Application & Areas of Use

With decades of experience, we are partners with renowned customers when it comes to co-developing and manufacturing components for oxygenators. In an oxygenator, blood is enriched with oxygen and carbon dioxide is removed from it. The single-use component of the heart-lung machine is used to maintain gas exchange in cardiac surgery and for the treatment of acute respiratory failure in intensive care medicine. In this process, an oxygenator temporarily replaces the lung function.

Product Features Overview

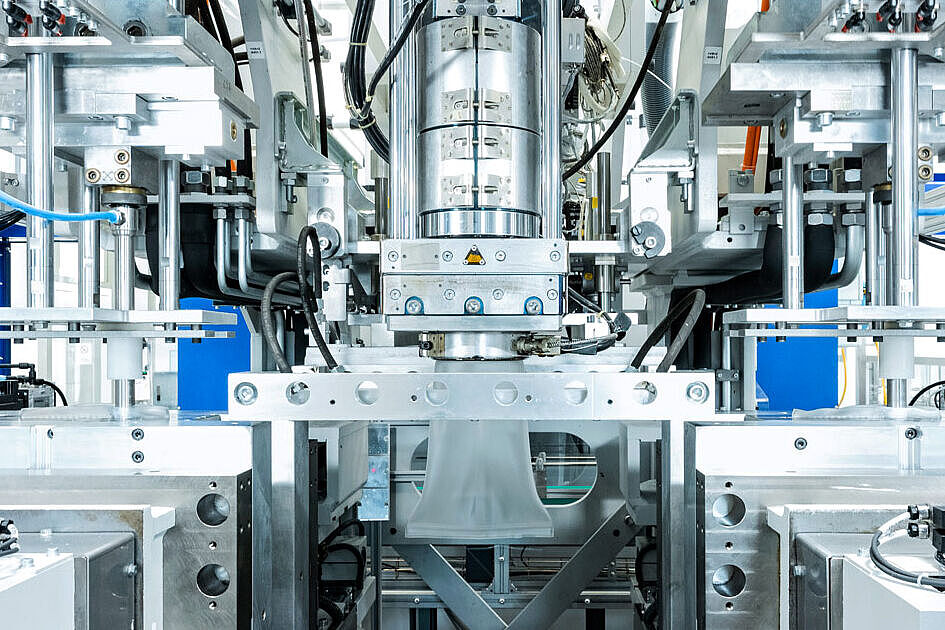

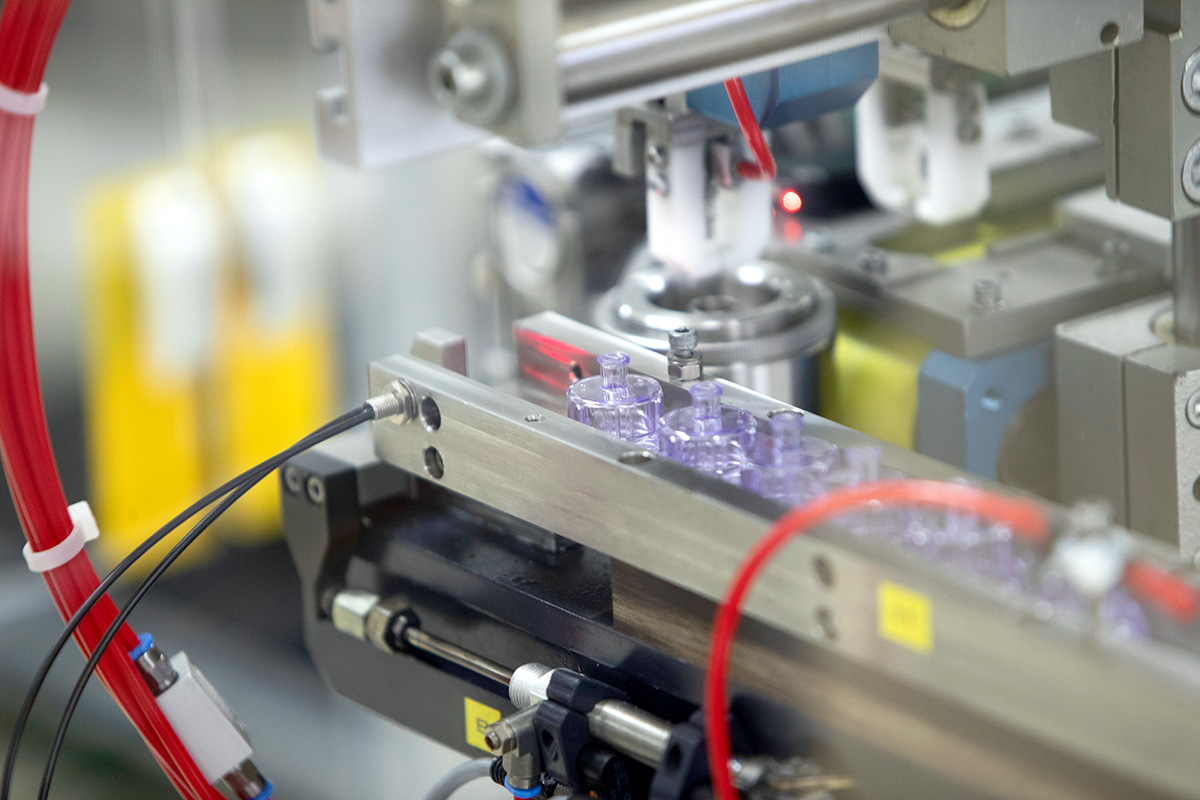

The individual oxygenator parts manufactured by Röchling Medical under controlled cleanroom conditions are assembled with other components to form a highly functional end product for a crucial medical intervention. For this reason, the specific properties of the individual highly complex components (e.g., highly polished or crystal-clear surfaces) are crucial, as are the assembly joining processes, including external assembly. For further processing, the precision of fit and tightness, as well as that of laser and mirror welding, must be ensured.

- Guaranteed accuracy of fit and tightness

- Precision design

- High-quality, highly polished, crystal clear components

Our Expertise

Precision in Design

As experts in the development and manufacture of plastic solutions, we cover the entire value chain from the initial idea to the completion of the individual components or assemblies. Thanks to our high-precision and customized component and mold designs, we produce components that meet the most demanding criteria for functionality and further processability. Our manufacturing process flexibility means that we can offer oxygenators in different color schemes and dimensions, with or without filters.

Sophisticated, Economic solutions

We follow the principles of design for manufacturability (DFM) to refine and optimize our design process, resulting in components of outstanding quality and reproducible costs.

Experts in Plastic Processing

We specialize in plastic and injection-molded design, and perform ultrasonic, mirror and laser welding processes with the highest precision.

Software-Based Design Simulations

We use the latest plastic injection molding simulation software to perform detailed simulations of injection molding processes and optimize our product designs.

Controlled Cleanroom Production

All parts are manufactured under particle-free and low-germ cleanroom conditions and are seamlessly controlled. Special packaging solutions ensure that the parts are delivered with optimal protection.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our medical device solutions, please contact our team.

We look forward to hearing from you.

Your Contact

Thierry Arnaud

Vice President - Sales & Marketing Europe