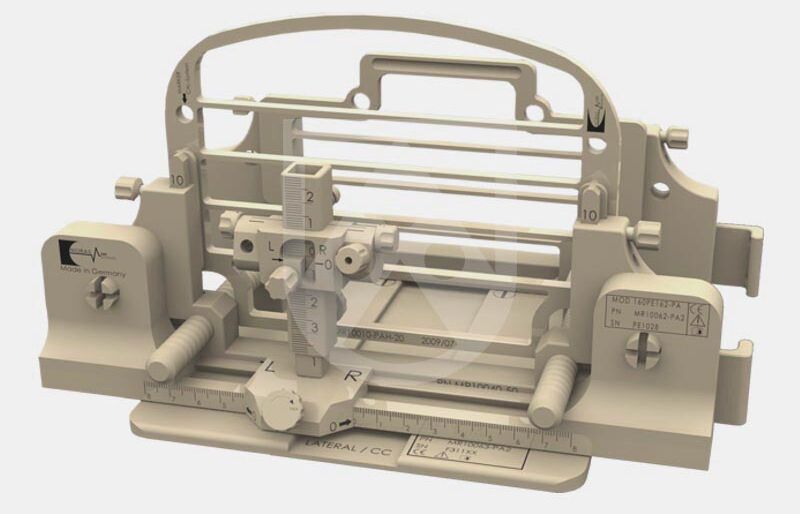

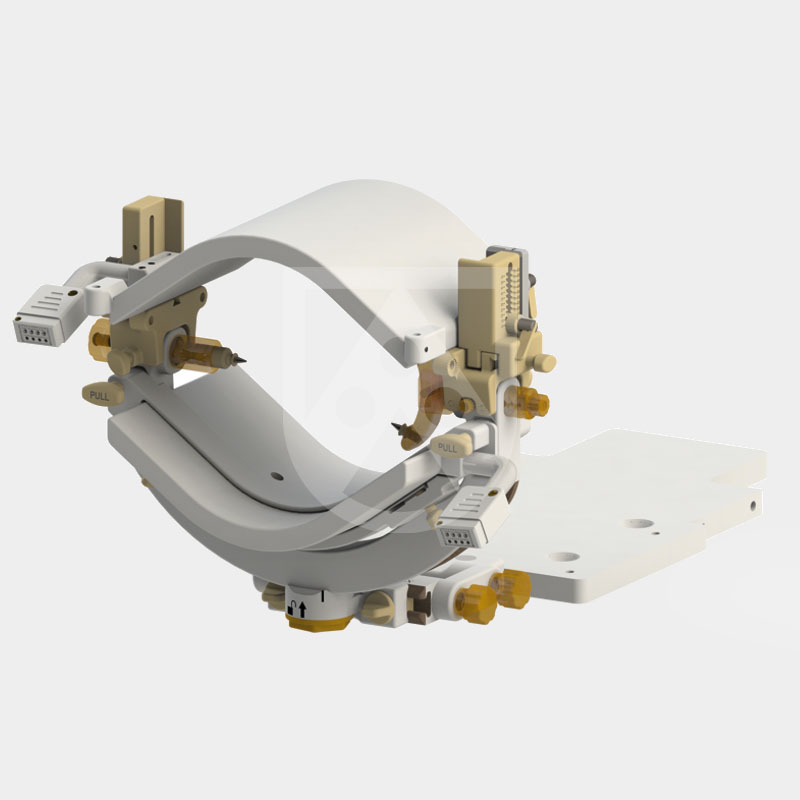

Precision plastic parts / precision machined components

Precision turned parts and milled parts made of plastic

We manufacture high-precision CNC turned and milled components made of thermoplastic materials. Machined in accordance with our clients’ specifications.

- Prototypes, small series or large series

- Having very tight tolerances, thin wall thicknesses and an excellent surface quality.