Application & Area of Use

Endoscopy is a critical part of minimally invasive surgery, involving insertion of a tube directly into the body to view specific internal organs or tissues.

Röchling Medical has specialized in the production of multilayer tubing reinforced with stainless steel or polyester braid for use in disposable endoscopes for leading manufacturers in the field.

The field of application calls for high flexibility, torsional stiffness, kink resistance and - depending on the tube´s usage - an extremely thin outer wall.

Product Features Overview

Multilayer shafts for use in endoscopes are subject to a wide range of requirements.

Our shafts allow for an extremely small bending radius, while providing maximum stability in terms of torsion, buckling and pressure – with a rotation of up to 360°. We also guarantee a homogeneous surface and clean-cut edges for complete safety during medical procedures. The multilayer structure of the shaft calls for each individual layer to bond together and fully enclose the braiding to prevent delamination and eliminate the risk of collapse, even when using vacuum suction.

- Kink-resistant even with 360-degree rotation

- Multilayer design with minimal wall thickness

- Large inner diameter for insertion of Bowden cables, working channel, etc.

- Wide use in fields such as urology, gastroenterology, anesthesia, surgery, oncology, etc.

Our Expertise

Medical Tubing Specialists

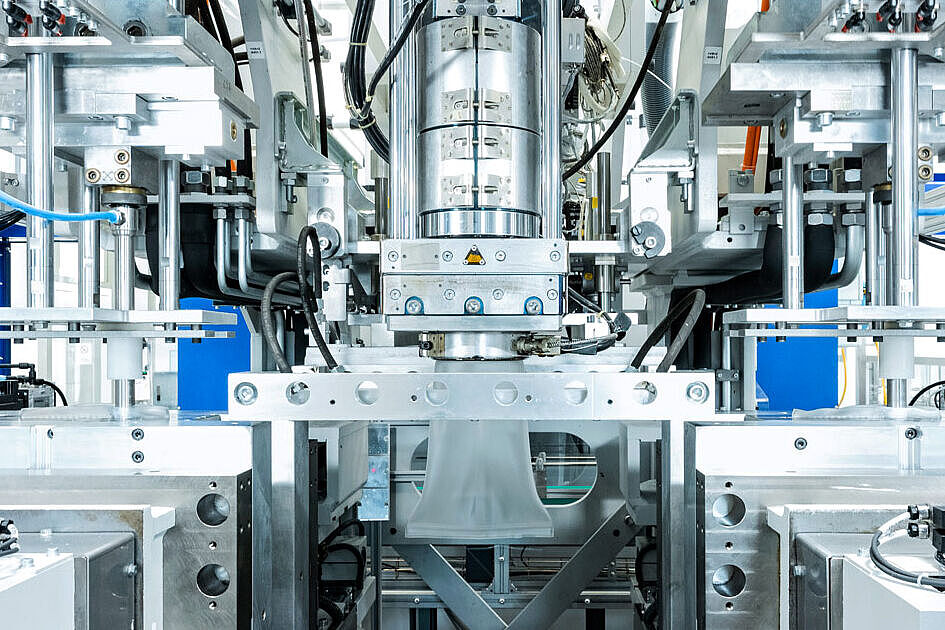

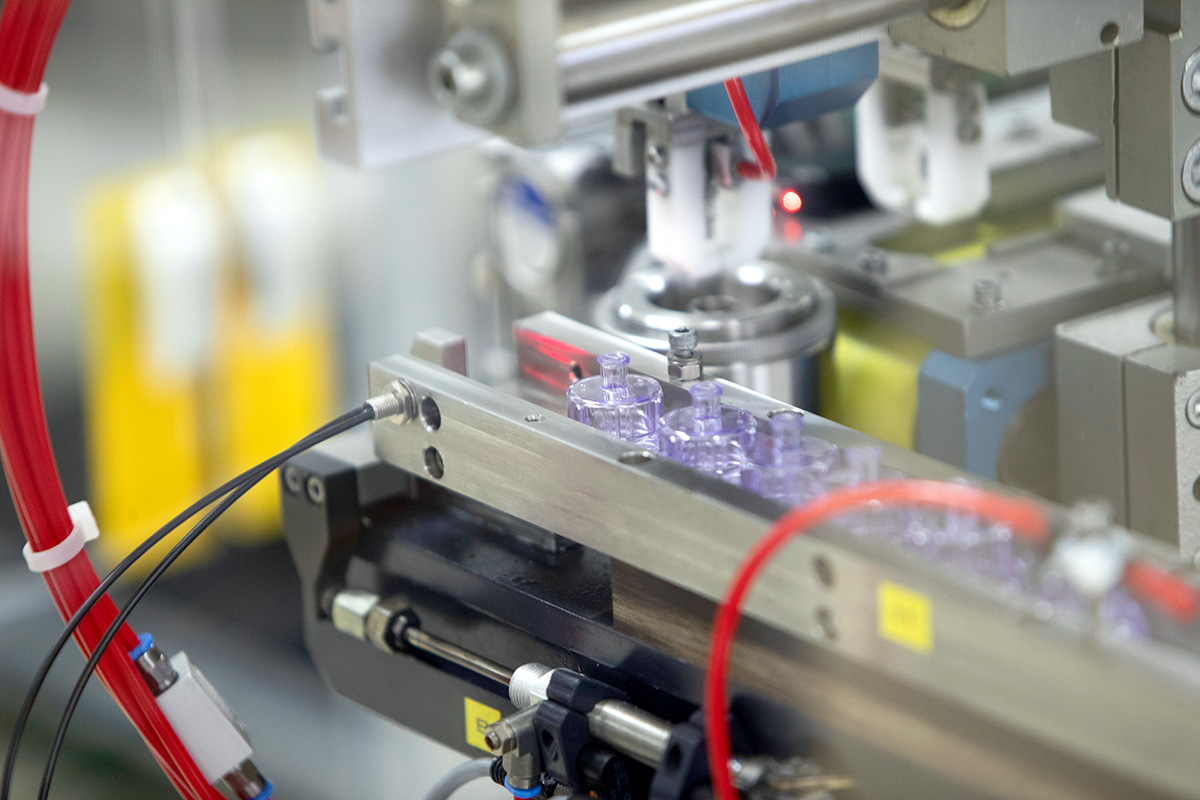

To achieve the required product properties, we combined various plastics with a specially developed braiding material in a multi-stage manufacturing process that adheres to tight tolerances. Under controlled clean room conditions, the different layers are produced via extrusion, assembled and packaged by our experts, resulting in a robust product with an available outer diameter of 2-9 mm. Considering materials, braid types, dimensions and tolerances, this project is a prime example of our development expertise.

Cleanroom Competence

As a specialist in manufacturing high-quality solutions for medical applications, we understand how to design clean room concepts that meet exceptionally high requirements.

Material Expertise

To achieve the ideal material properties in interaction, we specialize in the intelligent selection and combination of different materials.

Full Assembly & Packaging

We are experts in the extrusion, assembly and packaging of products under cleanroom conditions according to ISO 8 standards, thus enabling their use in a range of strictly controlled medical settings.

Automated Quality Inspection

All of our production processes for multilayer shafts are automated, allowing for 100% in-line monitoring of each layer to guarantee dimensional accuracy and consistent product quality.

Manufacturing at the Following Locations

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our expertise in medical tubing and cleanroom extrusion, please contact our team.

We look forward to hearing from you.

Your Contact

Thierry Arnaud

Vice President - Sales & Marketing Europe