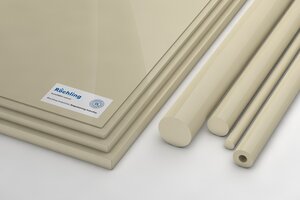

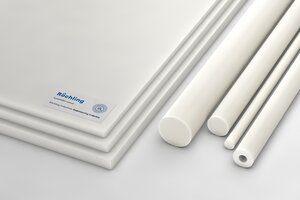

- PEEK (FM4910 resin used)

excellent chemical resistance and low outgassing for components like screws and fasteners - PET

good chemical resistance, strength, stiffness and toughness - PTFE

virtually non-reactive with all chemicals - ECTFE (FM4910 resin used)

typically used where there is exposure to harsh chemicals - PVDF FM4910

typically used where very harsh chemicals are used - PP, PPs

good chemical and acid resistance, UL94-V2, Bright White and Double Annealed - PVC FM4910

fire safe material meet factory mutual standards, typically used for cladding