After a mere two years on the market, Trafoboard® already enjoys an outstanding reputation in the industry and follows up on the over 90-year success story of Lignostone® Tranformerwood®.

For highest requirements on the electrical properties

is an insulation material for the highest requirements made on the electrical properties. In the development phase, Röchling was involved in close co-operation with the University for Applied Sciences Osnabrück.

Two Pressboard-grades

Röchling offers this material in two different variants:

Trafoboard® HD-PG (polyester-glued) is a tightly compressed, laminated press-board bonded with polyester resin comprising homogeneous, chemically very pure cellulose.

Röchling is initially offering this insulation material in the standard size 2,050 x 1,050 mm and in thicknesses of 10 to 120 mm. Machined components over 120 mm thick can also be supplied on request.

Trafoboard® HD-PH (phenolic-glued), in which a special phenolic resin glue is used, offers excellent electrical strength, which is equal to the top product on the market. For this glueing technology, Röchling has practically one hundred years’ experience with the Lignostone® material that is likewise used in high-voltage transformers.

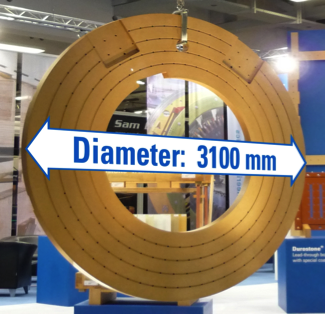

Röchling supplies platforms made of this material in dimensions up to 4,150 x 2,150 mm as well as rings up to 3,100 mm in diameter.

Corporate portrait

The globally operating Röchling Group stands for competence in plastics with more than 6,000 on the payroll at 55 locations in 20 countries. With its two business units "High-Performance Plastics" and "Automotive Plastics", the company focusses on processing high-grade plastics to fabricate semi-finished products, parts and systems for a host of industrial applications.

Röchling stands for innovative products and cutting-edge process technology in processing technical Plastics.