Insulating parts from Röchling riding

At the end of 2009, the first Velaro bullet trains will be travelling between Moscow and St. Petersburg. Insulating parts made of Lignostone® and Durostone® from Röchling Engineering Plastics will ride along in the transformers of the rapid trains.

The Rail Operators of the Russian Railway AG (RZD) and Siemens signed an agreement for supplying eight bullet trains on the platform of Velaro RUS in May 2006. Velaro is a registered trademark of Siemens AG for a complete product family of high-speed trains. At the beginning of 2008, the first coach was assembled in Krefeld, Germany; in November last year the first complete multi-system train headed for Russia.

The Velaro RUS, with the Russian designation "Peregrine falcon", runs on Russian broad gauge.

The track gauge of Russian railways is 1,520 millimetres, in contrast to the track gauge in Germany that amounts to a mere 1,435 millimetres. This is why the train must not only be provided with widened wheel housings, but must be adapted to the special climatic conditions - in other words, fitted out with a special ventilation and cooling system suitable for the rough climatic conditions.

"Peregrine falcon" heading forwards

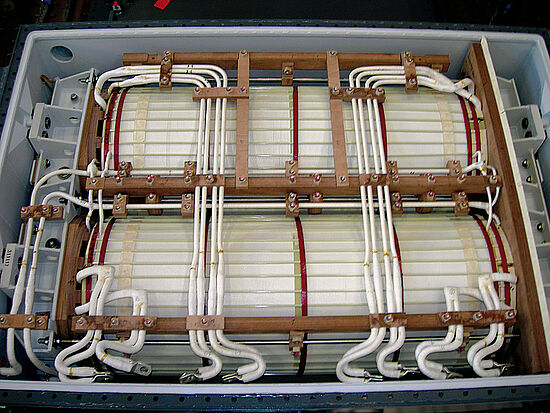

The Velaro RUS trains are 250 metres long and have room for 600 passengers in the ten coaches. As the train brake-rod linkage is attached underneath the coaches, more passengers can be accommodated in them than on usual trains of the same length. The "Peregrine falcon" will be travelling on the Moscow - St. Petersburg run at a speed of 250 km/h. Later on after the infrastructure has been extended, speeds of up to 330 km/h will be reached. In the "Peregrine falcon's" train set the transformers built by Siemens Energy Sector in Nuremberg will be doing their service. They transform the supply voltage of the contact overhead traction line from 25 kV to 1.55 kV. The insulating parts used in the transformers made of Lignostone® and Duro-stone® come from Röchling Engineering Plastics in Haren. Röchling delivered Lignostone® insulating components for a traction transformer in 1999 for the first time that was intended for a Russian railway train.