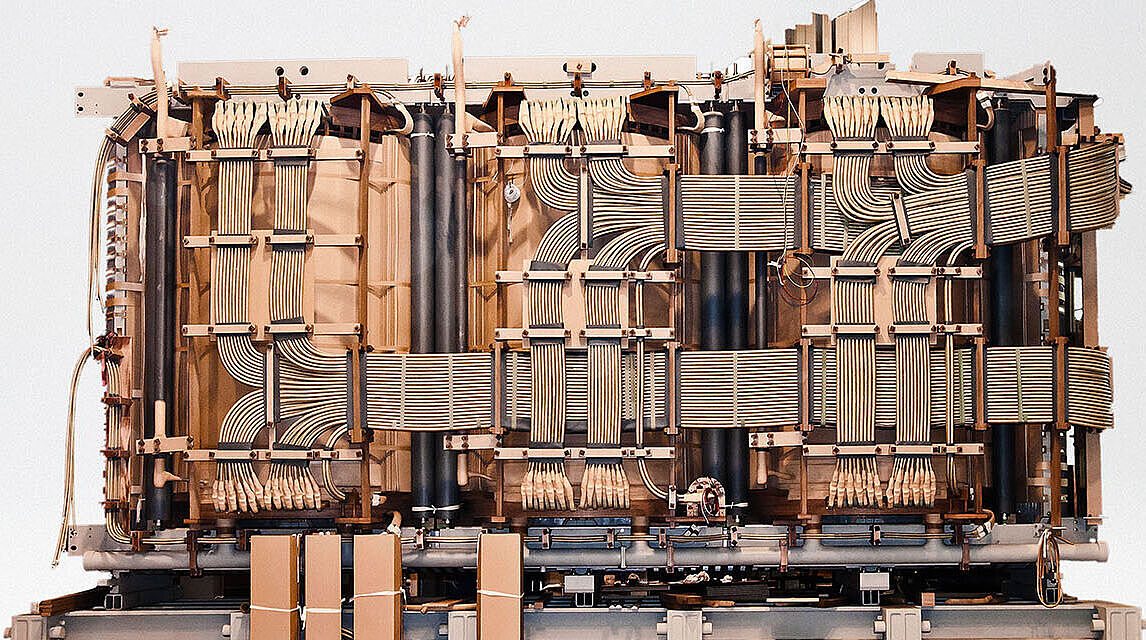

Lignostone® - Laminated densified wood

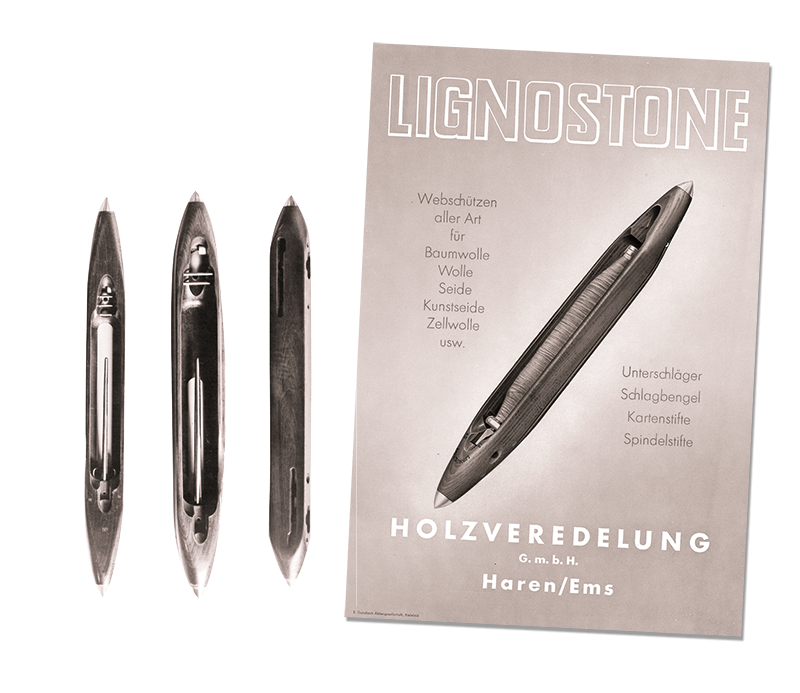

Buy from the inventor and global market leader of laminated densified wood - more than 100 years of experience

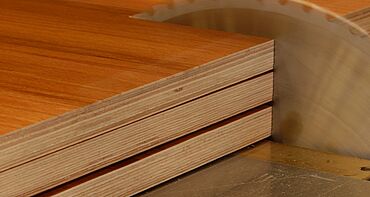

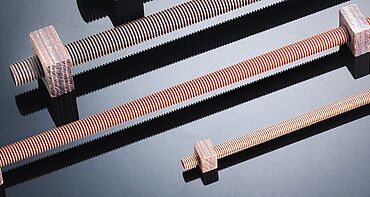

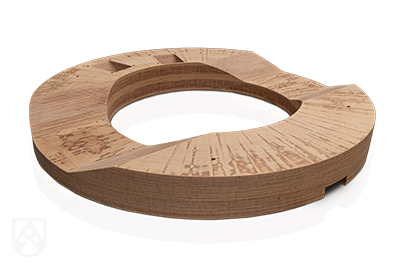

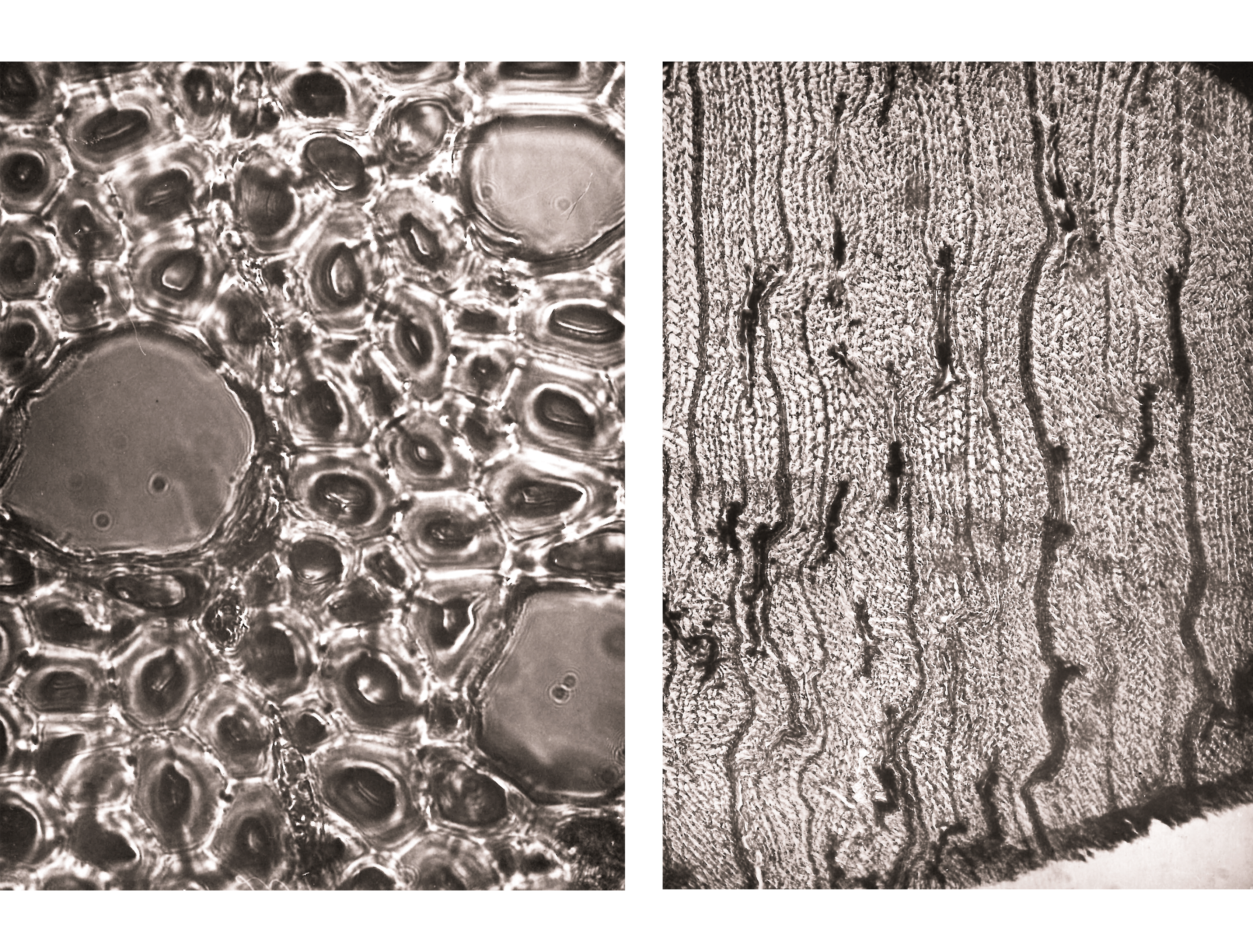

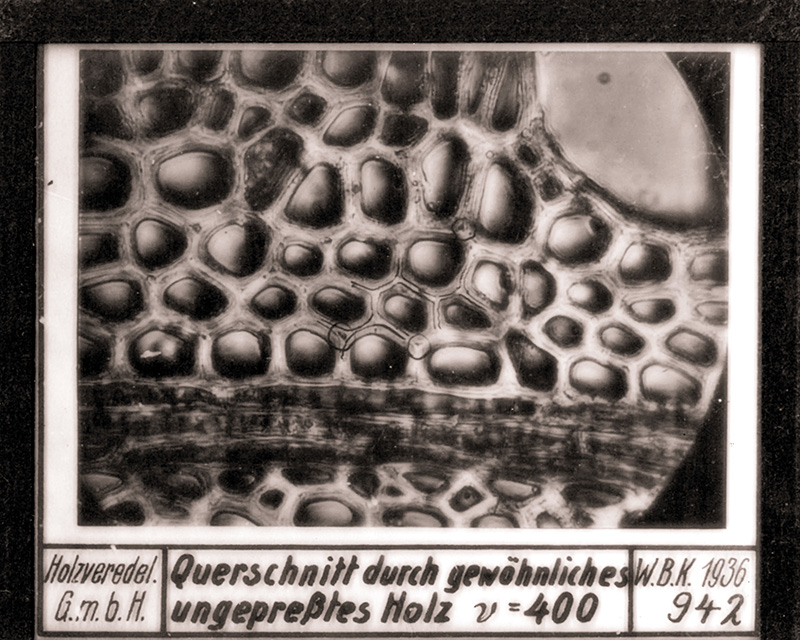

Lignostone® - laminated densified wood directly from the inventor. Consisting of veneers of the common beech (Fagus sylvatica) bonded using curable synthetic resins in conjunction with pressure and heat. More than 100 years of experience. For exceptional and scientifically proven mechanical and isolating properties.