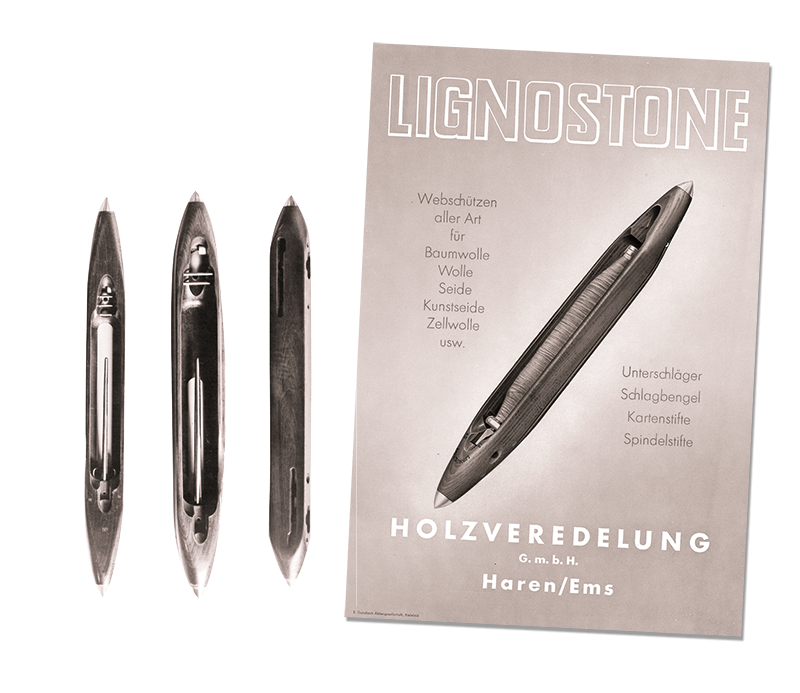

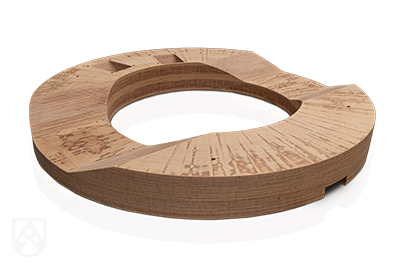

Lignostone® - Laminated densified wood

Buy from the inventor and global market leader of laminated densified wood - more than 100 years of experience

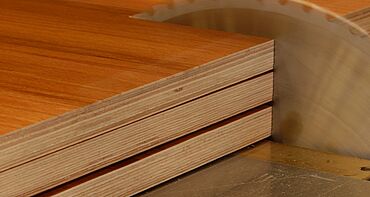

Lignostone® - laminated densified wood directly from the inventor. Consisting of veneers of the common beech (Fagus sylvatica) bonded using curable synthetic resins in conjunction with pressure and heat. More than 100 years of experience. For exceptional and scientifically proven mechanical and isolating properties.

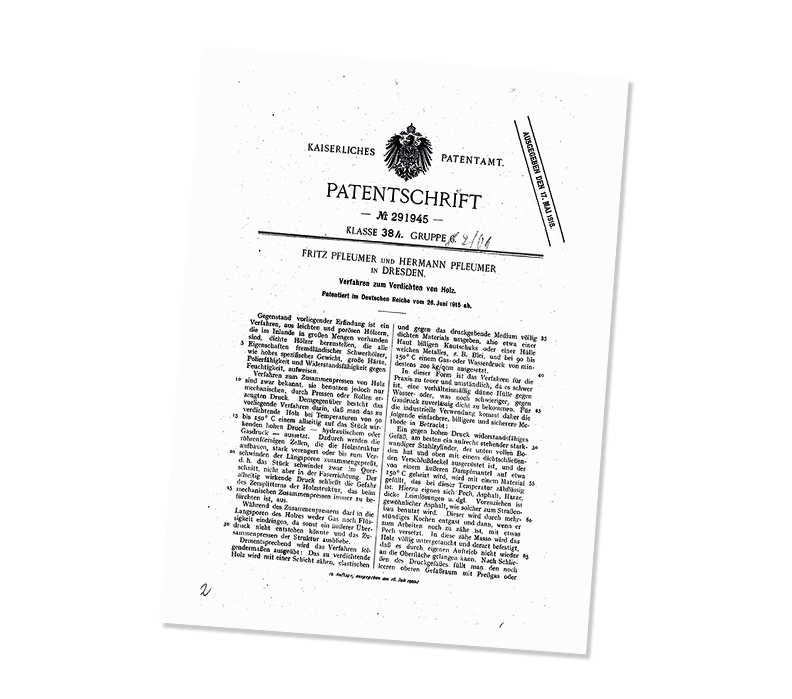

Inventor and market leader

We are the inventor of laminated densified wood. With more 100 years of experience in the manufacture and processing of products made of laminated densified wood, our knowledge of the material, its potential and its performance is second to none.

Market leader

Röchling is the world's largest manufacturer of laminated densified wood and the market leader for insulation components made of laminated densified wood in electrical engineering and thermal insulation for the low temperature range in shipbuilding.

State-of-the-art production facilities

We manufacture Lignostone® on state-of-the-art production facilities and the world's largest presses at a format of up to 3560 x 4360mm.

Made in Germany

We have been manufacturing sheets rings and finished parts of Lignostone® laminated densified wood at our site in Haren/Germany for more than 80 years.

Properties - Lignostone® - Laminated densified wood

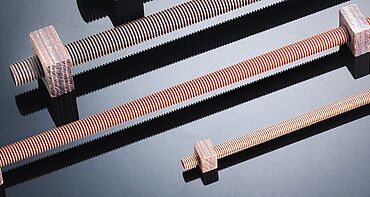

- withstands high mechanical loading

- good electrical insulation

- low thermal conductivity

- low- and high-temperature resistance

- resistance to abrasion and wear

- low coefficient of sliding friction

- low specific weight

- very good oil absorption

We are ISO 9001:2015 certified

Our Quality Management System has been ISO 9001:2015 certified and thus ensures our continuously high quality of Lignostone® laminated densified wood.

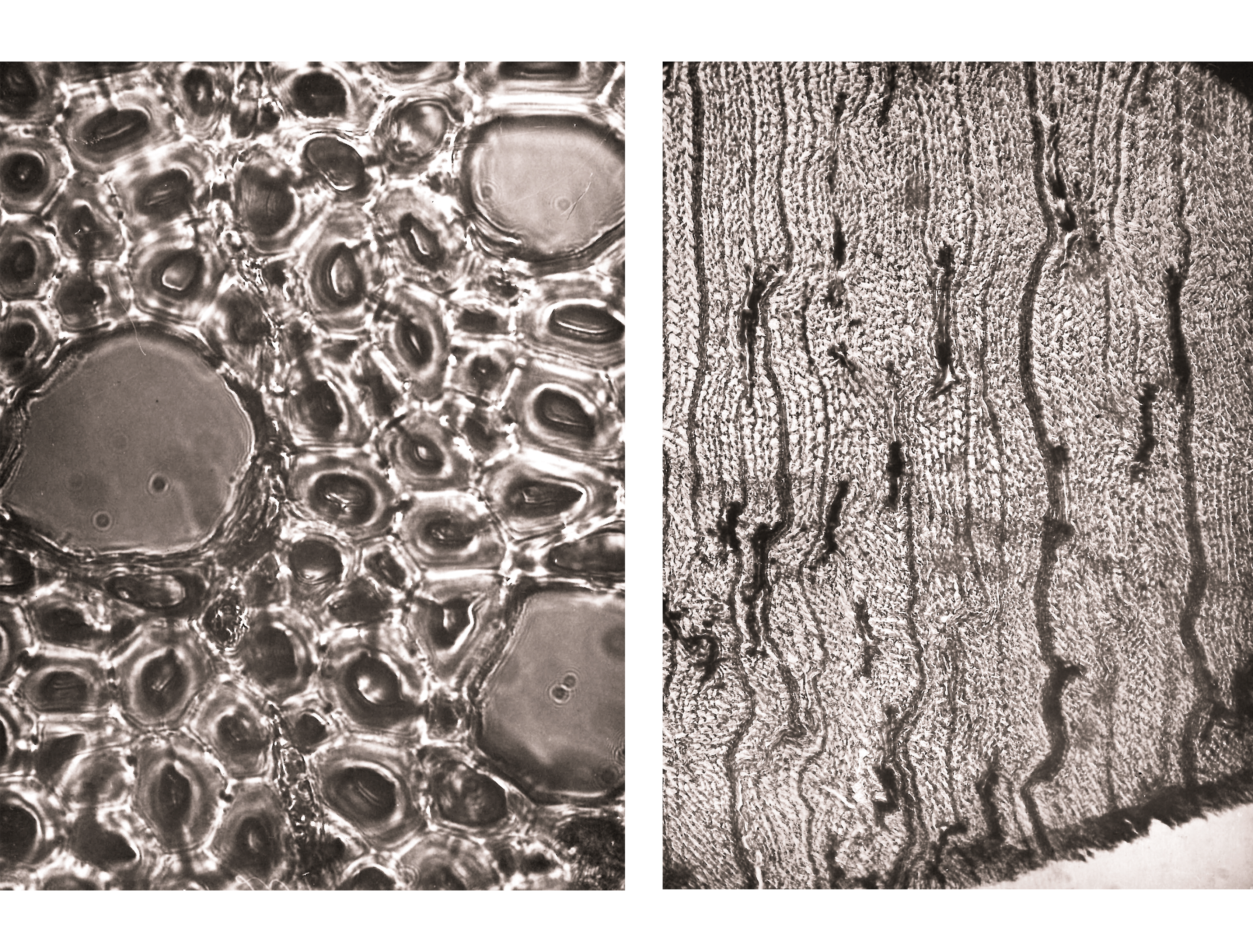

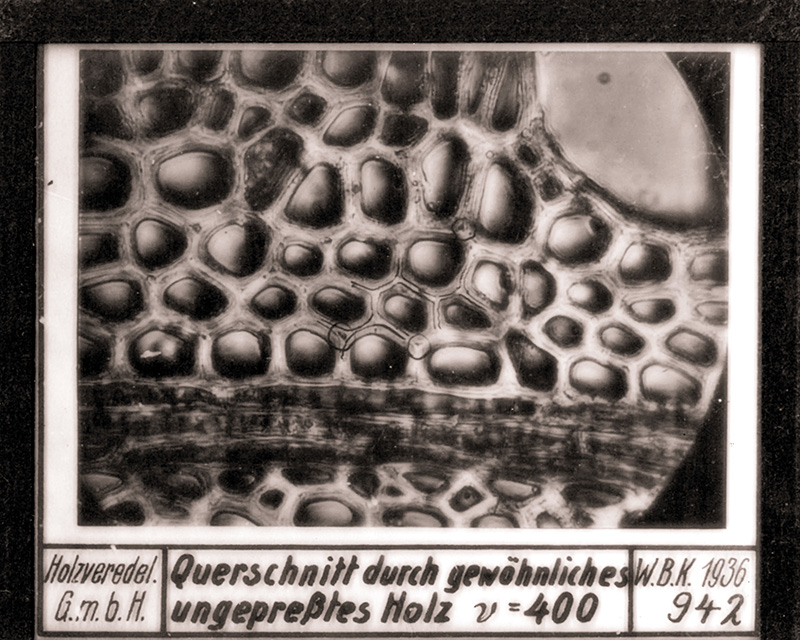

What is special about Lignostone® laminated densified wood?

For Lignostone® selected red beech veneers from highest quality are used. The peeled veneers used for Lignostone® are subject to stringent quality specifications and come from sustainable forest management.

Thanks to the excellent conditions in Western Europe for growing beech within a period of around 120 years, top grades of this product from logs of suitable length felled in the right locations offer extremely

good homogeneity that enables them to withstand the extremely high electric stresses. In addition to its electrical strengths, due to its intact capillaries with continuous load-bearing fibres this material offers unsurpassed mechanical strength values, which depend on the direction of lamination and the densification.

Applications

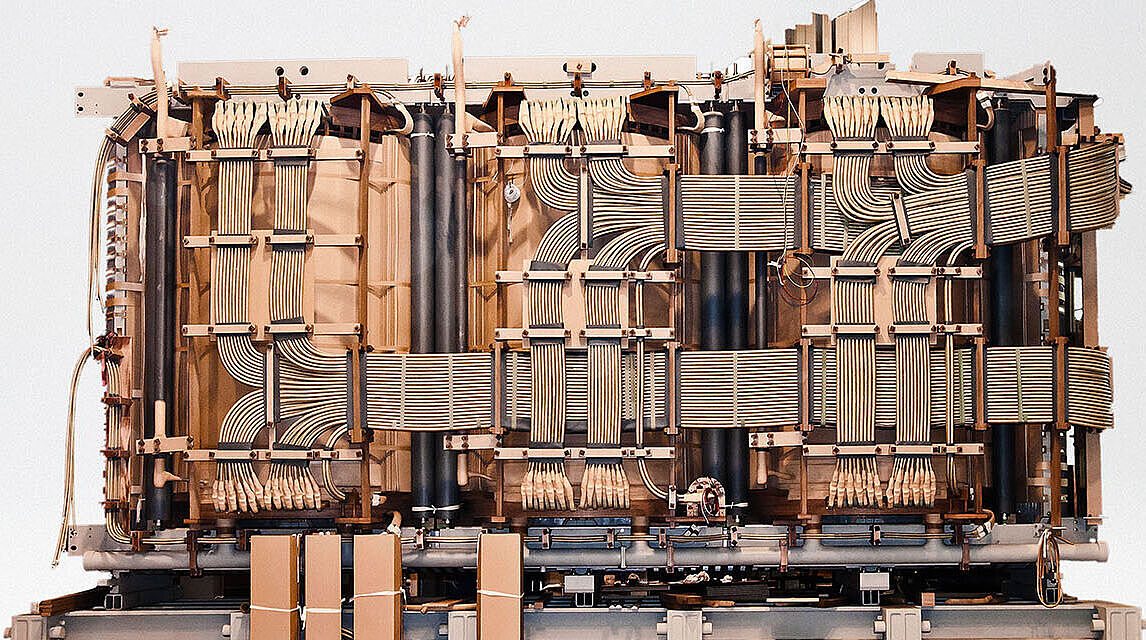

Due to its special material properties, Lignostone® is mainly used as insulation material in transformer construction and as thermal insulation for tank supports in LNG and LPG vessels.

Transformer construction

Under the brand name Lignostone® Transformerwood® we offer you a laminated densified wood according to IEC 61061 for the construction of transformers.

More information about Lignostone® Transformerwood® for transformers

Cryogenic insulation - LNG

Under the brand name Lignostone® cryogenic our laminated densified wood is used world wide as material for tank supports in LNG and LPG vessels and for fuel tanks in LNG engines. More information about Lignostone® cryogenic for:

Lignostone® conserves valuable resources

We only purchase rotary cut veneers for manufacturing Lignostone® from suppliers who are certified in accordance with the regulations of the Forest Stewardship Council (FSC) FSC® product chain. The Forest Stewardship Council (FSC) based in Bonn is an international non-profit organisation that promotes the environmentally friendly and economically viable management of forests. For this purpose, it has developed standards based on which companies can be certified.

FSC® chain of custody certification ensures that the products of certified companies are made from responsibly sourced raw materials. For this purpose, companies have to streamline their processes and procedures in such a way that the traceability of the raw materials used is ensured and that statements can be made regarding the raw materials used in the product.