Lamigamid® 315

PA — PA 6 G

Characteristics

- Good dimensional stability

- Antistatic

- ATEX operational

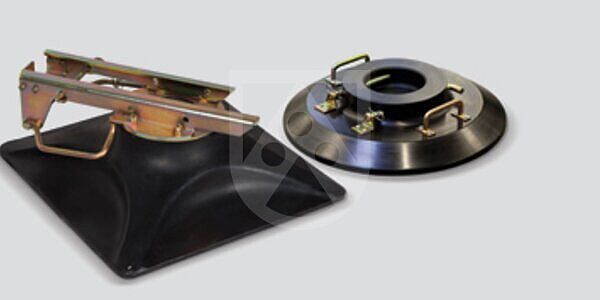

Application Examples

Technical Specifications Lamigamid® 315

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 1,15-1,19 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | ∼ 60 |

| Elongation at break | DIN EN ISO 527 | % | ∼ 5 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 3000 ∼ 3700 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | 2,5-6,5 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | ∼ 215 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Surface resistivity | Ω | 106 - 108 |