- More and More Distinctive Global Positioning

- Sales Increased More than 50 Percent in the Last Four Years

- Highly Innovative in All Global Economic Centers

- Outstanding Start in the Current Fiscal Year

Mannheim, Germany, June 25, 2014 The Röchling Group got off to a very good start in 2014. In the first quarter, it achieved a 10.6 percent increase in sales to EUR 338.1 million. Incoming orders rose by 10.8 percent to EUR 350.2 million. “Success is attributable to both divisions,” reported Georg Duffner, President and CEO. “Both the High-Performance Plastics and Automotive Plastics divisions achieved record sales.”

The 2013 fiscal year was successful for the Röchling Group despite economic weakness at the beginning of the year. The world economy stabilized in the spring and revived markedly toward year’s end. A moderate recovery began in the eurozone and the USA. In Germany the gross domestic product increased by 0.4 percent from the previous year, while economic growth in the newly industrializing countries initially slowed before picking up again due to rising exports at the end of the year.

The Röchling Group increased Group sales in the 2013 fiscal year to a new record. It grew by 7.5 percent to EUR 1,282.5 million. “In the past four years, we increased our sales by more than 50 percent from EUR 0.8 billion to nearly EUR 1.3 billion,” Duffner said. “We recorded this growth in all global economic centers – particularly in Asia and America.”

Germany accounted for 34 percent of total sales, while 33 percent accrued to the rest of Europe. America and Asia achieved sales shares of 20 percent and 13 percent, respectively. The largest customer group is “automotive technology” with a sales share of 52 percent. The group “retail and machining” follows with 16 percent. Electrical and electronics industry (7 percent) is in third place. They are followed by these sectors: chemicals and environment (5 percent), mechanical engineering (5 percent), and medical technology (4 percent).

Incoming orders also reached a new record level. They rose by 8.3 percent to EUR 1,294.8 million. Investments were high again at EUR 82,9 million, but they fell short of the amount in 2012. They focused primarily on expanding worldwide production. “We reaped the rewards after record investments in 2011 and 2012,” said Marc Trube, Röchling CFO. The number of employees rose by 4.2 percent to 7,463 as of the end of 2013.

High-Performance Plastics Increases Sales by 7.4 Percent

In the High-Performance Plastics division, the Röchling Group achieved a 7.4 percent increase in sales to EUR 637.6 million. Also here incoming orders grew somewhat more strongly. They rose by 7.9 percent to EUR 648.7 million. The number of employees in-creased by 3.1 percent to 3,257, while investments of EUR 27.6 million remained 64.7 percent below the level in 2012. The largest portion accrued to the expansion of production at MAYWO Kunststoff GmbH (Bad Grönenbach-Thal), Röchling Engineering Plastics KG (Haren), and the new production site in Vadodara, India which opened at the beginning of this year. “Expanding the High-Performance Plastics division remains a pillar of our strategy,” emphasized Ludger Bartels, COO of Röchling.

In 2013, the division again produced a series of outstanding innovations. For example, Röchling is setting new standards for the production of complex components using 3D printing. By adopting selective laser sintering, the Company is in a position to manufacture complex plastic parts, which could previously not be produced with traditional CNC machining or injection molding. The new technology offers significant advantages regarding quality, mechanical strength, and reproducibility. Another important innovation was the development of two new materials for the optimal insulation of generators: the Group presented Duromag® EPF S13 and Durostone® EPC SL38 at the CWIEME 2013 trade show in Berlin.

Röchling developed a new spray protection flap for the logistics fleet of the United Parcel Service (UPS). Safe-Pass® Aero improves visibility and reduces fuel consumption. Another new development are “breakwaters” for large bakeries made from the high-performance material SUSTARIN® C FG. The thin plastic sheets lift up the slices of bread lying on conveyor belts. The pressure of the following slices of bread pushes them gently out of the intervals so that the sliced loaf is ready to be shrink-wrapped as a unit.

Röchling recorded a major success in medical technology. One of the world’s leading manufacturers of endoscopic technology now uses the Röchling material SUSTAPEEK MG black for camera housings and handles.

State-of-art Technology for Wind Turbines

Similarly, Röchling is one of the technology leaders in the area of renewable energy. Now sliding sheets made from the new material SUSTARIN® C GLD 350 ensure a faster and more precise orientation for the rotor blades of wind turbines. Thanks to their self-lubricating properties, the rotors move in the wind quickly, evenly, and with minimal resistance. Röchling improved safety in public transport with the development of the flame-retardant material SUSTAMID 6 FR. High temperature-resistant products made from this material include cable clamps as well as rods and flat bars for rolling stock, aircraft, and ships.

The High-Performance Plastics division strengthened its position in Japan with the establishment of the new subsidiary Röchling Engineering Plastics Japan Co., Ltd. (Yokohama).

Automotive Plastics Grows Primarily in Asia and North America

The performance of the business with Automotive Plastics was just as encouraging as with High-Performance Plastics. The division recorded a 7.7 percent increase in sales to EUR 645.2 million. Incoming orders rose by 8.7 percent to EUR 646.4 million.

In particular, the strong demand in Asia and North America was a growth driver. In Europe, the automotive sector, which was declining until mid-year, slowed down business. As was the case with High-Performance Plastics, investments were slightly lower this year. They fell by EUR 7.3 million or 11.8 percent to EUR 54.6 million. The largest investment share was dedicated to expanding production. Along with constructing new production plants, the Röchling Group focused on the reconstruction of plants in Wackersdorf, Germany; Araia, Spain; and Kunshan, China. The number of employees in the Automotive Plastics division increased by 198 from the previous year to 4,172.

Among the highlights of the past year was the opening of a new plant in Araia, Spain. By the end of 2013, 55 employees at the 16,500 square-meter plant produced primarily aerodynamically, thermally, and acoustically efficient controlled shutter systems, deflectors, and partition walls. In addition, wheel arch liners and center control panels belong to the range of components which are delivered from Araia to VW, Ford, and Daimler, among other customers. A complete plant relocation was on the agenda in Wackersdorf. Röchling Automotive moved from the innovation park there to the nearby industrial area. The 36,000 square-meter large property houses a production facility, including logistics and administrative services. Currently, a new plant is being occupied in Kunshan, China, which will be the future home of the Asia headquarters of Röchling Automotive. Kunshan is also the location of Röchling’s largest production hall worldwide.

One of the largest orders is for 100,000 3D blow molded pressure pipes for the Fiat Viaggio being manufactured in China. Beginning this August, the new luxury-class saloons from the Volkswagen Group will be fitted with underbody panels from Röchling Automotive. Röchling booked a large order for SCR tank systems for two models from Skoda and VW.

Röchling Suppresses Noise with Mercedes S Class Underbodies

Underbodies from Röchling Automotive help the Mercedes S Class perform more quietly and softly. Röchling technology is also aboard the new C class. Wheel arch liners have been delivered since the end of last year.

BMW just commissioned Röchling Automotive for several system developments for the purpose of further reducing exhaust and noise emissions, including the development of SCR systems. For its Chinese production, BMW ordered wheel arch liners, injection-molded parts for the underbody area, and a front wall package.

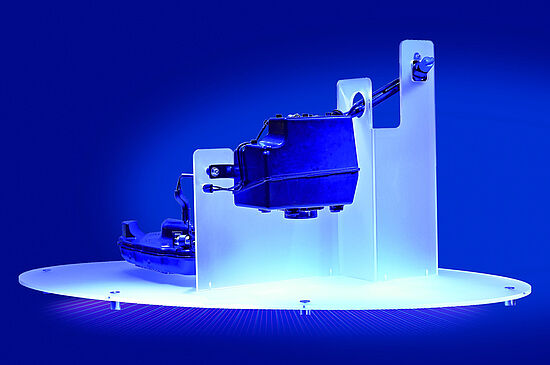

All-terrain vehicles from Jaguar Land Rover place the highest demands on quality and load capacity. Röchling delivers degas bottles for the all-terrain vehicles. Another large order for controllable air duct systems came from Nissan. Mazda also rides with Röchling: In June 2013, production of air flap control systems for the “Axela” and “Atenza” models was launched in Japan. Production takes place at “Starlite,” Röchling Automotive’s partner firm there.

Toyota decided in favor of Röchling as the future supplier of charge-air tubes, which are already being used in several models. Röchling is also demonstrating its lightweight expertise for the Italian truck manufacturer Iveco. Thanks to Röchling technology, 30,000 “Iveco Stralis” trucks are benefiting from weight savings of 250 percent by using plastic covers. A new “blow-by” cover, which consists of plastic polyamide instead of aluminum, is the decisive factor. Chang’an Ford, a joint venture of the respective American and Chinese automobile manufacturers Ford and Changan, ordered air flaps, deflectors, and windshield cowls produced by Röchling Automotive at the Chengdu, China site.

Numerous international awards document the technology leadership of the Röchling Group in many branches of plastics production. For example, the group in Livonia, a suburb of Detroit, once again received the coveted Innovation Award of the Society of Plastic

Engineers in the Powertrain category. The award was for an innovative flexible charge-air tube used in Audi engines of the A4 and A5 models, resulting in weight savings of 30 percent compared with the predecessor version. General Motors awarded another prestigious prize. Production quality at the Laives, Italy site was honored with the Supplier Quality Excellence Award.

For the full year of 2014, Duffner sees good opportunities to maintain growth and achieve additional records in various areas. “We have positioned ourselves well for the future with the right products for the right customers in the right markets,” the CEO said. “Along with our expertise in the plastics business, our ever more international orientation is decisive. The diversity of nationalities and cultures is among our most important strengths.”