Trafoboard presented in Berlin

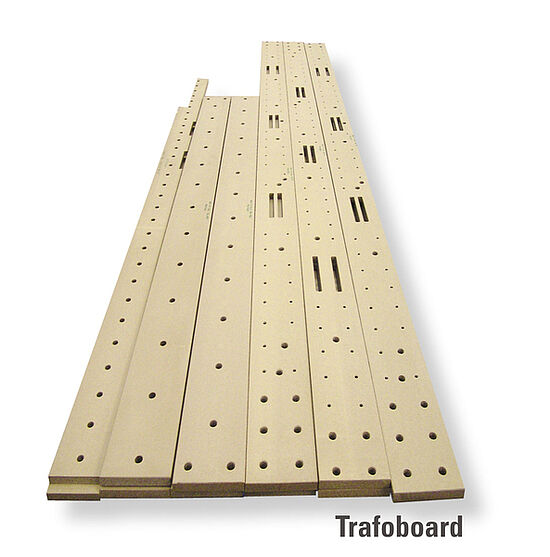

Haren - With Trafoboard, the Röchling Engineering Plastics Group is offering a new insulation material for high-voltage transformers, meeting the highest requirements in electrical properties.

Röchling Engineering Plastics has developed laminated pressboard glued on a polyester basis for the highest requirements in cooperation with a renowned manufacturer of the basic material pressboard. This new insulation material called Trafoboard had its premiere at the trade fair CWIEME-Coilwinding 2010 in Berlin, where it was presented to the international trade experts from the field of output transformer construction. The experts` interest in Trafoboard was unusually great, since there are only very few qualified suppliers of laminated pressboard.

Trafoboard HD-PG is a tightly compressed, laminated pressboard glued with polyester resin that comprises homogeneous, chemically very pure cellulose. To begin with, Röchling offers this insulation material in the standard format 2,050 x 1,050 mm and in thicknesses from 10 to 120 mm an. Finished parts over 120 mm thick can also be delivered on request.

World-wide machining network

With 30 world-wide subsidiary companies, Röchling Engineering Plastics has outstanding closeness to the market at its disposal. The machining locations in Germany, England, Italy, France, India, USA and as of October also in China are equipped with modern CNC-controlled milling machines for the production of insulation components made of Trafoboard and the traditional material Lignostone® according to customer drawings.

Electrical resistances

In a further step, Röchling works on Trafoboard sheets in larger sizes, which are bonded with a newly developed Phenolic resin system. For this bonding technology, Röchling has almost had a hundred years’ experience with the material Lignostone® that is likewise used in high-voltage transformers.

Sales Manager Rainer Sanders sounds convinced: “The first measurements with the Phenolic-resin-glued variant Trafoboard HD-PH have run very promisingly. They indicate that we can come up with excellent electrical resistances that are on a par with the top product on the market”. Röchling has been working closely with the Osnabrück University for Applied Science in developing Trafoboard. The aim is to present this new material to select manufacturers of transformers, after successful testing in the university’s high-voltage laboratory to obtain the necessary special authorization also for application in high-voltage direct current transmission systems (HVDC).

HVDC transmission with high requirements

The quota of alternative energies in the overall energy mix is growing disproportionately high. Frequently, however, energy generation occurs far away from the consumers of the electricity. Windparks, in particular, that are installed with large wind power stations with over 5 Mega-watt (MW) output off-shore, which is to say far out to sea from the coast, require low-loss transport of the generated electricity over very long distances.

From the electrotechnical point of view, this requirement can be met with HVDC (high-voltage direct current transmission) technology. Here, the alternating current is converted into direct current for transport and reconverted back to alternating current at the end of the line. Special alternating current transformers and converter plants are needed for this.

These transformers that are implemented directly for long-distance line transmission have, for example, voltages of 500 kV, 765 kV, 800 kV (Kilovolt) or even higher in future. The very high voltages and the concomitant high electrical fields of HVDC transformers in the highest performance range require very homogeneous and very pure cellulose base materials. They are glued preferably in thicknesses of 3, 4 or 5 mm, with casein, polyester or with Phenolic resin to any sheet thickness desired. The product Trafoboard that is new for Röchling rounds off the Lignostone® qualities, which have been successfully applied for decades, for maximum voltage ranges.