We process the high performance plastic PEEK (Polyetheretherketone) under the brand name SustaPEEK as semi-finished products in the form of sheets, rods and tubes as well as machined components.

PEEK (Polyetheretherketone) is a semi-crystalline, thermoplastic high-performance material, and is characterized mainly by its very good mechanical properties and exceptional dimensional stability, even at high continuous operating temperatures of up to 250°C. PEEK plastics are suitable for a wide range of applications with demanding operating conditions.

Product range – SustaPEEK:

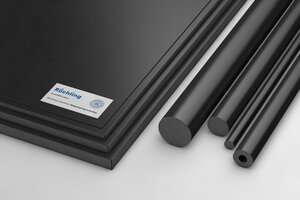

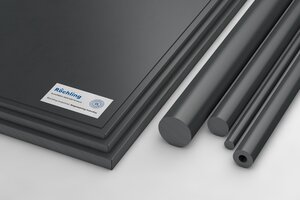

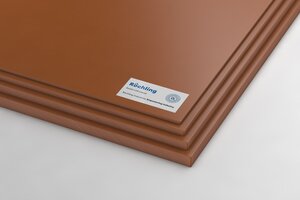

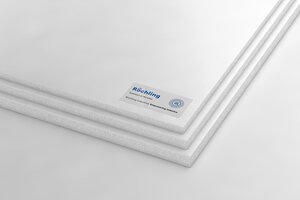

SustaPEEK is available as a semi-finished product in numerous dimensions and colors:

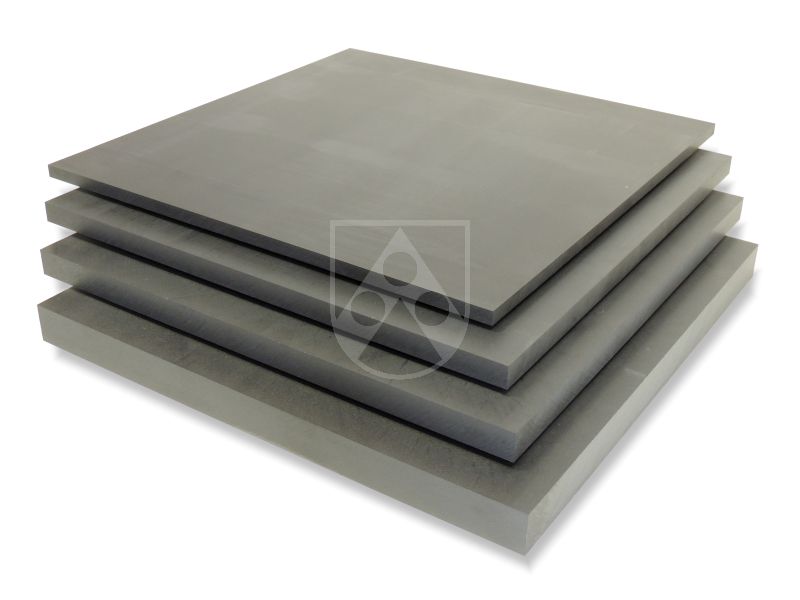

- PEEK sheets

- PEEK round rods

- PEEK tubes / tubing

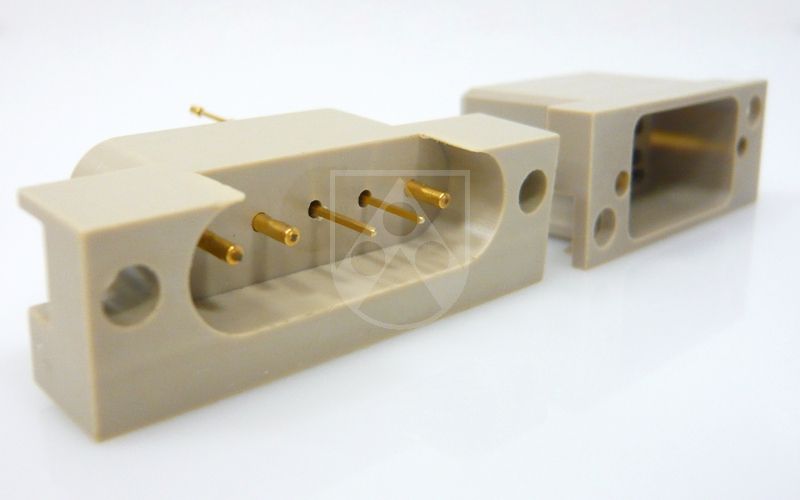

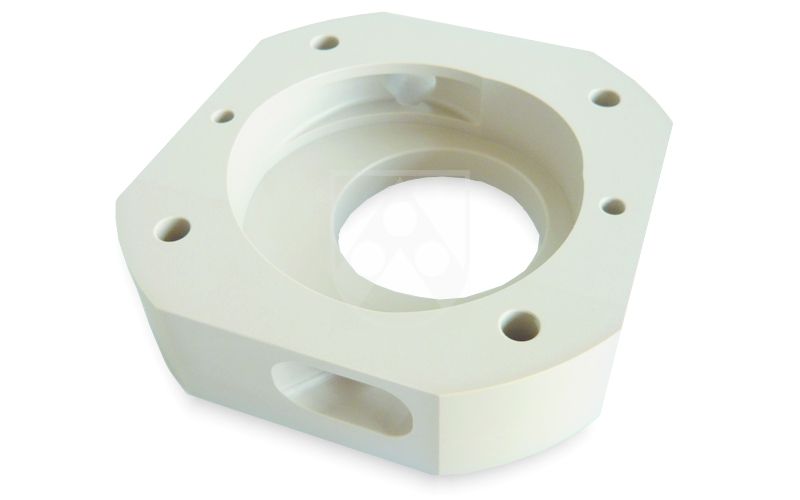

We also offer PEEK machined components on the basis of customer drawings.