Application & Areas of Use

Used primarily in oral surgery as part of regenerative bone augmentation, dental syringes are an important part of the surgical process.

The precise placement of bone substitute material requires the use of such syringes, in which the material – which can also be hydrated if necessary – is stored in the syringe under aseptic conditions until it is applied to the jaw.

By using the dental syringe, the moistening of the biomaterial as well as the application into the bone can be carried out more efficiently and in a more controlled way in a closed system compared to conventional methods, thus also significantly minimizing the risk of contamination.

Product Features Overview

Röchling Medical dental syringes have a highly ergonomic design to allow one-handed use in bone grafting dentistry settings and to ensure good visibility during surgery.

Our syringes are tightly curved and fitted with a rotatable plunger that allows bone cement to be applied to the posterior region of the jaw. Röchling Medical dental syringes have a highly ergonomic design that allows for one-handed use in bone augmentation dentistry and ensures good visibility during the procedure. Our syringes are tightly curved and equipped with a rotatable plunger that enables the application of bone cement in the posterior region of the jaw.

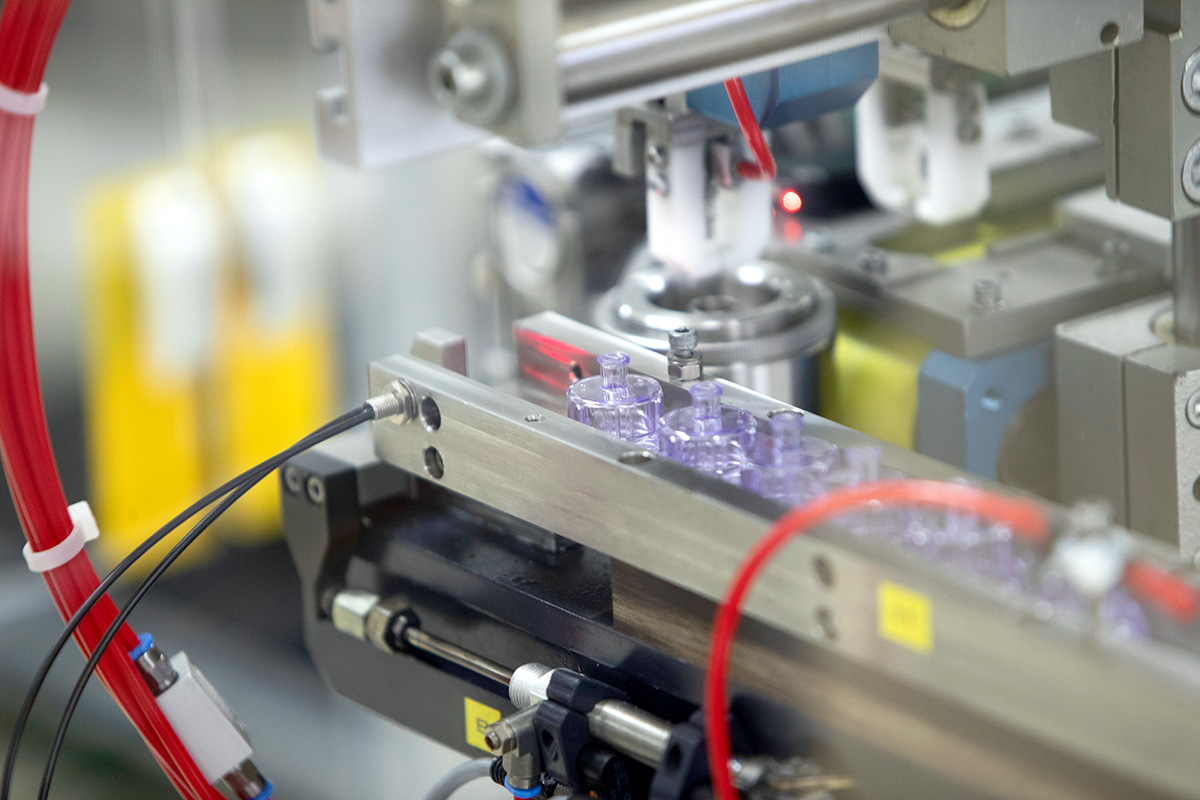

Depending on the intended use, two different versions are available: a syringe unit with a closure element for the application of paste-like bone cement and a syringe unit with a filter and closure filter for the administration of granular bone cement mixed with liquid.

- Developed for practical one-hand application

- Application of pasty and granular bone cement

- Curved syringe section with rotatable plunger

- Use of sintered cores that are virtually free of burrs

Our Expertise

Expert in Complex Designs

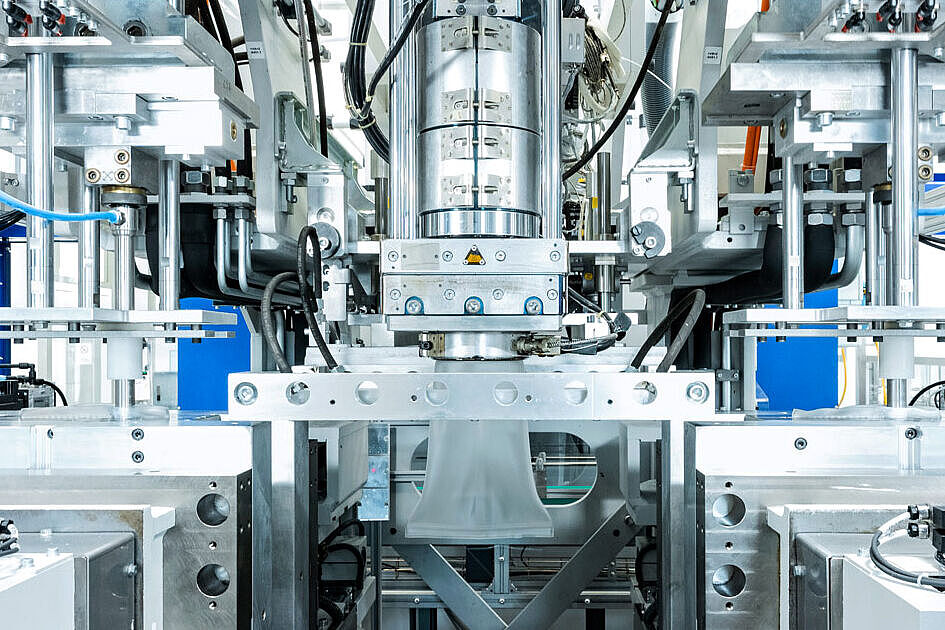

Röchling Medical’s expertise in injection molding enables us to produce dental syringes to precise ergonomic design standards. Our design expertise, tool-making knowledge, experience with curved tool cores and customer-focused project support is channeled into the manufacture of these parts, which requires the construction of five custom-designed injection molds. The two injection-molded parts and one externally purchased O-ring that make up the dental syringes are manually assembled under ISO 8 cleanroom standards. Flawless quality is guaranteed by visual inspections during series production.

Tool-making Expertise

We are experts in designing and manufacturing tools and injection molds for the production of complex plastic products that do not compromise on quality or accuracy.

Efficiency and Control

Our dental syringes redefine the industry standard by allowing for biomaterials to be hydrated and applied to the surgical site as part of a closed system, to minimize contamination risk.

Cleanroom Conditions

Given that dental syringes are used in surgical settings for the application of sensitive bone substitute material, we adhere to ISO 8 cleanroom standards in the production of these and other parts.

Customized Packaging

For the packaging and labeling of our products, we design individual solutions tailored to the customer and the application.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for medical applications and customized design options, please contact our team.

We look forward to hearing from you.

Your Contact

Thierry Arnaud

Vice President - Sales & Marketing Europe