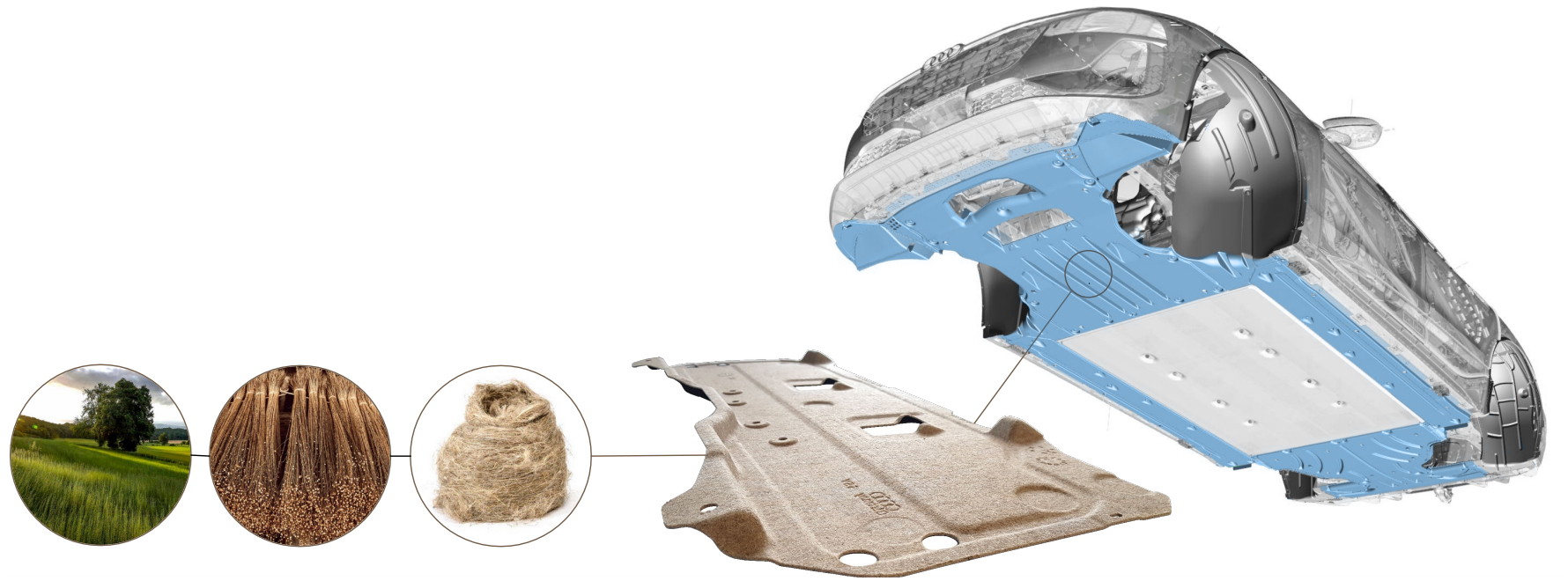

A Regrowing Vehicle Floor

Production-ready component made from natural fibers and recycled plastic

Underbody panels are manufactured in considerable quantities and account for a large proportion of the vehicle. Therefore, focusing on sustainability really pays off here.

Röchling Automotive's solution features two material alternatives: natural fibers replace glass fibers, and we use a recyclate instead of virgin polypropylene.

Significantly fewer carbon emissions

The use of renewable raw materials saves significant amounts of CO₂. An underbody with natural fibers reduces the ecological footprint by around 40 percent. The energy required for production even decreases by 80 percent.

Ready for everyday use and series production

The aim is to maintain the functionality of the components. That means the high requirements for wind load, stone impact, water penetration, ice, and snow must be met. And this must be to the same extent as for underbodies made of conventional materials.

We have tested the performance and safety of the underbody in collaboration with research institutes and a major car manufacturer. The newly developed materials and components have passed all safety tests and are therefore suitable for series production.