SUSTAKON offers new design options

Lahnstein – Röchling is the first plastics processor to offer semi-finished products made of the new, exceptional material polyketone (PK). The characteristics of the plates and rods with the brand name SUSTAKON are unique among polymers. This material opens up brand-new options for engineers for manufacturing parts of plants and machines.

Due to its chemical structure, the polyketone (PK) SUSTAKON offers a unique combination of mechanical, tribological and chemical characteristics. Polyketone combines selected characteristics of different polymers, such as polyamides, polyester, polyacetal and polyolefins. This exceptional profile turns it into a multi-purpose material able to prove its advantages in applications with varying requirements.

Excellent mechanical characteristics

Above all, SUSTAKON is distinguished by its exceptional mechanical characteristics. The resilience of the material is excellent, making it ideal for parts subject to continuous dynamic stress and high load alternation, such as gear wheels or friction bearings.

Its low water absorption rate of 0.4 % in an average climate allows for its use in environments where parts may come in contact with moisture - for instance cable guides used for ship building and off-shore applications. Due to its low water absorption rate, SUSTAKON remains accurate to size and retains its dimensional stability, even after long-term contact with moisture. Its excellent rigidity ensures a long service life.

Exceptional tribological characteristics

Due to its exceptional tribological characteristics, SUSTAKON also opens up new options for planning and designing sliding partners. In general, the wear characteristics of identical friction partners are disadvantageous, meaning that usually different materials have to be coordinated when constructing plants and machines. Compared with other polymers the wear rate of polyketone (PK) is incredibly low when it is used with friction partners made of the same material. If special conditions make it impossible for different friction partners to be used in one application SUSTAKON lets engineers use a single material with first-rate friction and wear characteristics.

First-rate chemical resistance

Its first-rate resistance against aggressive chemicals, lye, lubricants, greases, oils and weak acids allows SUSTAKON to prove its advantages in applications where components are constantly subject to contact with chemicals - for example in seals, pump components, valve flaps or gear wheels in chemical plants and the oil and gas industry.

Development of new parts

Röchling's new material SUSTAKON gives engineers brand-new options for development. The material's special characteristics fulfil the high requirements of various application areas. It allows for components to be used in areas with high mechanical, tribological and chemical requirements at the same time.

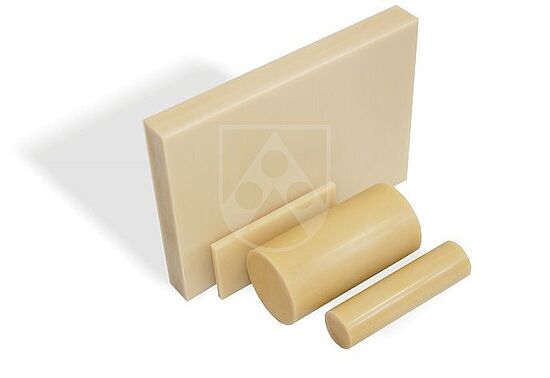

Production range - semi-finished SUSTAKON products

- Round rods: Diameter: 100 mm, length: 3,000 mm

- Sheets: Dimensions: 620 x 3,000 x 50 mm

- Colour: natural

- Other dimensions on request