The sheet with the build-in hinge

Röchling Engineering Plastics has developed the closed-cell, foamed material Foamlite® especially for applications, in which it is a question of a combination of good mechanical properties and low weight.

Easy handling

The weight of finished components is of decisive significance in many fields

of application. Low weight plays a great role, by way of example, for the

logistics of smaller waste water tanks in water as well as environmental technology, and a light execution is also of use in tank roofs.

It is precisely in plant engineering where Foamlite® can make the most

of its advantages: Due to the excellent relationship of toughness, rigidity and

chemical resistance, Foamlite® is also suitable for roofs of tanks and plants.

The slight effort for lifting saves money and may also offer constructive advantages with regard to the lifting device. Moreover, Foamlite® can be very well welded with Polystone® P types in extrusion and hot gas welding techniques.

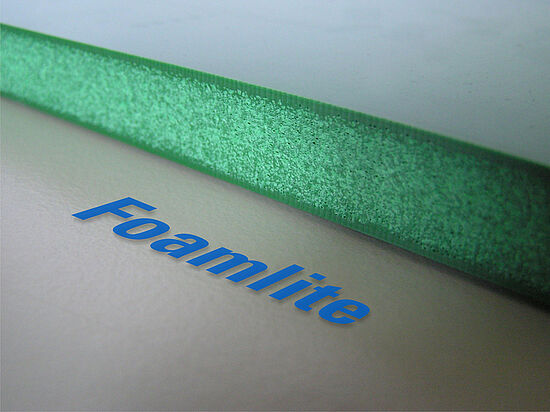

Hinge inclusive

The highlight: Polystone® Foamlite offers an “integrated hinge”. The material

possesses outstanding flexural fatigue strength, and can be bent more

than 40,000 times after a groove is machined with a simple router. This

means costly screwed-in metal hinges, which must be changed due to, for example, corrosion damage, are a thing of the past.

The product family Foamlite® is available in diverse executions and can

be adapted to meet individual requirements e.g. UV-resistant, antistatic, electrically conductive or flame retardant

Additional benefit

What is more, Foamlite® offers very good insulating properties by air being

enclosed in the foamed core. Foamlite® can be produced in practically any colour shade required.

The dimensions are varied as well: Foamlite® is even available as an extremely

wide sheet of up to 2,000 mm and up to 20 mm thick.