SustaPEEK - ASTM

PEEK

Characteristics

- Flame retardant

- Self-extinguishing

- Low smoke density

- Good dimensional stability

Industries

- Semiconductor Wafer Handling

- Semiconductor Front-End Wet Bench

- Semiconductor CMP

- Semiconductor High and low temperature

- Semiconductor Back-End applications

- Semiconductor factory equipment

- Semiconductor Dicing

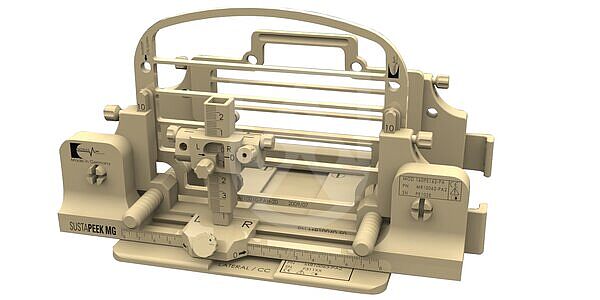

Application Examples

Technical Specifications SustaPEEK - ASTM

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | ASTM D792 | g / cm3 | 1.32 |

| Water Absorption 24 hours | ASTM D570 | % | 0.1 |

| Dissipation Factor | ASTM D150 | 1MHz | 0.003 |

| Water Absorption Saturation | ASTM D570 | % | 0.5 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hardness | ASTM D2240 | Shore D | 85 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 16000 |

| Tensile Modulus | ASTM D638 | psi | 500000 |

| Elongation at Break | ASTM D638 | % | 20 |

| Flexural Strength | ASTM D790 | psi | 25000 |

| Flexural Modulus | ASTM D790 | psi | 600000 |

| Compressive Strength | ASTM D695 | psi | 18000 |

| Rockwell Hardness | ASTM D785 | 105 | |

| Rockwell Hardness | ASTM D785 | R | 126 |

| Shear Strength | ASTM D732 | psi | 7700 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | 1.2 |

| Coefficient of Friction, Dynamic | 0.4 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Thermal Conductivity | in/hr/ft2 /°F | 1.73 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | in/in/°F x10-5 | 2.6 |

| Melting Point | ASTM D789 | °F | 630 |

| Continuous Service Temperature, Air | °F | 480 | |

| Deflection Temperature at 1.8Mpa (264psi) | ASTM D648 | °F | 320 |

| Deflection Temperature at 1.8Mpa (66psi) | ASTM D648 | °F | 360 |

| Flammability, UL94 | 1/8 inch | V-0 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | ASTM D150 | 1MHz | 3.3 |

| Dielectric strength | ASTM D149 | V/mil | 480 |

| Surface resistivity | ASTM D257 | Ω/cm | 1013 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| FDA | Yes | ||

| NSF | No | ||

| USDA | Yes |