Application & Areas of Use

The packaging of veterinary medicines plays an important role in protecting the contents. The most important function of primary packaging is to ensure shelf life and maintain the stability and efficacy of the contained drugs. Material properties and the manufacturing process are crucial in this respect. To protect against spoilage and maintain drug efficacy, vaccine containers for livestock and farm animals require particularly effective barrier properties.

Features & Properties

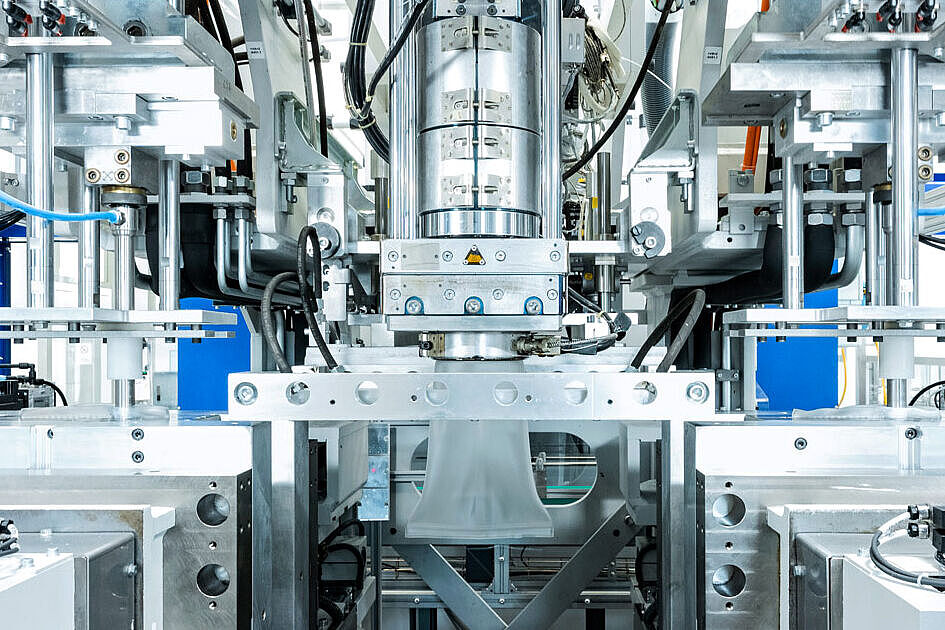

For superior barrier properties, we manufacture plastic injection vials for the veterinary market in multiple layers, using the co-extrusion blow molding process.

Two or more different plastics are joined together in this process. Combined, they exhibit properties that they do not have when processed individually. Depending on the material combination, they provide an appropriate gas and permeation barrier that effectively protects the vial contents from external influences such as moisture, oxygen or UV radiation. The high-quality medications contained are thus protected and their shelf life is extended.

Vaccine vials made of plastic are also lightweight and unbreakable. This is particularly advantageous in the field of veterinary medicine, where large-volume containers are used more frequently.

- Multi-layered for optimal barrier properties

- Lightweight and break-resistant

- Compatible with standard veterinary injection devices such as injection pistols

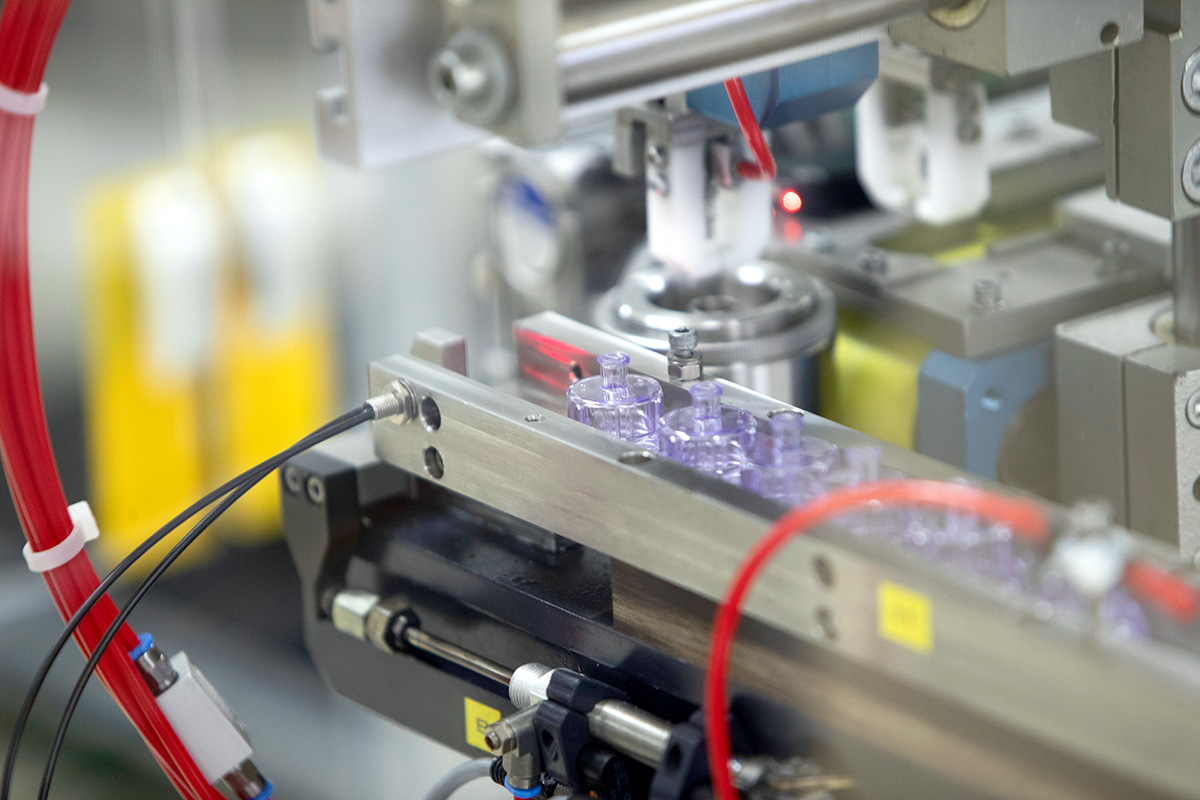

- Manufactured in cleanrooms certified according to GMP C and D

- 100% in line camera controls

Our Expertise

Specialists in Customized Plastic Primary Packaging for Veterinary Pharma

The standards for veterinary medicinal products are no less critical than those for human pharmaceuticals. With our high-standard cleanroom concepts and many years of experience in the animal health market, we meet our customers’ requirements for low-germ, functional, high-quality, and thus safe, primary packaging. We are a preferred supplier of leading veterinary pharma companies for standard and customized packaging solutions.

Preferred supplier for veterinary pharma

Röchling Medical has long experience as a supplier of primary containers for the animal health markets.

Design expertise for customized solutions

We develop customized container solutions to your requirements, whether multiple layers, special features or special sizes.

Standard range of injection and infusion bottles

Our standard range includes bottles for injection and infusion in a number of standard sizes.

Fullfilling high quality requirements

We produce, assemble and package according to ISO 15378 in GMP class C and D clearooms.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for veterinary medicine, please contact our team.

We look forward to hearing from you.

Thierry Arnaud

Vice President - Sales & Marketing Europe