+

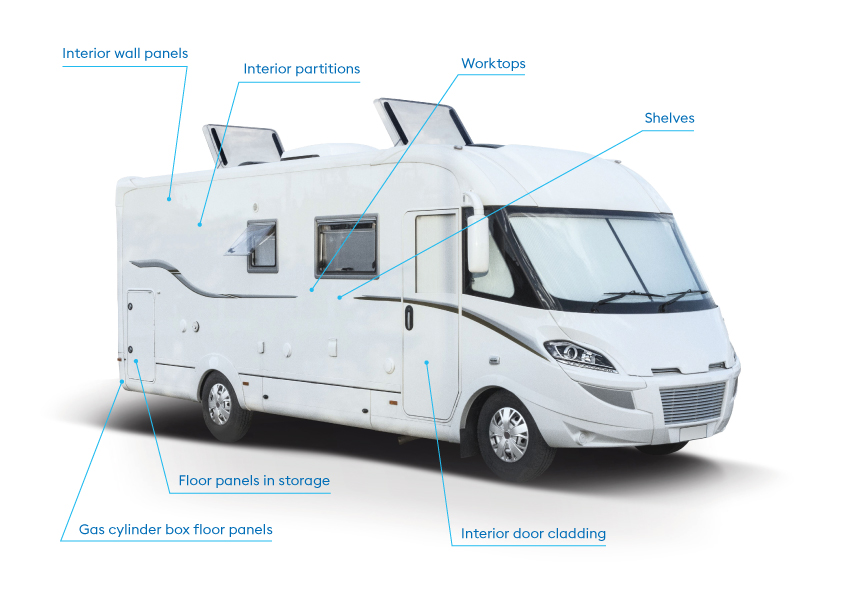

Foamlite® panels: Numerous possible applications in RVs, motor homes, caravans and camper vans

Camping is a lifestyle: Going on holiday without leaving your own four walls, spending evenings by the caravan enjoying the sunset or taking a flexible day trip – more and more people want to experience this. For optimum relaxation, manufacturers are constantly working to improve comfort, safety and efficiency. We support them in developing efficient, durable RVs, caravans and camper vans with lining/wall panels made from our lightweight material Foamlite®.

Foamlite® lining sheets

Foamlite® is a closed-pore foamed plastic that combines low weight with high mechanical stability. Foamlite® lightweight sheets:

Foamlite® lining sheets - Application areas

Manufacturers of motor homes, caravans and camper vans use Foamlite® lining panels to produce very light, robust and visually high-quality:

Vehicles:

Foamlite® sheets are available for cladding transport vehicles in many different formats, thicknesses, colours:

Surfaces in commercial vehicles must withstand high mechanical wear and tear in many areas over the long term. Tests in our in-house materials laboratory show that Foamlite® vehicle construction sheets have significantly higher abrasion resistance in comparison with tested conventional plywood (textured coated board) vehicle construction sheets.

Foamlite® has a "built-in" hinge. All that is required is a 90 degree milled V-notch. This means it is very easy to make doors with V-grooves, for example. This saves time in the manufacturing process and eliminates additional material costs for hinges, screws and rivets.