Applications & Areas of Use

Röchling Medical develops and manufactures customized laboratory disposables such as petri dishes according to strict requirements of customers and applications.

Petri dishes are a staple of laboratory and diagnostics settings. As a single-use product, they are also known as cell culture plates due to their use in growing cultures of cells and bacteria as part of microbiological analysis, for example, in detecting the presence of MRSA or multi-drug-resistant microorganisms. They are also used in cleanrooms and isolator settings, where air monitoring to assess microorganism levels is crucial.

Product Features Overview

Our petri dishes are manufactured in strict compliance with our customers' requirements.

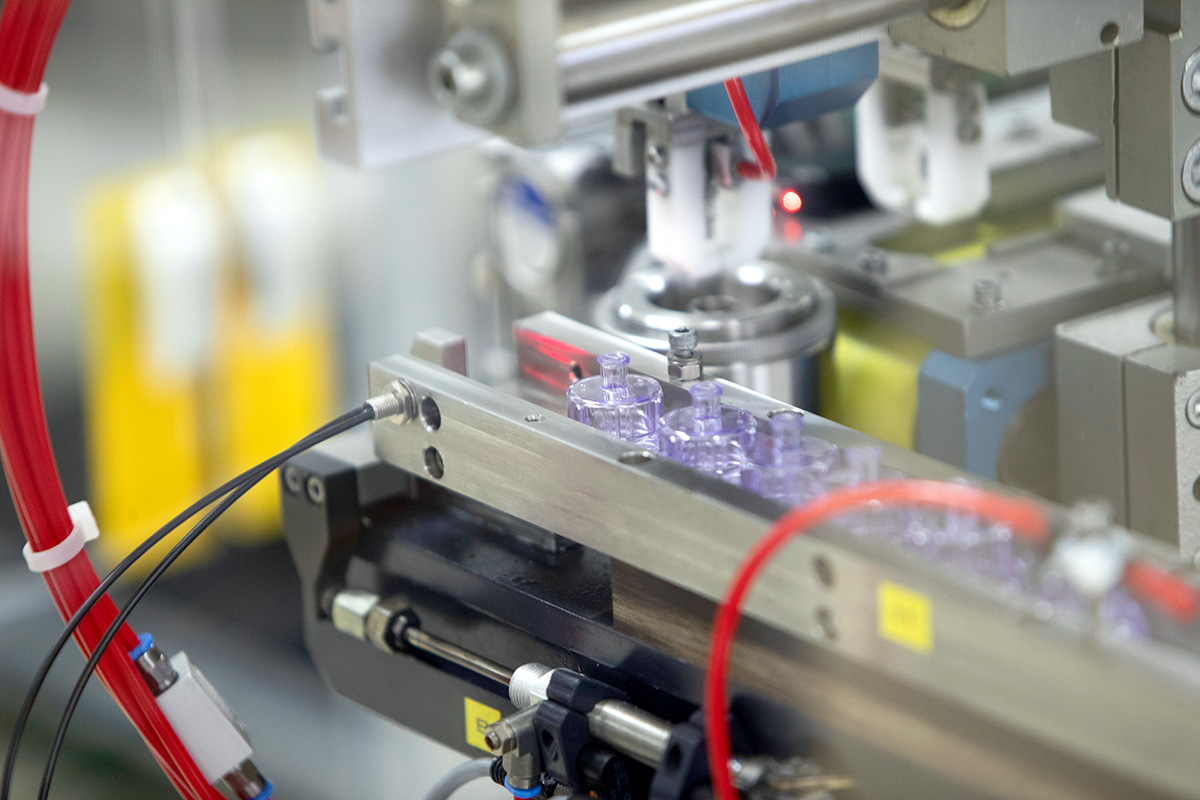

As an experienced partner for the development and manufacturing of solutions for medical technology, pharmaceuticals and diagnostics, we developed a tailored design for the two components, the bottom shell and top shell, which can be interlocked to protect the contents when in use. When manufacturing our petri dishes under cleanroom conditions, we comply with the strictest surface and material requirements and application-specific needs, to ensure flawless quality and usage.

- Contact surface is crystal clear for excellent visibility

- All petri dishes are produced under cleanroom conditions

- Locking lugs create a perfect seal between the bottom and top shell

- There are no injection points on the surface of the petri dish

- Petri dishes are delivered in safe, airtight packaging

Our Expertise

Automation Specialists

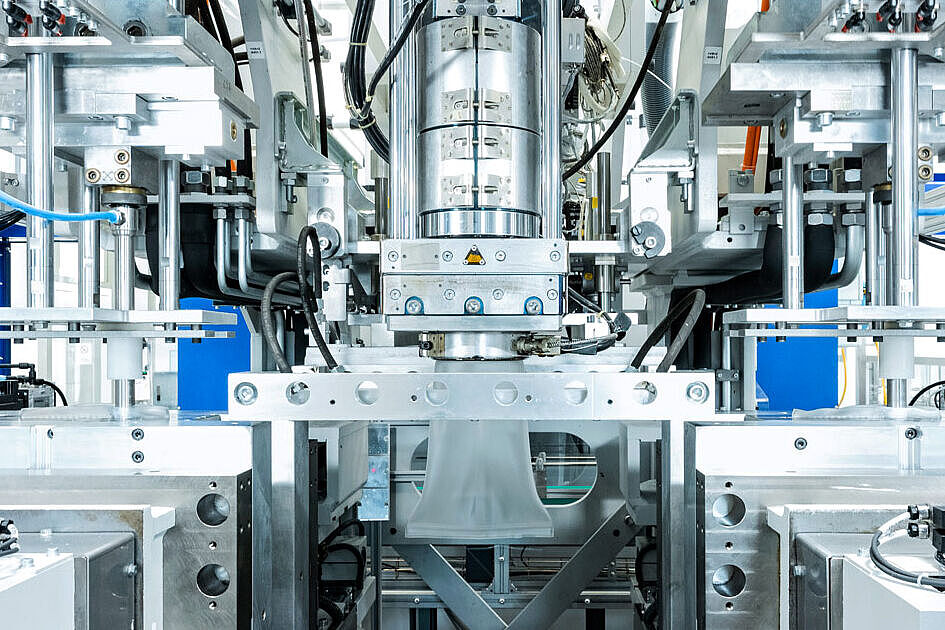

As your partner for the production of petri dishes for use in laboratories and diagnostics, Röchling Medical takes care of everything from prototyping to series production, entirely according to your requirements. We offer fully automated production with stack molds/molding surfaces in a 4+4 arrangement to increase output and reduce cycle time to a few seconds. Our petri dishes are manufactured under sterile ISO 8 cleanroom conditions, automatically sorted by cavity and hermetically packed. Due to the intelligent production techniques, they are optically and functionally flawless.

Custom Production

We design and produce all petri dishes in house under cleanroom conditions according to your exact specifications—from prototyping to serial production.

Optically Perfect Results

Thanks to our production techniques, the petri dishes are optically perfect, with no flaws or gating points on the surface of either the bottom shell or top shell.

Rapid Cycle Times

With fully automated in-house production using 4 + 4 stack molds, our petri dish assembly process has a cycle time of a few seconds for optimal efficiency.

Automated Safe Packaging

The packaging of our petri dishes in welded tubular bags with tight seals is fully automated and sorted by cavity directly after production.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for diagnostics and customized design options, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing