High thermal insulation

As fibre-reinforced plastics, Durostone® and Glastherm® have a very low coefficient of thermal conductivity of 0.18–0.3 W/mK compared to that of conventional construction materials such as steel (15–58 W/mK). Thus, the thermal properties of materials are comparable to mineral wool, which is used as an insulation material in construction.

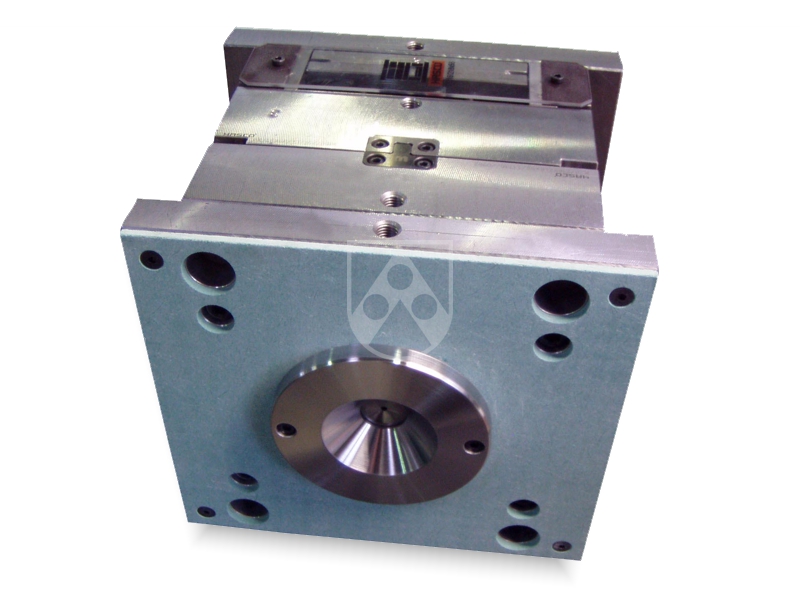

Avoid thermal bridges and cold bridges

With their high thermal insulation, Glastherm® and Durostone® contribute specifically to the avoidance of thermal bridges and cold bridges in your application. Depending on the area, they support a uniform process, the application or ambient temperature, and prevent energy losses.