Focus on small-scale production of complicated components

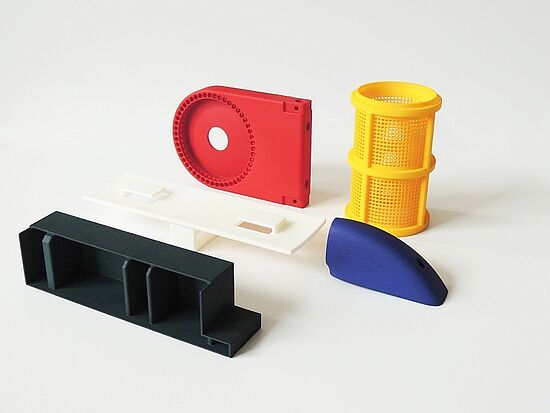

Lützen – Investing in a SLS (selective laser sintering) plant, Röchling Technische Kunststoffe KG, Lützen, has been offering the possibility of manufacturing the most complex machined components in a 3D printing method since October this year. Here, Röchling is focussing on small-scale production of components which could not be realised with the technologies available hitherto. For customers, this process opens up new options in the development of innovative components.

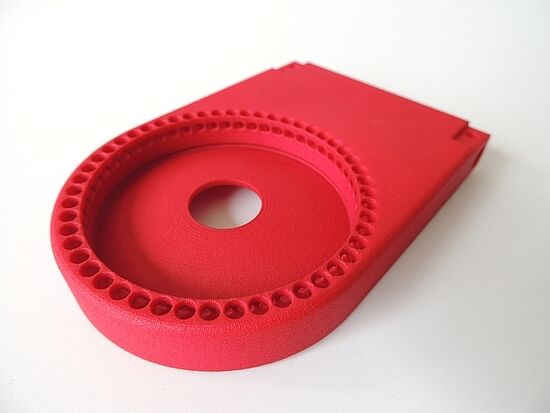

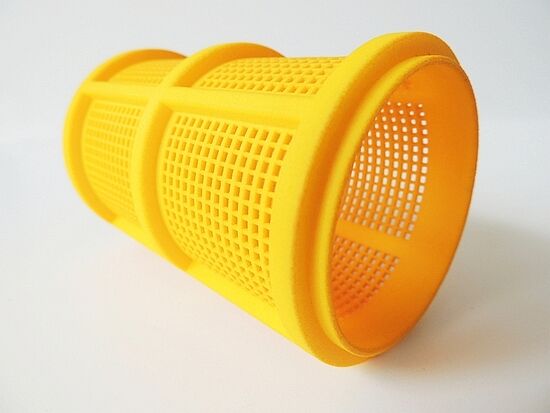

Klaus Trittmacher, Managing Director of Röchling Technische Kunststoffe KG, Lützen, location of the Centre of Excellence for 3D printing within the Röchling Group, says to the launch: “As leader of technology in plastics processing, we are permanently concerned with new technologies, such as the additive layering construction method. With selective laser sintering, we offer, after successful trial runs, an innovative technology for the production of the most complicated components and have extended our comprehensive range of cutting-edge processing techniques.” Selective laser sintering facilitates production of the most complicated three-dimensional components which could not be realised with the technologies available hitherto, such as, by way of example, CNC machining or injection moulding.

With this technique, spatial structures made of powdered plastic using laser beams can be manufactured through sintering in one processing step. Compared to other 3D printing processes, SLS has distinct benefits with regard to the quality and mechanical strength of the components as well as the reproducibility.

Rapid manufacturing – the focus on small-scale production

Röchling focuses first and foremost on the production of short runs of complex components that can be realised in a relatively short period – also called rapid manufacturing. What is more, Röchling offers production of prototypes which make components never manufactured to date easy to grasp in the true sense of the word. This enables adaptations to the design or functional tests to be performed relatively inexpensively. “Initial talks with customers have indicated very great interest in the new production process that offers completely new constructive options,” says Trittmacher.

Development of new components

With long-standing experience in technical design and construction of components for numerous branches, Röchling possesses excellent expertise in the implementation of plastic in technical applications. “We see our mission in advising our customers in developing new, innovative components. If desired, we will undertake the complete construction of the components in accordance with the customer’s terms of reference,” Trittmacher highlights the intensive cooperation with the customer in developing and manufacturing new components.

With this investment, the High-Performance Plastics division of the Röchling Group, which Röchling Technische Kunststoffe KG belongs to, extends their extensive know-how in the processing of high-performance plastics to make semi-finished products and machined components that are used in numerous applications in the capital goods industry.

At the K 2013 in Düsseldorf from 16. to 23.10.2013, Röchling presented examples of components manufactured in 3D printing (Hall 8a/J12)