Improving the Carbon Footprint of Single Use Medical Devices

The high share of single use instruments in medical procedures is partly a hygienic imperative but is also an increasing environmental concern.

A trocar is a sterile device used in minimally invasive procedures to provide access to the body for laparoscopic instruments. Over 13 million laparoscopic procedures are performed globally per year, using this single use device

How can the carbon footprint of the standard trocar be positively influenced by intelligent device design?

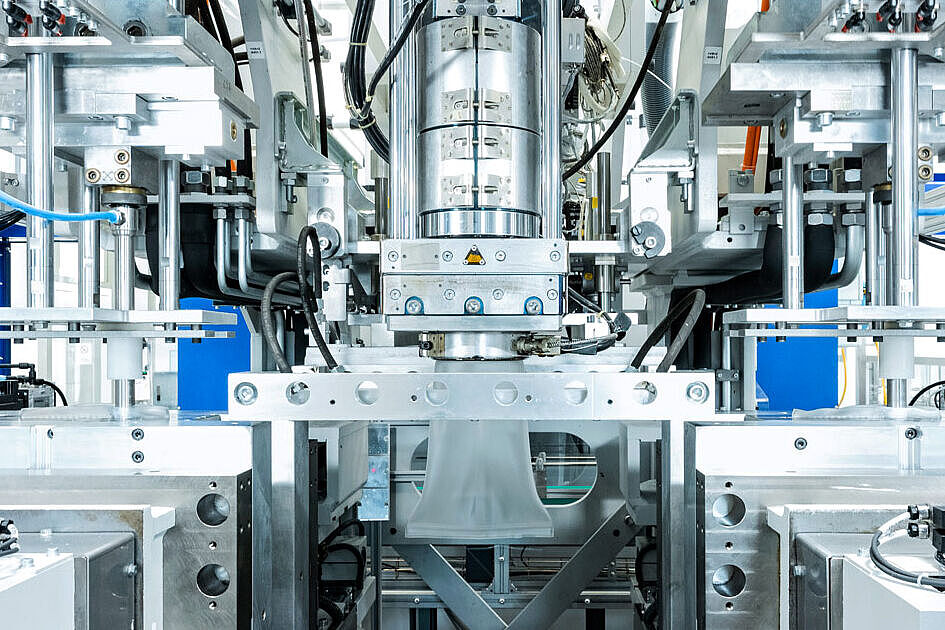

Röchling Medical has applied design-for-sustainability (DfS) principles to the development of a standard bladeless single use trocar made of plastic.

A Trocar re-designed based on Design for Sustainability principles

We analyzed the product comprehensively by examining all relevant design-related elements that have an impact on its sustainability:

1. Design Optimization for Material Usage

Reducing weight:

Using advanced simulations such as FEM and flow analysis we were able to slim down the design so that 32% of material could be saved without any loss in functionality or stability.

Reducing the number of components:

A standard trocar consists of a minimum of 12 parts. Our updated design consists of only 8 parts. This means a reduction in the number of required injection molds, as well as a significant reduction of process steps for assembly.

2. Design for Disassembly

Modularity of components:

A standard trocar usually does not have detachable connections. In our optimized design, the components are connected to each other by snap-fits. These hold securely during use, but are easier to assemble and, conversely, easy to disassemble again for disposal or reuse.

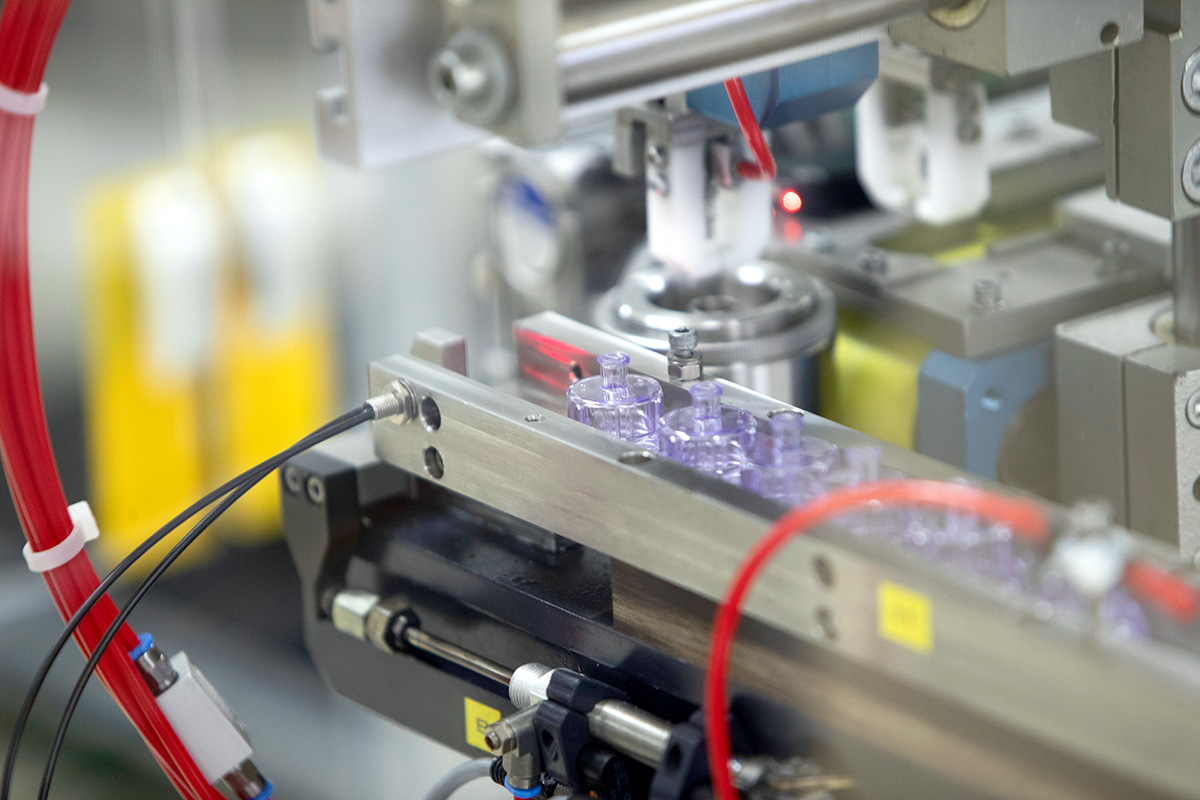

3. Material Selection

Many trocar components are conventionally made from polycarbonates containing BPA. We optimised the design for the use of more environmentally friendly materials, such as PP and biobased PLA. These materials do not contain any chemicals that might elicit health concerns.

Due to the modular design, the components can be easily disassembled for the recycling of the different materials.

4. Design for Recycling

Minimal material variety and recyclability:

In a standard trocar there are a minimum of five different materials. We reduced this to three different materials: PLA, PP and Silicone. PLA and PP are recycling-friendly alternatives.

Material identification:

To simplify material separation, the materials are clearly marked on the components of the trocar optimised by Röchling Medical.

The Result

In terms of material production and processing, the global warming potential of the trocar design optimised based on Design for Sustainability principles is reduced by 51% compared to a conventional trocar.

With 1 mio. sustainable trocars, 50 tons of CO2-equivalent could be saved. This is comparable to the CO2 emissions for one person of 27 flights from Frankfurt to New York.

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our sustainable design solutions, please contact our team.

We look forward to hearing from you.

Thierry Arnaud

Vice President - Sales & Marketing Europe