In-house Capabilities for Efficiency & Flexibility

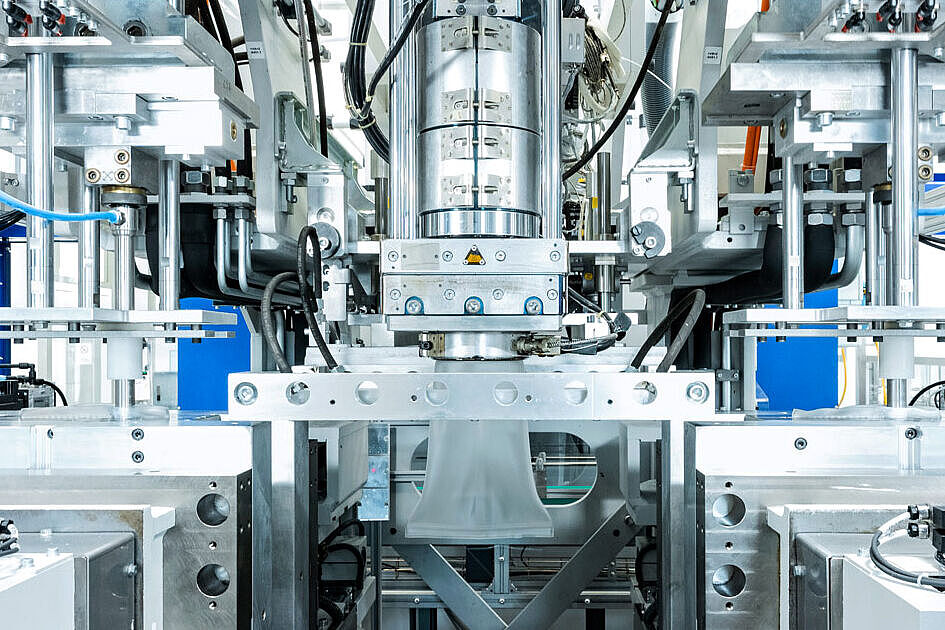

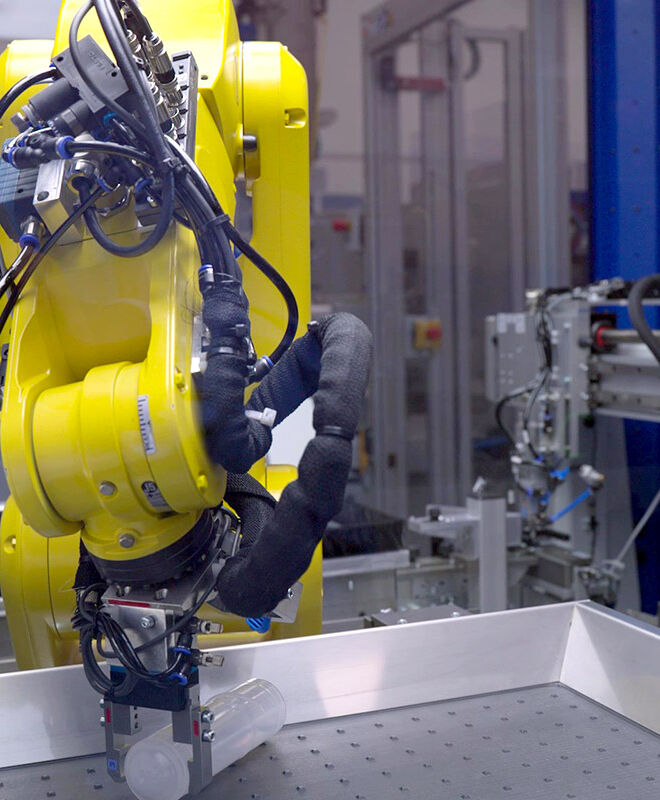

We specialize in designing and manufacturing tools and injection molds that are fully tailored to our customers’ needs. By keeping processes in-house, you work with us from start to finish. Our development, project management and production teams work in close collaboration with each other, leading to rapid reaction times and optimal maintenance schedules. In-house maintenance and storage of tools guarantee high production availability at all times.

Full Range of Mold-Making Options

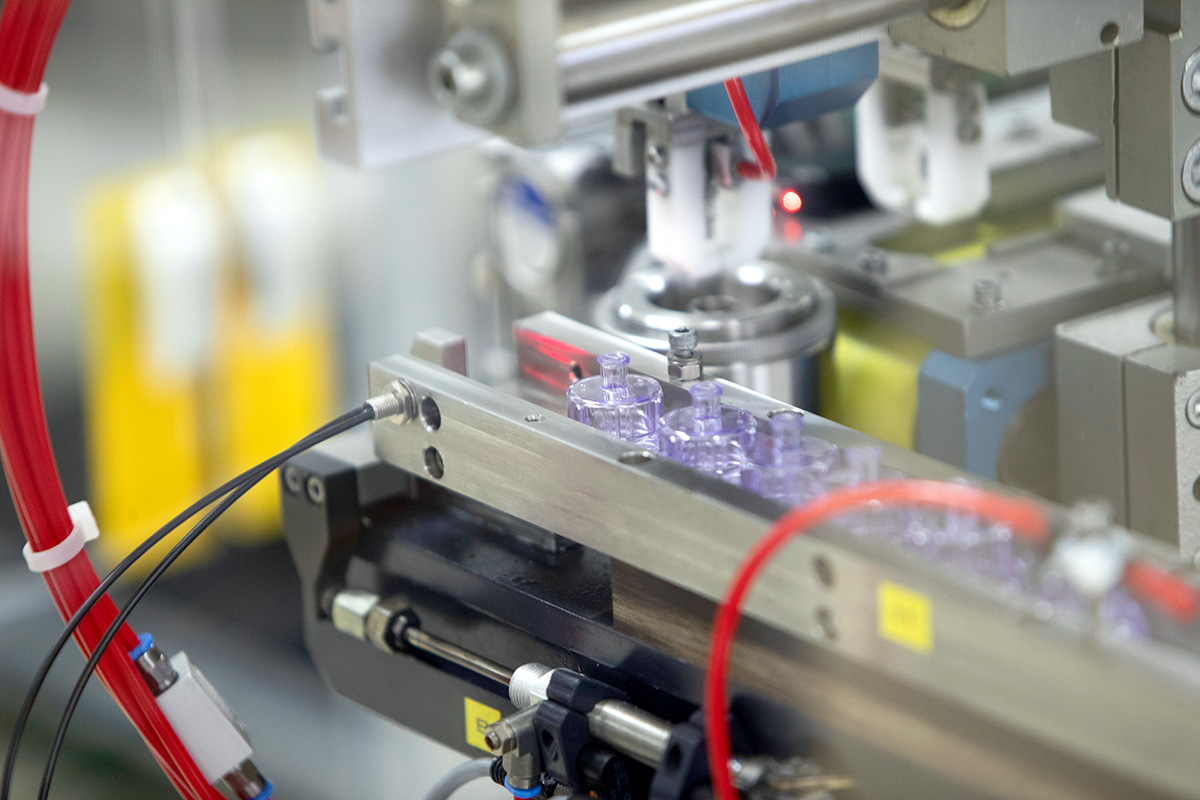

We offer the full range from prototype tools to bridge tools to tools for low and high volume series production.

Our technology competence encompasses high cavitation, full hot runner and stack molds, two-shot molding, over-molding, as well as complex mechanical, hydraulic and unscrewing actions. We are able to tailor injection molds to produce feature-rich, high-tolerance parts, complex geometries and high-gloss surfaces. We ensure that our molds perfectly match our client’s design specifications.

Röchling also fosters strong collaboration with external mold suppliers in Europe, Asia and the US for larger projects or according to our client’s specifications.

State-of–The Art Expertise and Equipment

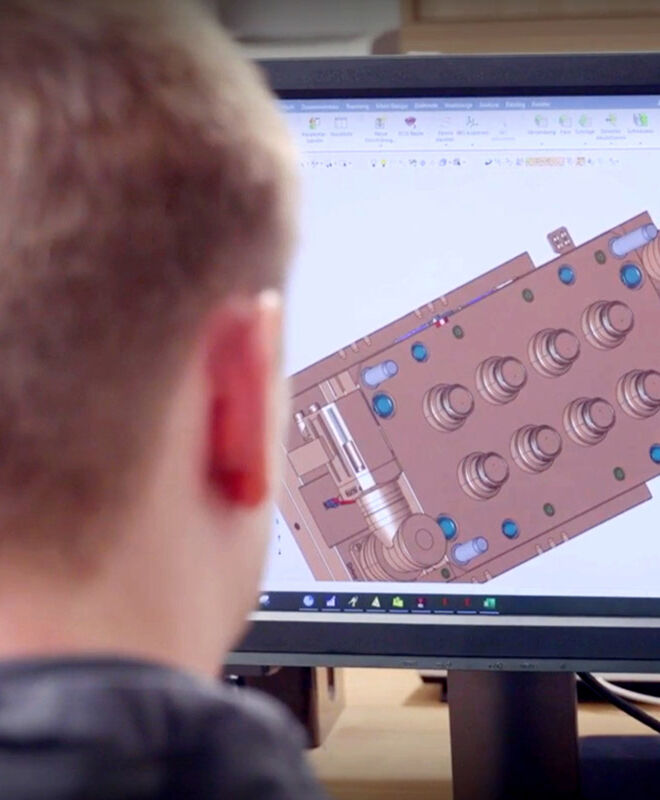

As a one-stop shop, we take care of everything from concept and design of customized molds through manufacturing and testing under near-series conditions to maintanance and servicing.

Our tooling centers are home to 3-axis and 5-axis CNC milling machines and state-of-the-art turning, sinking, eroding and grinding equipment. We use 3D printing and hybrid technologies for mold inserts. Our experts use analyses & simulations to optimize and overhaul tool designs for perfect precision and process quality.

All our services are based around meeting our customers’ exact requirements, enabling us to ensure optimum tool quality, stable manufacturing processes and high-quality output at all times.

Competences at the Following Locations

Case Studies

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

Patient-Centric Pharmaceutical Packaging Design

Optimizing a Complex Class 3 Medical Device

Innovative Plastic Protectors for Glass Injection Vials

Custom Automation Concepts

Design for Manufacturability

Automated Quality Control

Metal and Plastic Processing from a Single Source

Medical Device Contract Manufacturing

A Single Use Medical Device Designed for Sustainability

Simulations in Product Development

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our Tooling & Mold-Making Services, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing