Lignostone® cryogenic

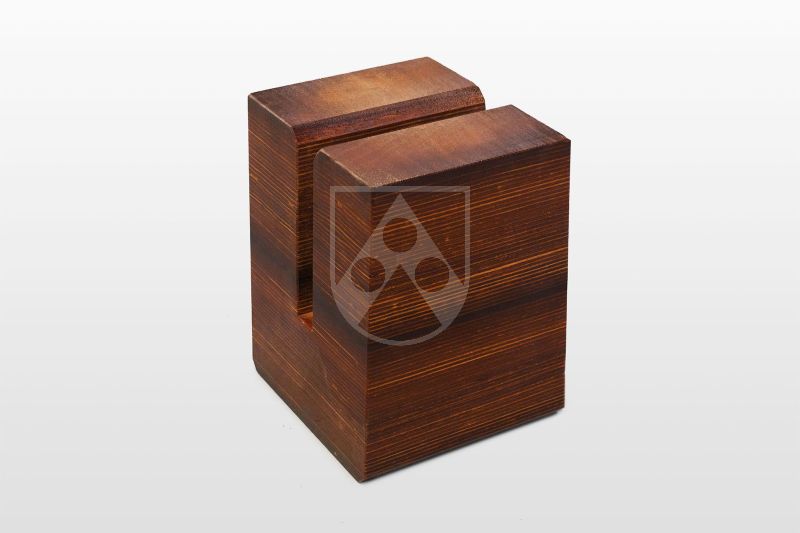

The material Lignostone® cryogenic consists of laminated densified wood impregnated with synthetic resin, manufactured from a renewable material, selected beech veneers (Fagus sylvatica). It is impregnated under vacuum with thermosetting synthetic resin and densified under heat and pressure. This produces a unique character profile that makes it ideal for thermal insulation of LNG systems.

Proven applications include:

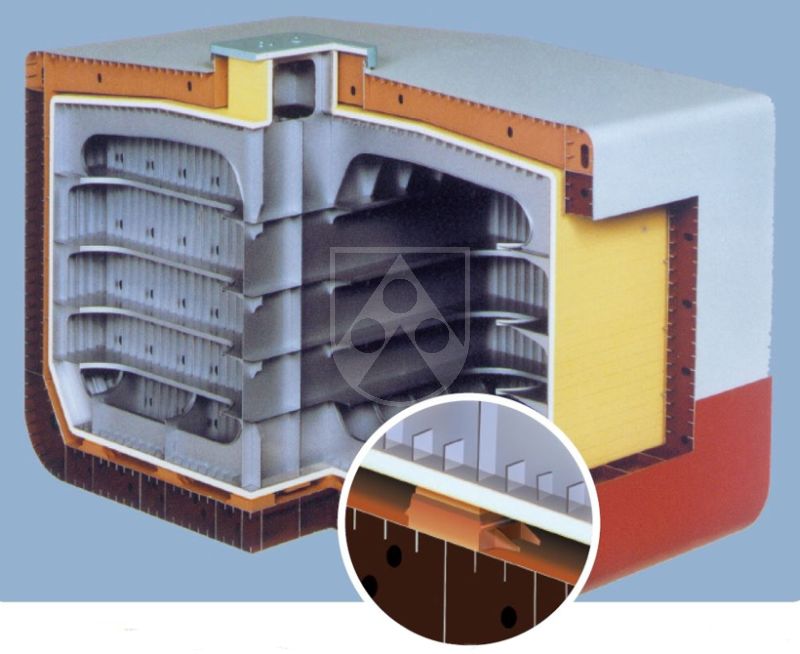

- Tank insulation for carriers: Lignostone® cryogenic has been used for decades throughout the world for tank supports in LNG, LPG and ethylene tankers. This material is used for insulating large storage tanks with dimensions of up to 165,000 m³ from the tanker structure, and has been approved by many renowned companies. More information about Lignostone® cryogenic LNG and LPG cryogenic tank insulation

- LNG fuel tanks for LNG engines: Lignostone® cryogenic is used for the insulation of LNG fuel tanks of ships, and thus contributes towards the reliability and durability of modern and environmentally friendly LNG drives. More information about Lignostone® cryogenic for LNG fuel tanks

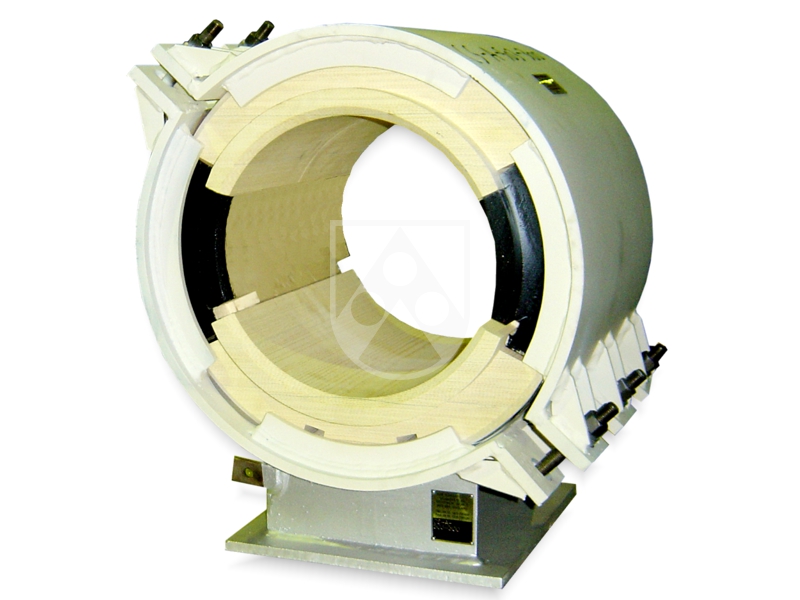

- Pipe supports

Properties - Lignostone® cryogenic:

- Low thermal conductivity

- Outstanding temperature resistance: -196 °C to +90 °C

- High mechanical strength

- Low coefficient of slide friction

- High wear and abrasion resistance

- Low specific weight

Advantages:

Lignostone® cryogenic

- reliably insulates LNG storage tanks, fuel tanks and pipe systems

- and thus, contributes towards the efficiency, durability and reliability of these applications.