We have developed the closed-pore foamed material Foamlite® especially for applications in which construction materials need to have a very low weight and have a high level of mechanical stability. This opens up a wide range of possibilities in lightweight design.

Foamlite® lightweight boards are nearly 30 per cent lighter than comparable compact sheets. Depending on the application, the lightweight plastic sheet saves on materials, conserves resources and is easy to handle. This gives you

Properties | Testing method | Unit | Foamlite® |

Density | DIN EN ISO 1183-1 | g/cm³ | 0.65 |

Moisture absorption | DIN EN ISO 62 | % | <0.1 |

E-module | DIN EN ISO 527 | MPa | 1100 |

Shore hardness | DIN EN ISO 868 | Scale D | 70 |

Expanding the portfolio of the Foamlite® lightweight product family with a two-colored sheet. The lightweight plastic sheet is now also available with a different colored core.

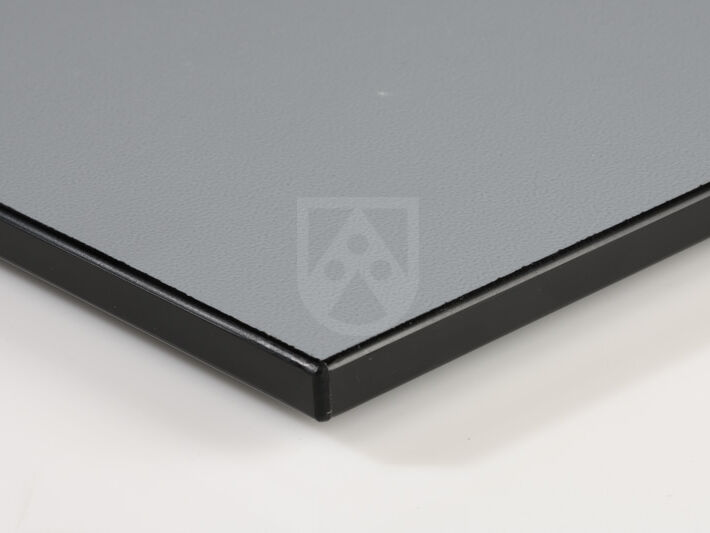

Foamlite® P is a PP-C-based lightweight construction material. With a density of 0.65 g/cm³, Foamlite® P offers clear weight advantages over a sheet made of compact polypropylene at 0.915 g/cm³. The material also has an excellent combination of toughness, high rigidity, strength and chemical resistance. The surface is optionally available with a smooth finish or with a fine grain.

Foamlite® P „cubic grain“

Foamlite® P is available in a slip-resistant design with the special "cubic grain" surface structure. The three-dimensional, cube-shaped grain ensures a mechanical frictional connection between floor and shoe. The slip-resistant property of Foamlite® "cubic grain" is tested according to the following guidelines:

Foamlite® P FG blue

Foamlite® P FG blue is a special material for the food industry. It meets the requirements of EU Regulation 10/2011 – Plastic materials and articles intended to come into contact with food – as well as the requirements of the US Food and Drug Administration (FDA). Its UV resistance makes Foamlite® P FG blue suitable for use in industrial food areas with UV-based hygiene systems. The material is available in blue (RAL 5010). Further colours on request.

Foamlite® P 702 ESD

We have developed Foamlite® P 702 ESD especially for areas where there is a need for controlled conductance of electrostatic charge and low weight at the same time. High voltage pulses can arise with uncontrolled electrostatic discharge and destroy sensitive equipment, components and workpieces. With Foamlite® P 702 ESD , these components are protected by controlled conductance of the electrostatic charge.

Foamlite® G is a PE-HD-based lightweight plastic sheet. With a density of 0.75 g/cm³, Foamlite® G has a weight advantage of more than 20 per cent compared with compact polyethylene at 0.95 g/cm³. The material boasts a superior surface quality, is optionally available with a smooth or grained finish and is very easy to process. At the same time, Foamlite® G can be welded with polyethylene (PE) very easily.

Foamlite® P can be produced in many sizes, thicknesses and colours and with different properties. We are happy to make a product tailored to your individual requirements.

Dimensions:

Colours:

Foamlite® P can be produced in virtually any shade on request.

Many product variants, dimensions and colours are available straight from stock!