Customized Packaging & Logistics Solutions

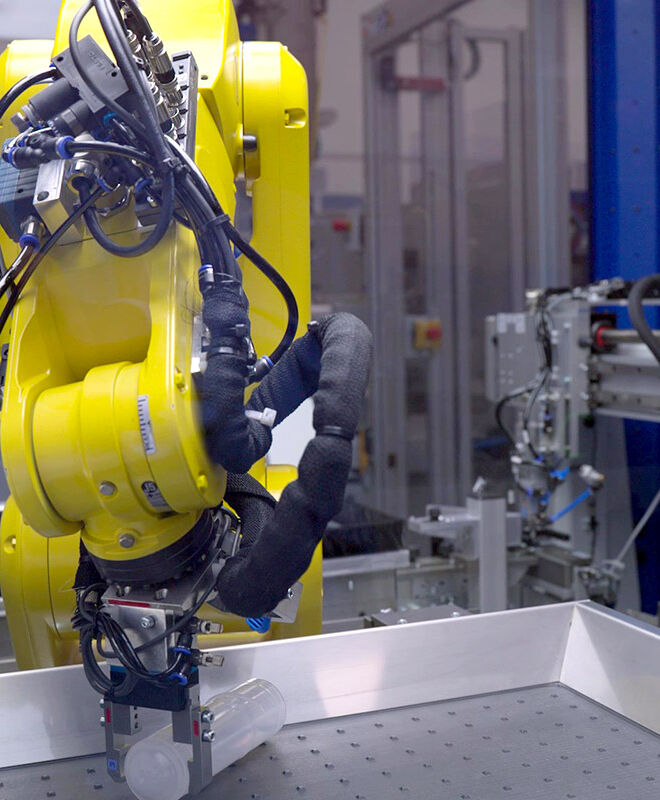

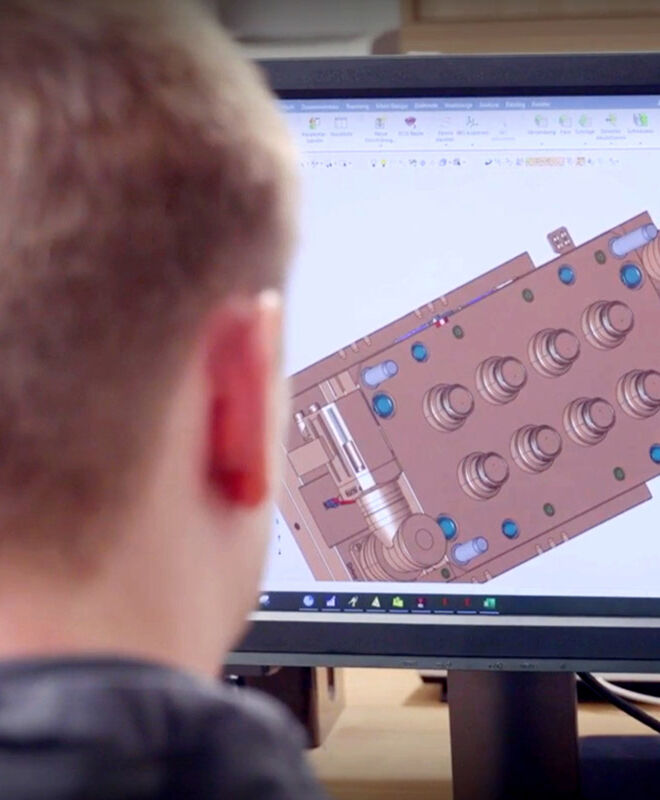

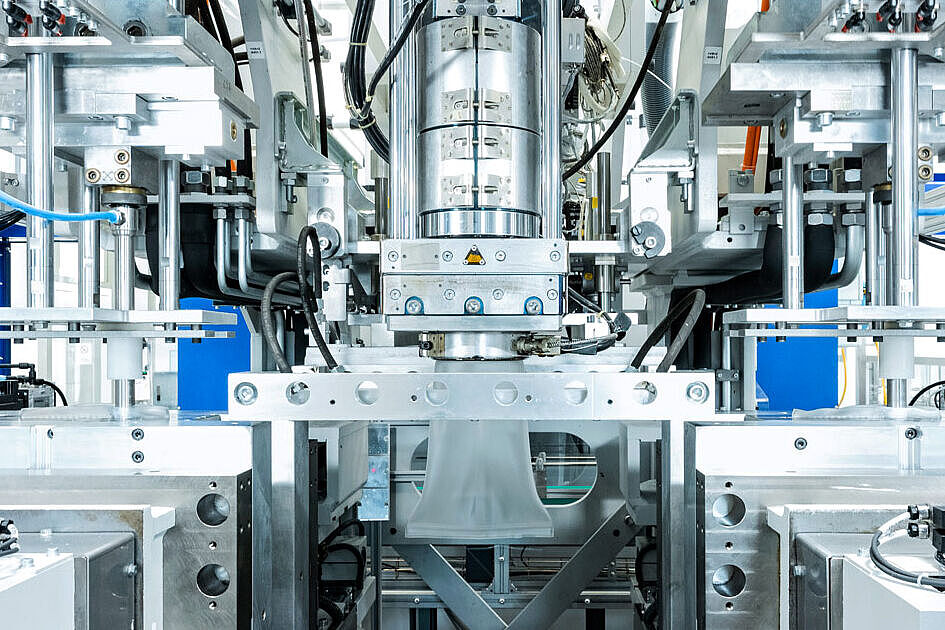

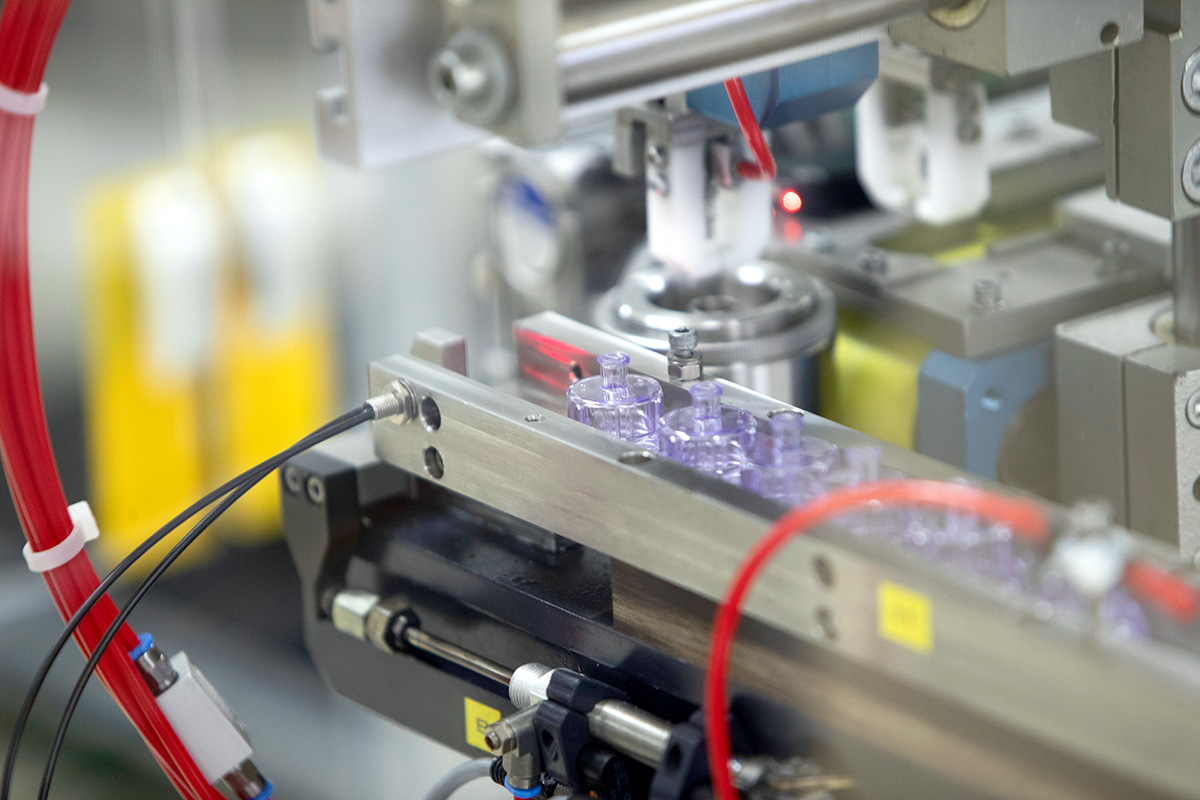

Thanks to our in-house packaging development , we are able to offer the optimal packaging solutions to deliver pharmaceutical primary packaging or drug delivery products safely to your processing lines.

For the customized packaging of medical devices we work closely with certified partners. Our packaging concepts take into account individual sterilization requirements, transfer processes at filling or processing lines, general transportation requirements and environmental goals. We offer highly customized packaging concepts according to ISO 11607 as well as standard solutions.