We create the industry of tomorrow.

Together with our customers, we develop solutions for increasing efficiency and quality, cost savings and operational reliability - from simple built-in parts to smart controlled serial parts. Because of our experience we can join our strengths, come up with new ideas and thus improve the processes of our partners. Providing our customers with the best solutions is our driving force behind the new product developments.

Where we move

Our innovations

We are always looking to further develop manufacturing techniques and create new solutions in order to keep up with the times. This is how we continuously build our customers‘ confidence with passion and common sense.

Press moulding

Precisely formed components in the highest material quality.

Plastic powder is transformed into three-dimensional plastic products without mechanical processing using heat and pressure. Thanks to unique hybrid technology, pure plastic parts can be reinforced with inserts (e.g. made of steel) to add stability.

Thermoforming

Complex shaping simply implemented.

Thermoforming is a process that shapes ROBALON sheets using heat and vacuum. Two variants are available: one requires only a positive mold and a vacuum foil, often used in prototyping, while the other uses both upper and lower molds made of aluminum or steel for smooth production.

Smart Plastics

Relevant data knowledge with smart plastics

Improve processes and acquire detailed product knowledge, including wear, temperature, and pressure data. As a virtual twin, the system enables early detection of negative influences. This data is sent to the linked IoT platform "Portus" for convenient access to relevant machine data from anywhere.

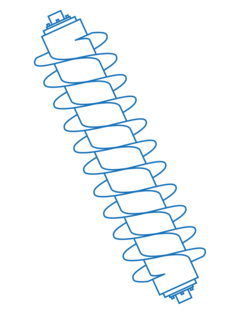

Screw production

Innovative development technology

Robalon screws are chemically resistant, corrosion-resistant, lightweight and have excellent sliding properties. Compared to steel alternatives, they are cost-effective and energy-efficient.

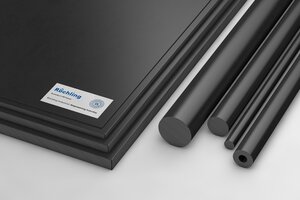

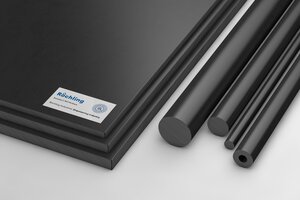

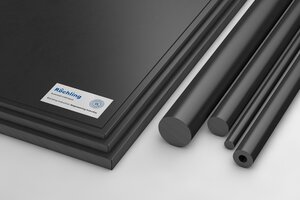

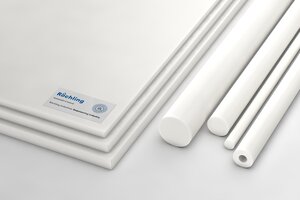

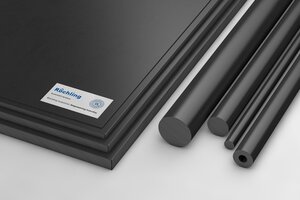

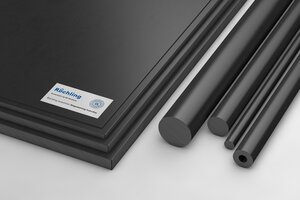

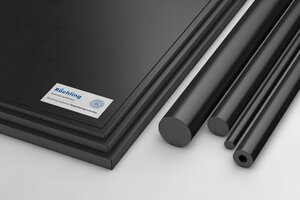

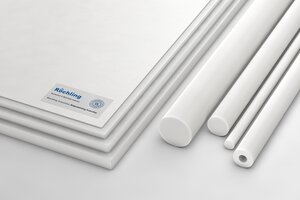

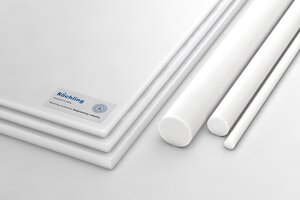

From simple semi-finished products to complex finished parts

We offer tailor-made plastics with properties that often surpass traditional materials such as steel, wood or concrete and are therefore increasingly replacing these materials. There is hardly an industrial product that has not come into contact with, contains or consists of components made of plastic in its manufacturing process. The latest technology as well as modern production machinery allow us to be more broadly positioned concerning machining processes. Our manufacturing includes:

- easy cuts

- custom finished parts

- final execution through assembly services

Modernmachining processes

Milling

Oversized dimensions up to

12 m possible

Turning

Large turned

parts & pipes

Welding

Extrusion welding & Friction welding

Cutting

Panel sizing saws, band saws for round and hollow bars, circular plate saws

Automatic profile mill

no limitation of the processing length, difficult geometries possible, numerous processes combined

More processes

bending and creasing, drilling,

cutting, planing

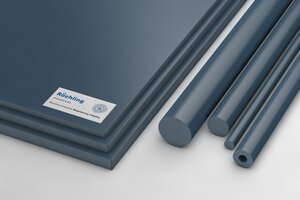

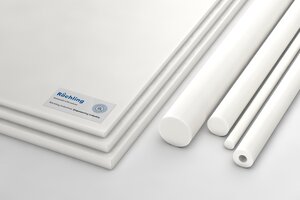

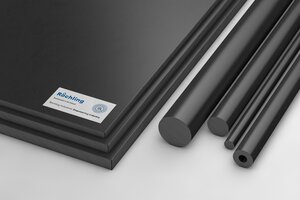

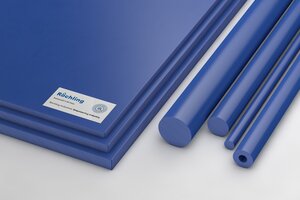

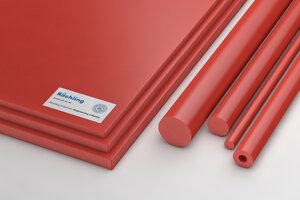

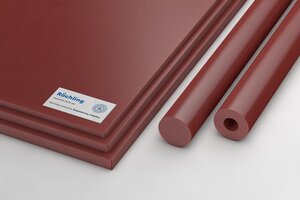

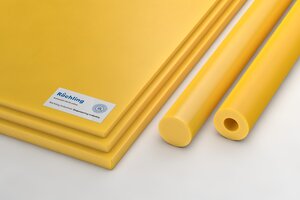

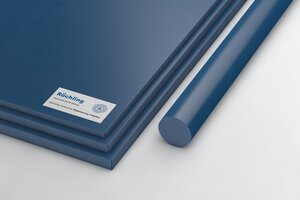

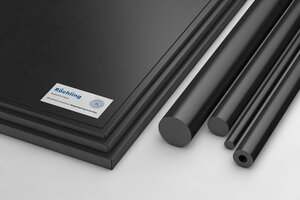

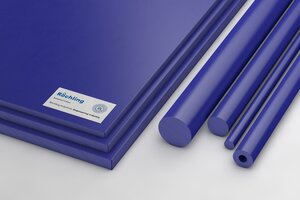

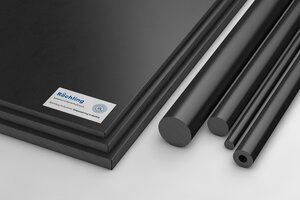

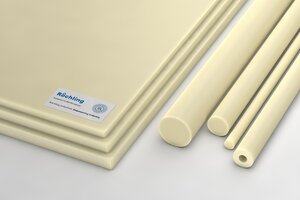

Material competence

at a new level

Our goal is to develop products that are precisly tailored to your applications. Because we know: every industry has its own requirements. At the Oepping site, we have been dealing with the processing and ongoing developments of our main material ROBALON for more than 60 years. Now ROBALON is used in many industries worldwide.

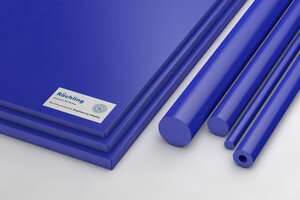

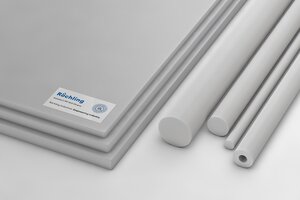

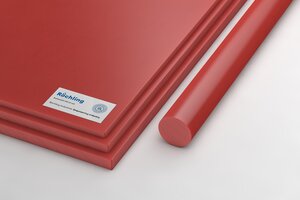

- PE > PE-UHMW - PE 1000

Robalon® E

- PE > PE-UHMW - PE 1000

Robalon® FG

- PE > PE-UHMW - PE 1000

Robalon® S

- PE > PE-UHMW - PE 1000

Robalon® W

- PE > PE-UHMW - PE 1000

Robalon® Z

Why is ROBALON the right choice?

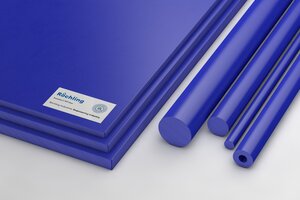

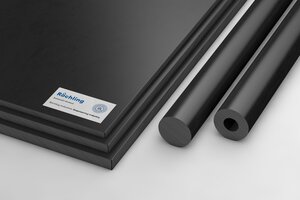

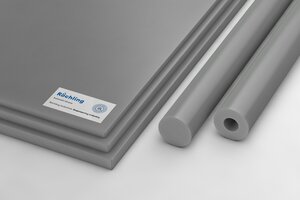

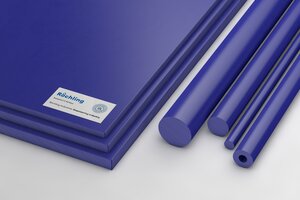

Further standard material

- PA > PA 6 G

Optamid®

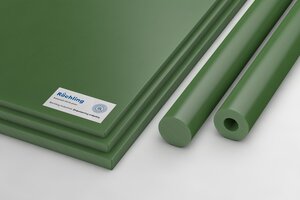

- PA > PA 6 G

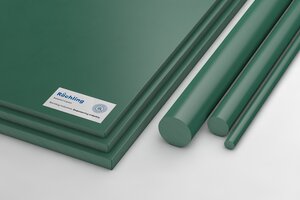

Sustaglide® green

- PA > PA 6 G

Sustaglide® natural

- PA > PA 12

Sustamid® 12 GF 30 natural

- PA > PA 12

Sustamid® 12 natural

- PA > PA 46

Sustamid® 46 brown

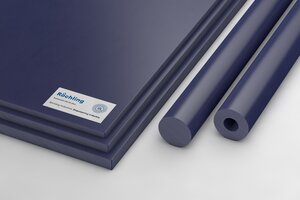

- PA > PA 6

Sustamid® 6 BIO (mb) natural

- PA > PA 6

Sustamid® 6 blue

- PA > PA 6

Sustamid® 6 FG natural

- PA > PA 6

Sustamid® 6 FR black

- PA > PA 6

Sustamid® 6 FR natural

- PA > PA 6

Sustamid® 6 GC black

- PA > PA 6

Sustamid® 6 GC blue

- PA > PA 6

Sustamid® 6 GC natural

- PA > PA 6

Sustamid® 6 GF 30 black

- PA > PA 6

Sustamid® 6 MO black

- PA > PA 6

Sustamid® 6 natural

- PA > PA 6

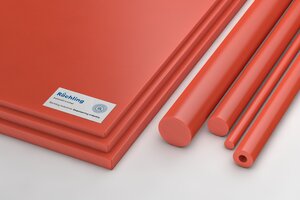

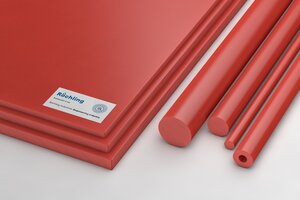

Sustamid® 6 orange

- PA > PA 6

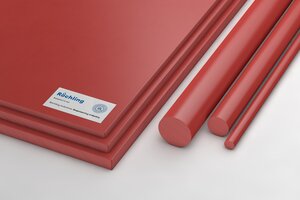

Sustamid® 6 red

- PA > PA 66

Sustamid® 66 black

- PA > PA 66

Sustamid® 66 GF 30 black

- PA > PA 66

Sustamid® 66 MO black

- PA > PA 66

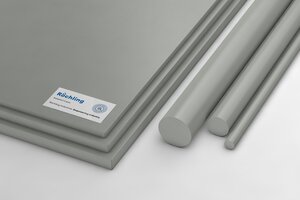

Sustamid® 66 MO grey

- PA > PA 66

Sustamid® 66 natural

- PA > PA 66

Sustamid® 66 red

- PA > PA 6 G

Sustamid® 6G black

- PA > PA 6 G

Sustamid® 6G blue

- PA > PA 6 G

Sustamid® 6G green

- PA > PA 6 G

Sustamid® 6G grey

- PA > PA 6 G

Sustamid® 6G HS black

- PA > PA 6 G

Sustamid® 6G HS blue

- PA > PA 6 G

Sustamid® 6G HS natural

- PA > PA 6 G

Sustamid® 6G LL natural

- PA > PA 6 G

Sustamid® 6G LU red

- PA > PA 6 G

Sustamid® 6G M grey

- PA > PA 6 G

Sustamid® 6G MO black

- PA > PA 6 G

Sustamid® 6G natural

- PA > PA 6 G

Sustamid® 6G OL black

- PA > PA 6 G

Sustamid® 6G OL blue

- PA > PA 6 G

Sustamid® 6G OL green

- PA > PA 6 G

Sustamid® 6G OL grey

- PA > PA 6 G

Sustamid® 6G OL natural

- PA > PA 6 G

Sustamid® 6G OL red

- PA > PA 6 G

Sustamid® 6G OL yellow

- PA > PA 6 G

Sustamid® 6G PD 120 blue

- PA > PA 6 G

Sustamid® 6G PD 140 blue

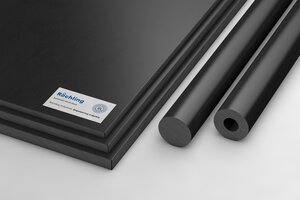

- POM-C

Sustarin® C BIO (mb)

- POM-C

Sustarin® C black

- POM-C

Sustarin® C blue

- POM-C

Sustarin® C brown

- POM-C

Sustarin® C DWS natural

- POM-C

Sustarin® C FG black

- POM-C

Sustarin® C FG blue

- POM-C

Sustarin® C FG natural

- POM-C

Sustarin® C GF 25 black

- POM-C

Sustarin® C GLD 350 blue

- POM-C

Sustarin® C green

- POM-C

Sustarin® C grey

- POM-C

Sustarin® C MDT blue

- POM-C

Sustarin® C natural

- POM-C

Sustarin® C orange

- POM-C

Sustarin® C red

- POM-C

Sustarin® C white

- POM-C

Sustarin® C yellow

- PA > PA 6

Sustavacu® 6 GF black

- PA > PA 12 G

Lamigamid® 1200

- PA > PA 12 G

Lamigamid® 1207/1209

- PA > PA 12 G

Lamigamid® 1209

- PA > PA 12 G

Lamigamid® 1210

- PA > PA 12 G

Lamigamid® 1220

- PA > PA 6 G

Lamigamid® 300

- PA > PA 6 G

Lamigamid® 304

- PA > PA 6 G

Lamigamid® 307

- PA > PA 6 G

Lamigamid® 309

- PA > PA 6 G

Lamigamid® 310

- PA > PA 6 G

Lamigamid® 312

- PA > PA 6 G

Lamigamid® 312 blue

- PA > PA 6 G

Lamigamid® 314

- PA > PA 6 G

Lamigamid® 315

- PA > PA 6 G

Lamigamid® 317

- PA > PA 6 G

Lamigamid® 318

- PA > PA 6 G

Lamigamid® 319

- PA > PA 6 G

Lamigamid® 320

- PA > PA 6 G

Lamigamid® 324/327

- PA > PA 6 G

Lamigamid® 339

- PA > PA 6 G

Lamigamid® 400B

- PA > PA 6 G

Lamigamid® 450N

- POM-C

Sustarin® C PIR black

Your contact persons

Thomas Meisinger

T: +43 7289 4611-238

M: TMeisinger@roechling.com

Industries

- Agriculture

Georg Zoitl

T: +43 7289 4611-235

M: GZoitl@roechling.com

Industries

- Alpine

- Materialhandling & Elevator

Daniel Michaeler

T: +43 664 8451 756

M: DMichaeler@roechling.com

Industries

- Transportation

Roland Gabriel

T: +43 7289 4611-297

M: RGabriel@roechling.com

Industries

- Environmental & Renewable

- Mechanical Engineering

AT: OÖ, SBG, T, VBG

DE: PLZ 5, 6, 7, 8, 9

You want more information?

Get more details in our downloads section.