Application & Areas of Use

With many years of experience, Röchling Medical manufactures mixing systems that enable patients to mix and administer their own medications. The mixing and injection systems are designed for safe, easy preparation of lyophilized drugs for administration by medical professionals and self-administration by patients. In the all-in-one transfer device, lyophilized drugs are reconstituted and then directly injected. For some patients, these systems are essential for survival. With our know-how, we are able to produce at high volumes, reliably, on time and in the highest quality.

Product Features Overview

The mixing systems consist of a single unit that is placed on top of a small container holding a powdered drug. A syringe pre-filled with dilution liquid is fitted to the end of the mixing system. The liquid now passes into the small container with the drug so that the two components are mixed. By turning the entire mixing system upside down, the mixed drug is transferred back into the syringe. After reconstitution, the drug is available for immediate injection using the pre-assembled needle.

- All-in-one system for safe mixing and injection of lyophilized drugs

- A drug delivery system that is convenient and easy to use

- Simple preparation, administration and disposal

- CE marked and FDA registered

Our Expertise

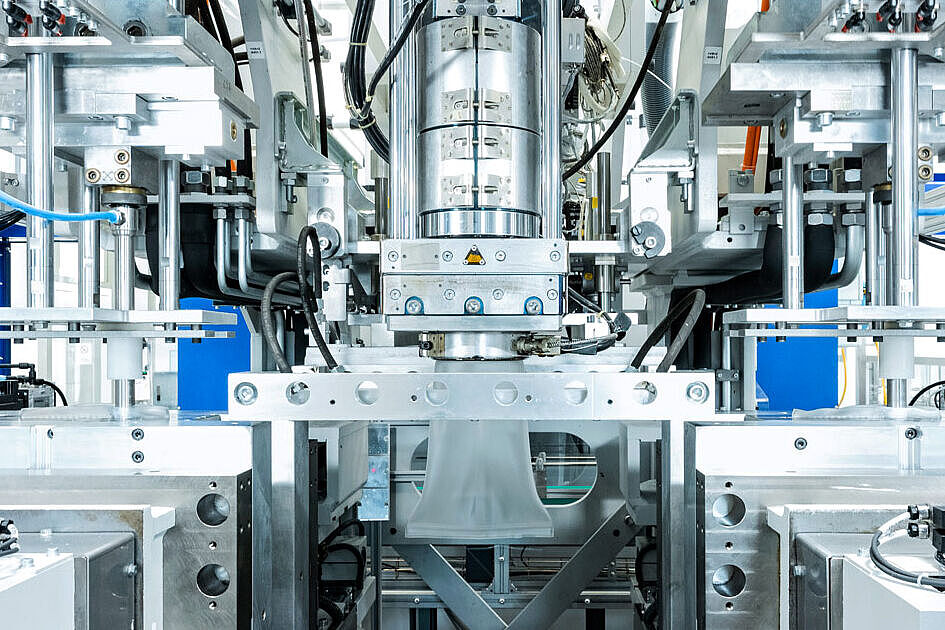

Full In-House Production

We manufacture the complete mixing systems at high volumes in accordance with the highest quality requirements using semiautomated and fully automated systems. The entire manufacturing process is in our hands: from the production of injection-molded parts on certified machines to fully automated assembly and sealing of the articles in Tyvek blister packs right through to sterilization control and monitoring. We provide comprehensive documentation of the entire manufacturing process for regulatory purposes.

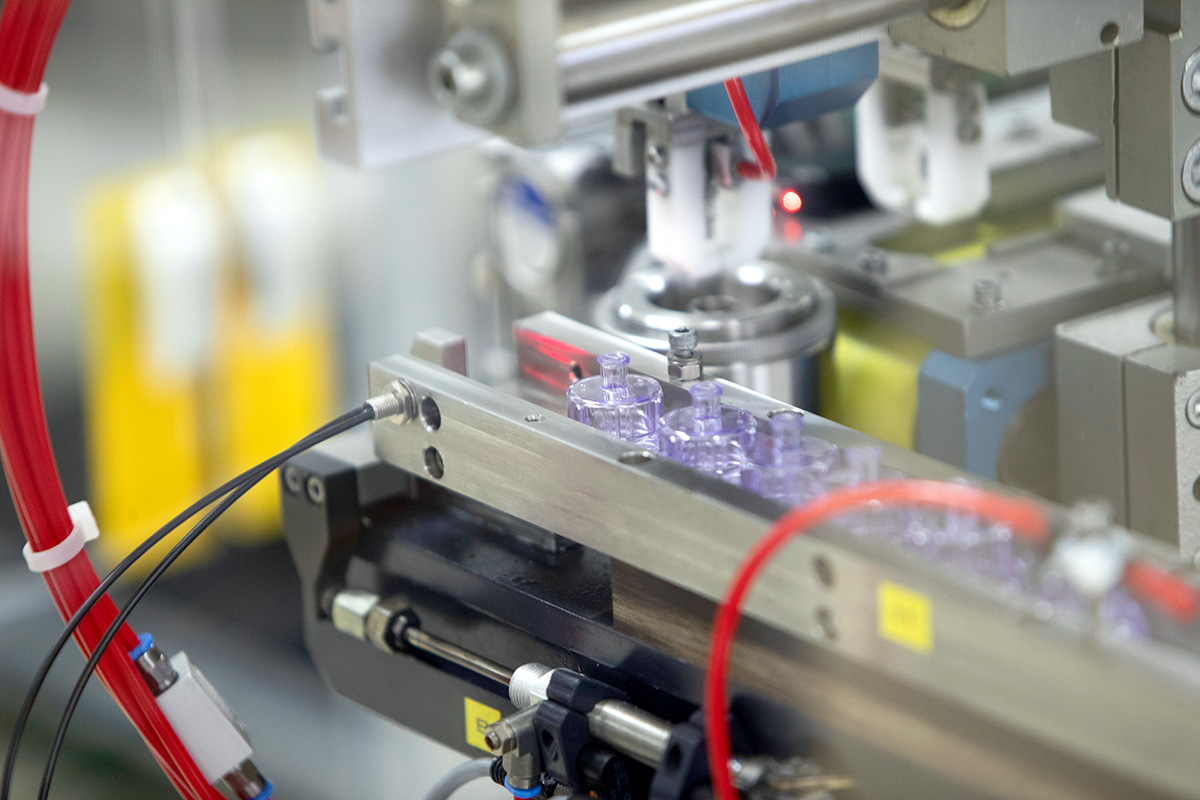

State-of-the-Art Facilities

Our cleanrooms are equipped with the full range of semiautomated and fully-automated equipment required for the production of complex products, allowing for complete in-house solutions.

Quality Monitoring

We use camera-based inspection systems to control the integrity of the finished products, enabling the strict quality standards at all times.

Injection Molding Expertise

Our validated injection molding machines are the heart of the production process, in which our experts produce high-quality parts.

Protective Packaging

The finished products are sealed in Tyvek blister packs to fully protect them during transportation and storage. They can be easily removed from the blisters and are ready for immediate use.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our drug mixing and delivery solutions, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing