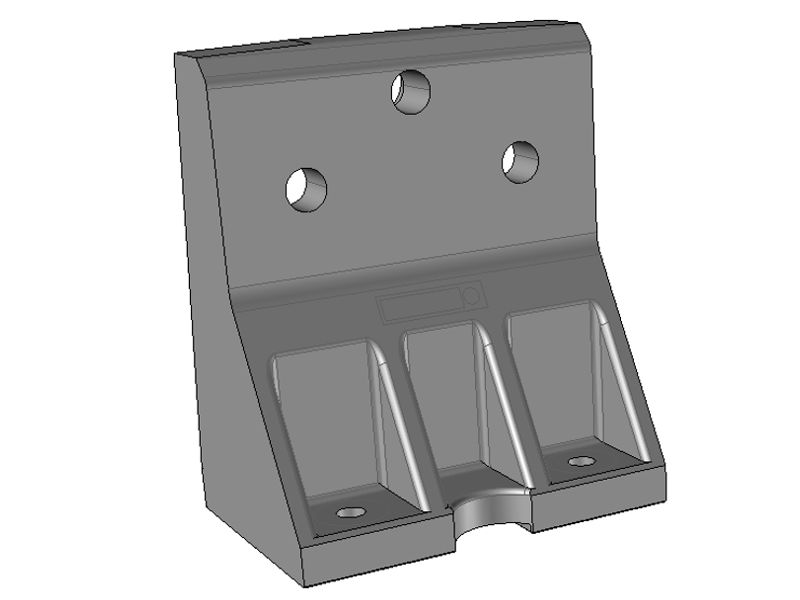

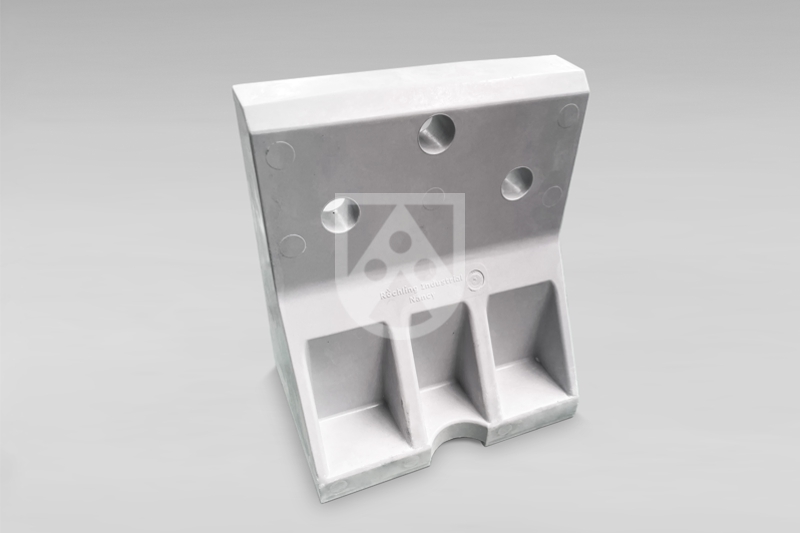

With modern presses and precise tools we produce the most varied FRP components and pressed parts from SMC and BMC-polyester products. In the SMC technique, a combination of resin and fibres is cured in a mould under pressure and heat. The production method enables time savings, high reproducibility and a smooth surface. The process is particularly suitable for medium-sized series.

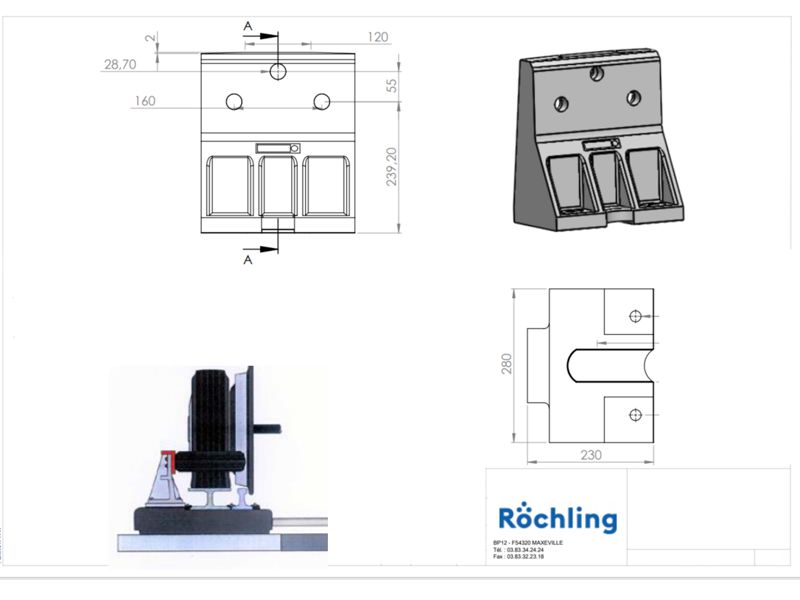

With our presses we are able to produce pressed parts (3-dimensional GRP) with dimensions of 150 x 150 x 150 mm up to 2200 x 1600 x 1200 mm.

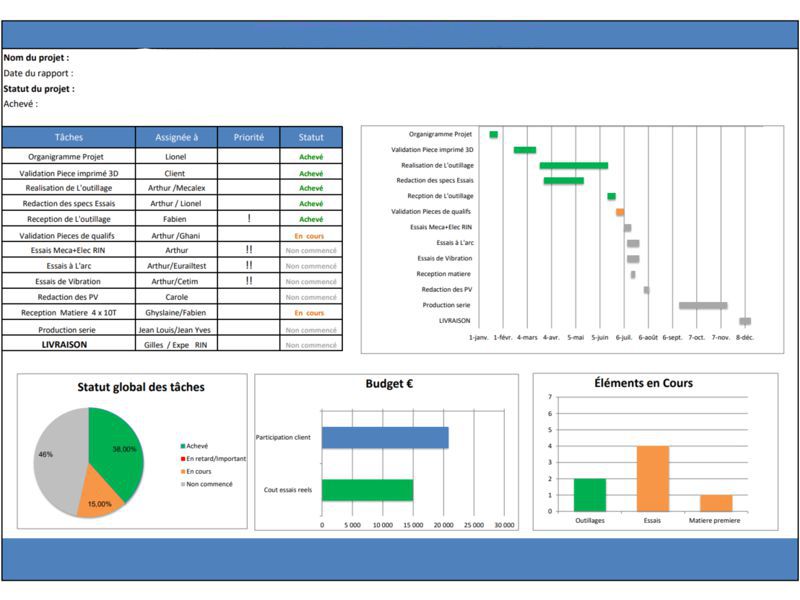

From planning to implementation, our experienced technicians will accompany you throughout the entire project. The result is apart manufactured to your specifications.