forms, as well as consumables for diagnostic liquids. Container sizes range from small vials to large multi-liter canisters for diagnostics.

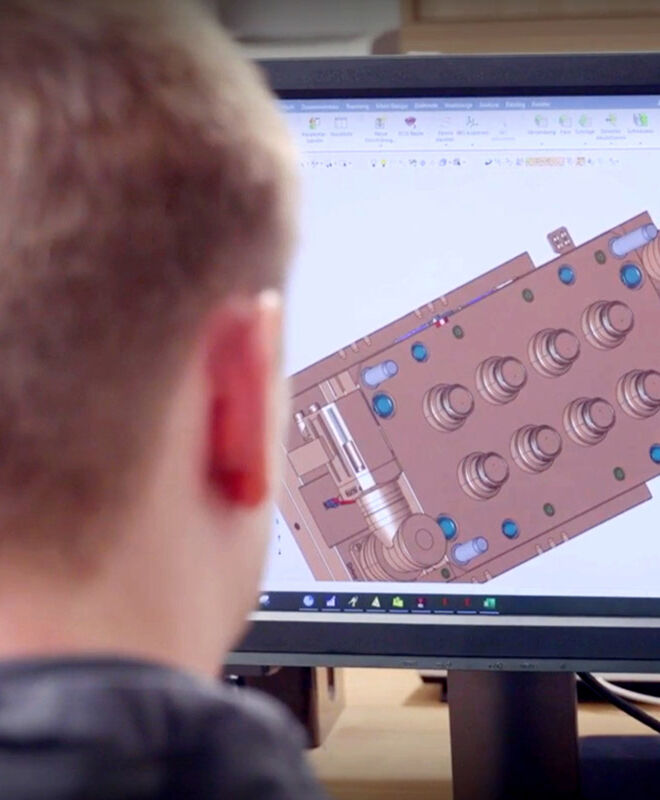

Extrusion blow molding allows the realization of complex functional designs and extreme shapes, e.g. containers or reagent cassettes used in diagnostic analyzers. Multilayer technology enables the targeted use of different material layers to achieve a combination of specific properties – for example optimised barrier properties to protect sensitive active ingredients such as veterinary vaccines, but also the integration of functional elements such as transparent viewing strips.

Injection blow molding is an efficient processing method in which a preform is first injection molded and then formed into the end product using the residual heat. In addition to standard plastics (PE, PP, etc.), we also use injection blow molding to process engineering plastics, such as COC or COC, e.g. for highly transparent injection vials.

Advantages of injection blow molding include seamless necks and bases and precise neck shaping of containers that ensures exact fit and sealing of closures. Injection blow molding is also a very low-waste production process which makes it comparably sustainable even at high volumes.

Stretch blow molding (also referred to as injection stretch blow molding) is a special form of blow molding. The stretching process at temperatures close to the crystal or glass melting point causes molecular changes that significantly improve the mechanical properties of the material. Stretch blow molding can produce stable containers even with thinner walls compared to other blow molding processes. Stretch blow molded PET containers have a high transparency and surface gloss.

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

At our global locations, we cover a wide range of manufacturing technologies, enabling us to find a suitable, customized solution for individual requirements.

For more information about our competences in cleanroom blow molding, please contact our team.

We look forward to hearing from you.