ROBASEAL sealing strips

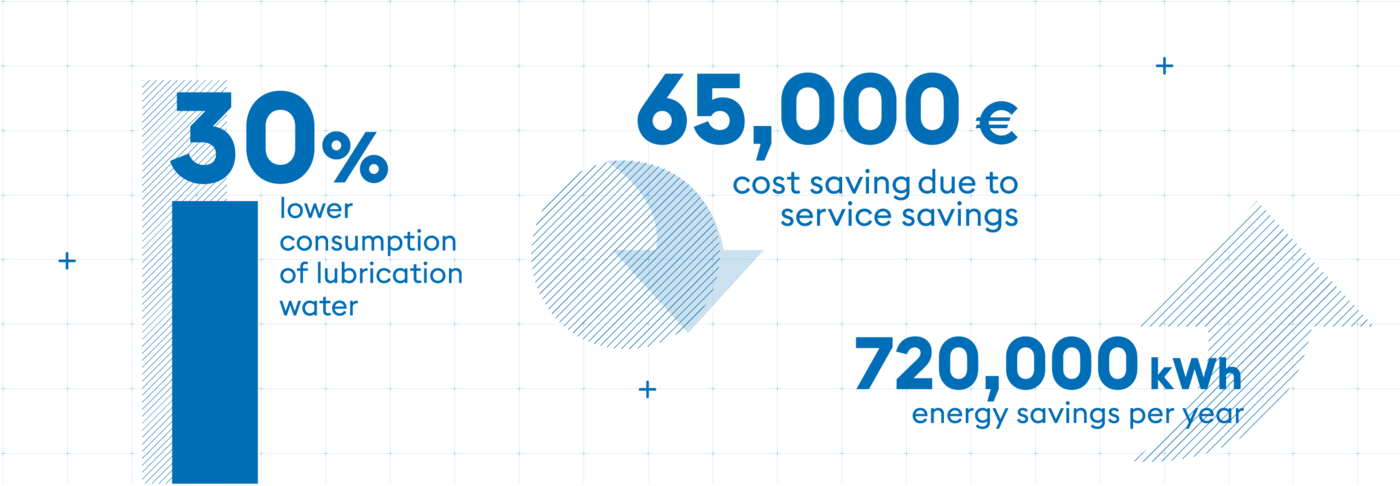

RobaSeal sealing strips enable you to optimize the operation of your suction roll in the long term. Thanks to innovative material properties and perfectly coordinated lubrication systems, running times can be extended, maintenance costs reduced, and energy consumption significantly lowered.

Greater efficiency, lower resource consumption.

Why to choose RobaSeal sealing strips?

What makes RobaSeal so special:

Highest operational safety

The operational safety of a paper machine depends on the suction rolls functioning consistently. This in turn is affected by the correctly specified, coordinated sealing strip systems, adjustment and lubrication water systems in the suction rolls.

Avoiding unplanned shutdowns

Correctly coordinated sealing strip systems ensure that unplanned shutdowns are avoided, which means savings of up to 250,000 EUR.

Outstanding energy balance

RobaSeal sealing strip systems significantly reduce the frictional power. This leads to much lower wear and reduces the friction performance.

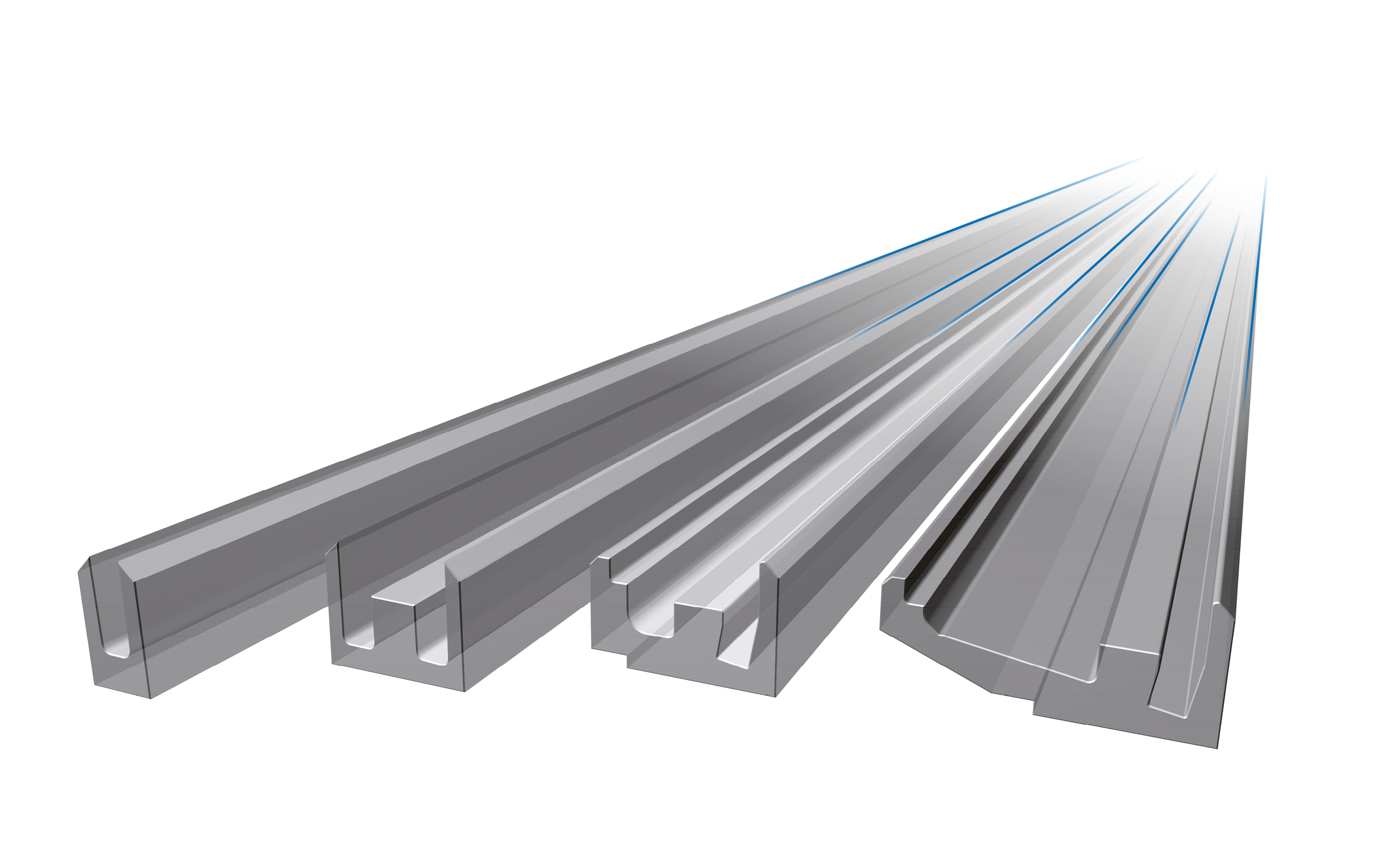

Sealing strips and end deckles

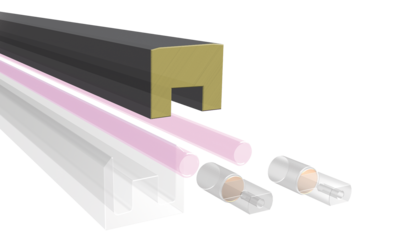

ROBASEAL®-A

High-performance polymer based on rubber graphite

_ Long service life, low wear, high thermal resistance

_ Low coefficient of friction = lower energy consumption

= high efficiency

_ Very good emergency running properties

DEPLOYMENT LOCATION:

For all sealing strips and end deckles at all machine speeds

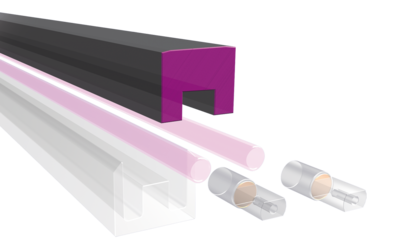

ROBASEAL®-S

Compounded with lubricating additives for additional service life and even lower coefficient of friction

_ Reduced lubrication water requirement

_ Low coefficient of friction = lower energy consumption

= highest efficiency

_ For lengthening service cycles

DEPLOYMENT LOCATION:

Wherever efficiency and durability are a priority

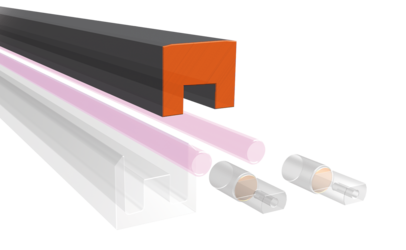

ROBASEAL®-F

Rubber graphite material, extruded and vulcanized

_ Short run-in time

_ Shutterproof

_ High thermal stability

_ Good emergency running properties

DEPLOYMENT LOCATION:

For all sealing strips and end deckles at all machine speeds

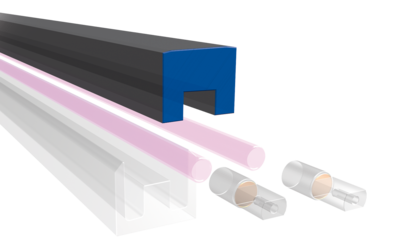

ROBASEAL®-L

Thermoplastically bound rubber graphite

_ Energy savings – lower coefficient of friction compared

to unfilled thermoplastics

_ Better emergency running properties thanks to integrated graphite

_ Break-proof and flexible sealing strip

DEPLOYMENT LOCATION:

Sealing strips and end deckles up to 800 m/min machine speed

Sealing strip holder

ROBAGUIDE sealing strip holder

Sealing strip holders made of glass fiber reinforced plastic offer unbeatable value for money and unrivaled quality.

_ Protects the roll cover in the event of bearing damage

_ High chemical and hydrolysis resistance

_ Low weight with high mechanical strength and rigidity

_ Available for almost all suction rolls

DEPLOYMENT LOCATION:

In all suction rolls with RobaSeal sealing strips

Sealing strips for noise reduction and energy saving

ROBASEAL®-A/-S/-L/-F

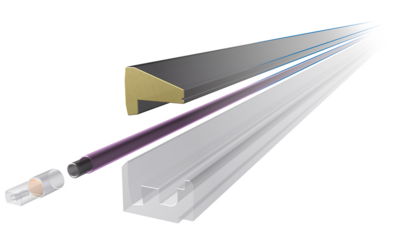

SeaLencer (patented)

Significant reduction in noise emissions. The patented design enables a drastic reduction in noise emissions. The minimal friction surface also significantly reduces drive power.

_ Significant reduction in noise emissions by at least 3 dBA

_ 90% smaller friction surface

_ Significant reduction in friction power

_ Available in quality grades -A/-L/-S/-F

ROBASEAL®-A/-S/-L/-F

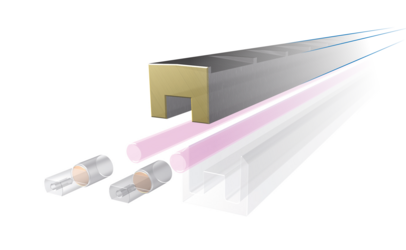

Energy Saver Light

The simple design allows standard sealing strips to be replaced with Energy Saver sealing strips. This reduces noise emissions and drive power for almost all rolls.

_ Reduced friction

_ Reduction in noise emissions

_ 80 % smaller friction surface

_ Easy replacement without modification

_ Available in quality grades -A/-L/-S/-F

Sealing strip loading tubes

ROBATUBE-T

The RobaTube-T is characterized by excellent stroke characteristics at low operating pressure and maximum reliability. Its good chemical and thermal resistance allows it to be used in a wide range of suction rolls.

_ Temperature resistant up to 70° C

_ Chemically resistant

_ Large stroke at low pressure

DEPLOYMENT LOCATION:

_ In all suction rolls of the paper machine

ROBATUBE-ES

The two-layer structure maximizes the advantages. Maximum chemical and thermal resistance, high mechanical strength, and outstanding stroke behavior guarantee reliable use in all suction rolls.

_ High thermal resistance up to 120°C

_ High chemical resistance

_ Outstanding lifting behavior

DEPLOYMENT LOCATION:

_ In all suction rolls of the paper machine

Discover more of our solutions in the paper industry

Browse through our reference catalog and learn how our products are used in paper machines worldwide.

Be inspired by best practice examples and innovative applications.