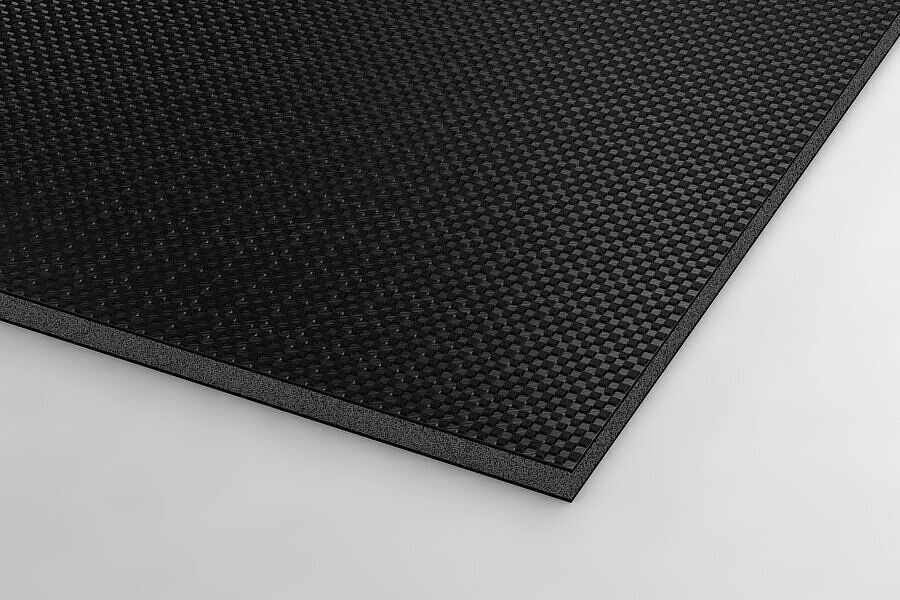

Foamlite® P 653 + UV-stabilized black

PP

Foamlite® – Lightweight plastic sheets for greater benefits

We have developed the closed-pore foamed material Foamlite® especially for applications in which construction materials need to have a very low weight and have a high level of mechanical stability. This opens up a wide range of possibilities in lightweight design.

Foamlite® lightweight boards are nearly 30 per cent lighter than comparable compact sheets. Depending on the application, the lightweight plastic sheet saves on materials, conserves resources and is easy to handle. This gives you

- completely new possibilities in the design of your application and in dimensioning

- as well as economic advantages.

Characteristics

- Low density

- Low moisture absorption

- Anti-slip Surface

- UV-resistant

Röchling impressed us with its Foamlite® material. For us as a manufacturer, this opens up additional perspectives in new markets.

Andreas Jäschke - Managing Director BOX-PROFI the case company GmbH

Variants

Technical Specifications Foamlite® P 653 + UV-stabilized black

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,65 |

| Water absorption | DIN EN ISO 62 | % | 0,1 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | >18 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >1000 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | >20 |

| Shore hardness | DIN EN ISO 868 | scale D | >65 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 162 ... 167 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,15 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,70 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 120 ... 190 |

| Service temperature, long term | Average | °C | -10 … 90 |

| Service temperature, short term (max.) | Average | °C | 150 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 80 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | IEC 60250 | 2,3 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |