Select a different country or region to see specific content for your location.

Pharma

Plastic materials and parts for Pharma

Materials and parts for Pharma

The development of drugs is a lengthy and complex process. Manufacturer of pharmaceutical products place specific demands on machines, equipment and materials used. Our materials are worldwide used supporting the safe and economic development and production of drugs.

Typical parts include

Seals

Housings

Guides

Connectors

Agitators

Fixtures

Application examples

The performance and service life of materials used in the healthcare sector are influenced by a variety of factors. When choosing the right material, factors such as surface quality requirements, contact with cleaning agents, disinfectants, dimensions and/or tolerances are essential.

Selection of Medical Grade Products

- PEEK

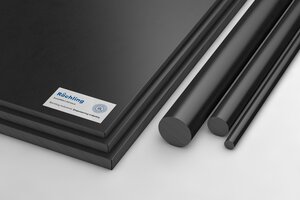

SustaPEEK MG black

- PEEK

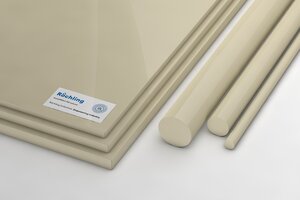

SustaPEEK MG natural

- PEEK

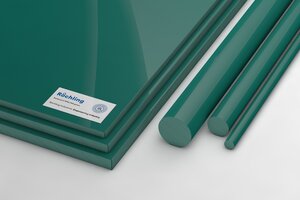

SustaPEEK MG blue BL

- PEEK

SustaPEEK MG red RD

Selection of Healthcare Grade products

- PE > PE-HD - PE 300

Polystone® G HG white

- PVDF

SustaPVDF HG natural