Application & Areas of Use

Hemodynamic monitoring sensors are primarily used for the noninvasive monitoring and analysis of the heart’s pressure waves, the vascular system and blood.

As a multifaceted sensor, it can be used to generate data on various aspects of the cardiovascular system, including blood pressure, blood flow, volume status, vascular tone, cardiac function and pulmonary status. The results generated are comparable to invasive monitoring in terms of continuity, accuracy and waveform dynamics, so no performance-related compromises have to be made.

As a noninvasive procedure, there are many benefits for the patient: fewer complications, minimal risk of infection through contamination and faster patient recovery.

Product Features Overview

Hemodynamic monitoring sensors have to provide maximum comfort for the patient and user in addition to all the necessary functions.

The heart rate sensors manufactured by Röchling Medical consist of two main elements: a reusable mouse unit and a disposable sensor housing. They are compact, ergonomic and optimized for use in either hand.

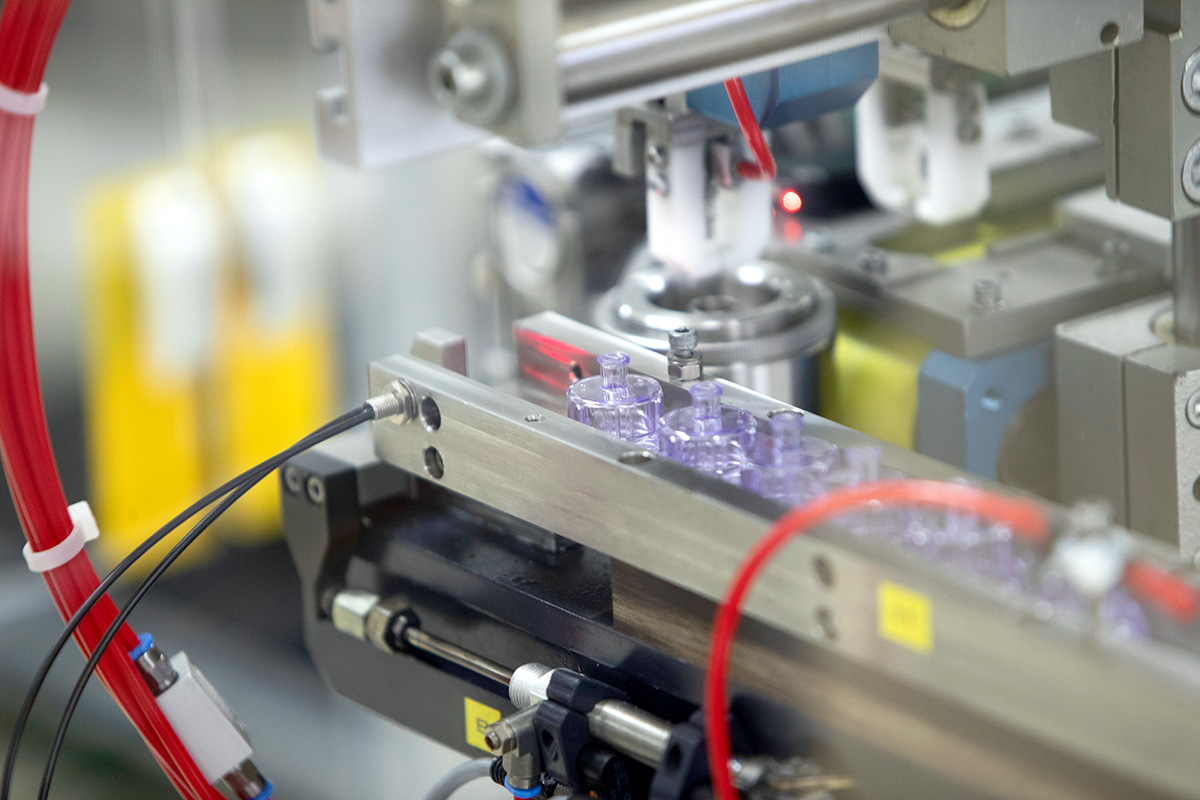

Available in small, medium and large sizes, the assembly consists of about 40 complex individual parts, including inflatable bladders, high-gloss light pipes, a specially encoded RFID chip and microinjection-molded parts.

- Injection molded disposable sensor housing

- Full in-house assembly

- Inline leak test

- Packaged in customized presentation boxes

Our Expertise

Advanced Manufacturing

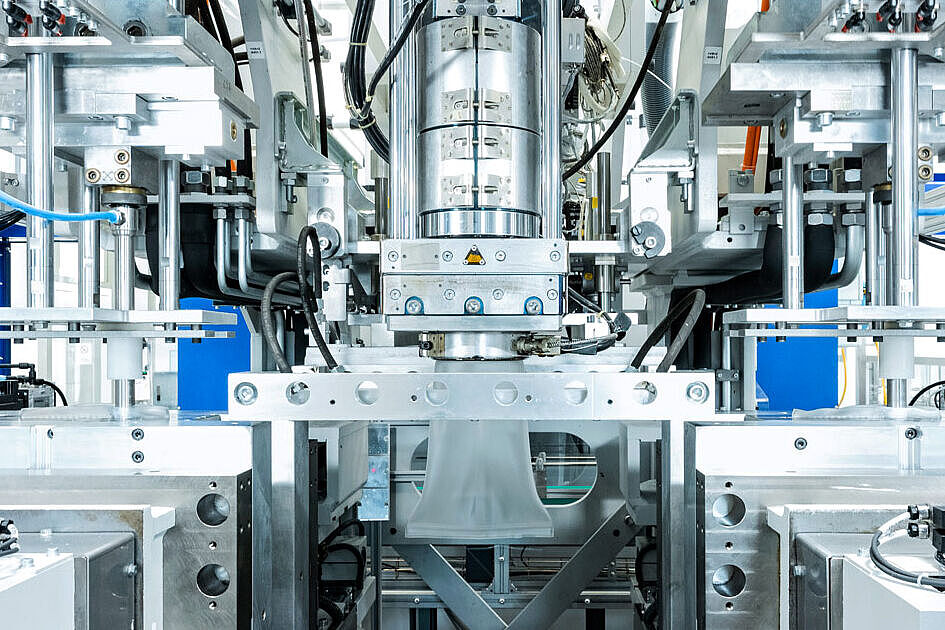

At Röchling Medical, we combine intelligent downstream processing steps with classic manufacturing. After manufacturing by injection molding, our components for the hemodynamic monitoring sensor are further processed directly in the cleanroom. The assembly line specifically designed for this product includes processes such as laser marking, pad printing, ultrasonic welding, bellows bonding, and assembly, during which quality is controlled and guaranteed with inline tests.

Complex Part Production

At Röchling Medical, we specialize in the manufacture of complex parts using processes such as injection molding, with a focus on quality, compact and ergonomic design, and accuracy.

Design and Development Expertise

We provide product development support via, for example, preliminary models and prototypes manufactured in-house to perform state-of-the-art functional tests and assembly trials.

Sophisticated Toolshop

Our flawless tools are the basis for smooth production. Our in-house tool shop specializes in the design, construction and maintenance of complex, high-precision prototype or series injection molds.

Individual Automation Solutions

We rely on intelligent automation solutions whenever they mean the best results for our customers. Manual, partially automated or fully automated – our manufacturing concepts are as individual as our customers' requirements.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for medical devices and customized design options, please contact our team.

We look forward to hearing from you.

Your Contact

Thierry Arnaud

Vice President - Sales & Marketing Europe