Complex Assembly of A Trocar With Metal Blade

A customer in the field of ophthalmology required a trocar assembly used in retinal surgery. This is a combination of a sharp metal blade with an over-molded handle (trocar) used to create an incision in the eye. Placed over the blade is a titanium hub and cannula with a silicone valve assembled onto the hub (valved cannula).

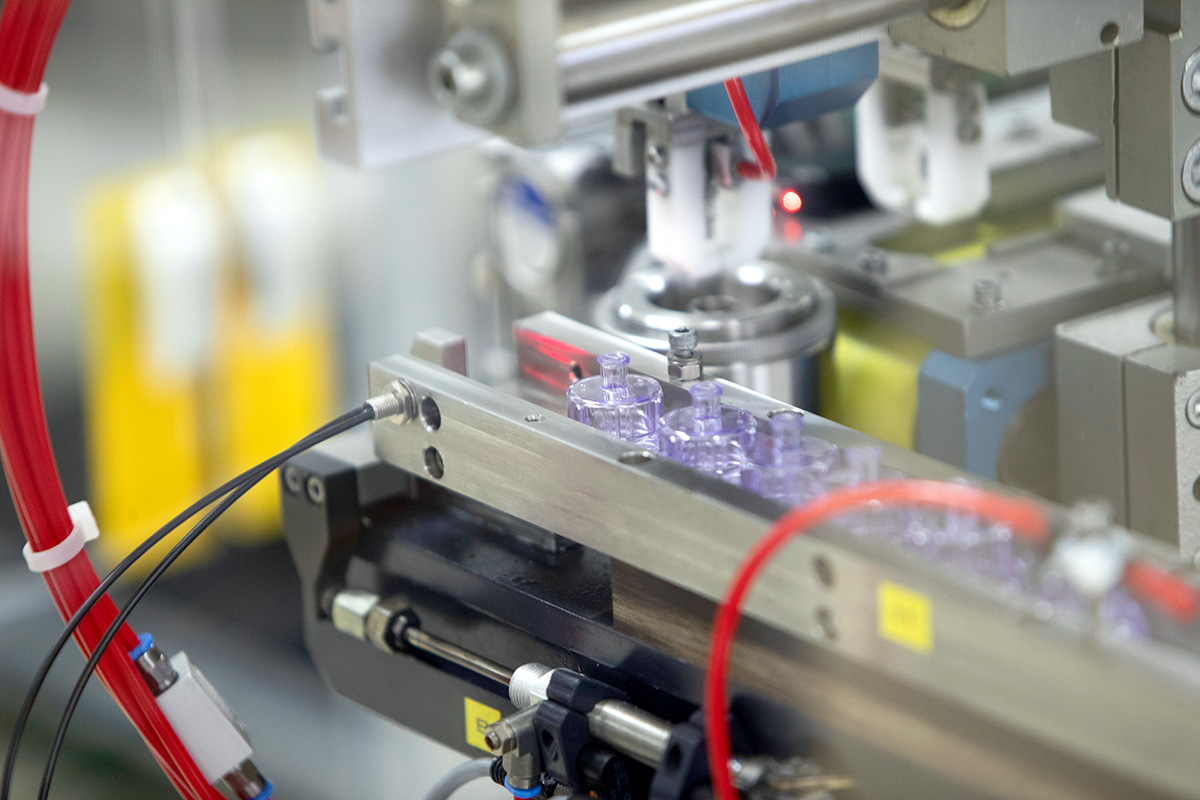

The assembly of the valved cannula onto the trocar requires a very careful assembly process, so as not to damage the silicone valve, which is used to allow introduction of instruments into the eye, while also preventing leakage of fluid from the eye.

There are different gauge sizes of blades due to surgeon preference and patient profiles and the customer required multiple packaging configurations that may contain a variety of other molded parts and assemblies

Our Solution: Metal and Plastic Processing from a Single Source

For this surgical instrument, we were able to combine our capabilties in metal and plastics processing.

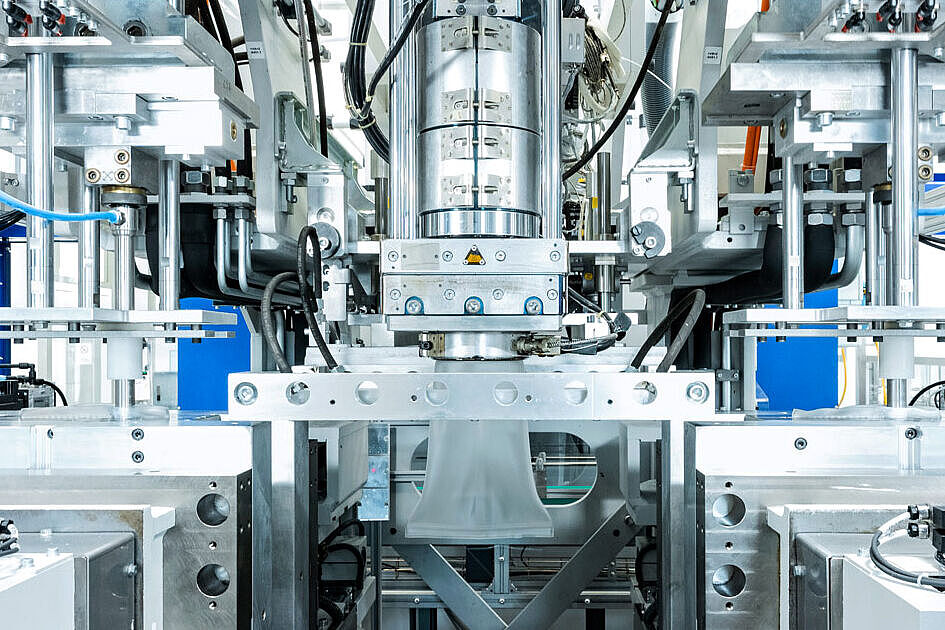

We utilize metal grinding processes for forming the metal blade in three different gauge sizes. The formed blades are then transferred to our injection molding facility where we have a single mold designed with removable inserts to accommodate the molding of each gauge size.

Röchling Medical manages the supply chain of additional components, such as silicone valves and cannulas. These components are very small, only milimeters in length, and are manually assembled together into the valved cannula assembly.

The valved cannula is carefully assembled onto the blade under a microscope so as not to damage the silicone valve. Damage to the valve could lead to a critical leakage defect.

The products are packaged in thermoformed clamshell trays along with an infusion set and plug blocks as a complete kit ready-to-use for the surgeon.

We are constantly optimizing production and output for this product, for example by automating process steps, which also leads to benefits in terms of quality consistency.

Expertise for the Manufacture of Complete Medical Devices

As a contract manufacturer combining capabilties in metal and plastics processing, Röchling Medical is able to act as a single source for this medical device, delivering it as a complete kit ready-to-use.

- Over 20 years of experience manufacturing surgical devices

- Expertise in metal and plastics processing in the clean room

- Complete contract manufacturing including supply chain management of purchased parts

- Constantly optimising processes to deliver cost and time-to-market advantages for our customers at consistently high quality

- Single source supplier

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical device and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our contract manufacturing capabilities for surgical instruments and medical devices, please contact our team.

We look forward to hearing from you.

Bill Ruth

Vice President - Sales & Marketing