LubX®: Advanced Sliding Materials for Optimal Conveyor System Performance

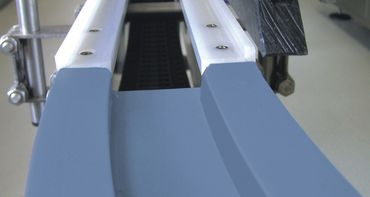

Conveyor systems across diverse industries encounter a wide range of loads and environmental conditions, which significantly impact the friction and wear performance of materials. In 2012, Roechling's introduction of LubX® revolutionized the field of sliding materials by being the first to consider the real-world interaction between sliding partners during material development.

LubX® C and LubX® CV are carefully engineered sliding plastics, each designed to deliver outstanding friction-reducing properties for specific sliding systems and environmental conditions. To achieve this, we conducted extensive tribological testing under various conditions and verified our results in collaboration with leading plastics and conveyor technology labs after rigorous in-house testing.

LubX CV+ | New material solution for high-speed systems

With LubX® CV+, Röchling Industrial is expanding the proven LubX® product family with a solution specially optimised for high-speed systems. The further developed material properties ensure further reduced friction, improve energy efficiency and reduce maintenance and servicing costs - ideal for modern intralogistics processes with high speeds.

Comparative tests with other materials show that LubX® CV + impresses with significantly optimised sliding properties and sets new standards for high-performance applications in conveyor and automation technology.

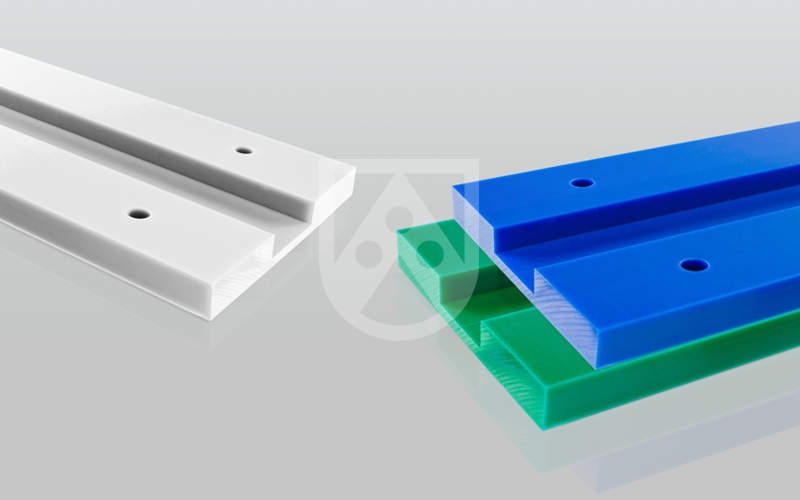

Overview of LubX® sliding materials

| Antistatic | Noise reduction | Food-safe | Products | |||||

| FDA | EU 10/2011 | Rod | Sheet | Profile | Machined Part | |||

| LubX® CV+ | ● | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| LubX® CV | ○ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| LubX® CV AST color | ✓ | ○ | ✓ | ✓ | ✓ | ✓* | ✓ | |

| LubX® C | ○ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| LubX® CQ | ● | ✓ | ✓ | ✓ | ✓ | |||

| LubX® S | ○ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| LubX® AST black | ✓ | ○ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| LubX® AST color | ✓ | ○ | ✓ | ✓ | ✓ | ✓ | ✓* | ✓ |

✓= available

● = Major improvement (compared to a standard PE-UHMW)

○ = Improvement (compared to a standard PE-UHMW)

*only available on request

Material Selection

Our sliding materials have been used in conveyor systems all over the world for decades. What we know: Every system has different requirements for the sliding materials used. The information in the table is an initial guide, but on no account can itreplace expert advice on selecting the right sliding material for your conveyor system.

Key factors

The performance and service life of sliding materials for conveyor systems is determined by various influencing factors. These have to be taken into account for the selection. For instance:

- Mating surfaces

- Mechanical load

- Design requirements

- Dimensions and tolerances

Contact us

We would be happy to assist you in selecting the best sliding material for your application. Just use our contact form at the bottom of the page and drop us a note.

Why is it so important to consult us regarding the proper choice of sliding material?

There is no typical material characteristic value for the friction and wear of a material. The selection is about the "system properties", i.e. the analysis of further influencing variables and parameters from the individual application. The tribological system (Tribosystem for short) was introduced for this purpose. In addition to the two friction partners, it also comprises further influencing variables such as the intermediate material, the ambient medium and the ambient conditions present, such as the movement sequence, the length of time, the pressure and the temperature in addition to the conveying velocity and the layout of the conveyor system. A suitable sliding material for an application can only be selected if all parameters have been systematically considered. (See: Czichos, Habig (2015), p. 14, Tribology Manual, 4th Edition, Springer-Verlag, Wiesbaden)

Tribological measuring system

A tribological system describes the interactions between moving surfaces that are in contact with each other. It typically consists of three main components: the base body, the mating body and the intermediate material (e.g. lubricant). The tribological properties of a system - friction, wear and lubrication - have a significant influence on the efficiency and service life of mechanical components. Through the targeted use of special materials, such as our high-performance plastics with optimised sliding properties, friction losses can be reduced, wear minimised and the performance of machines and systems increased.

LubX® CV+

With LubX CV+ we are expanding the proven LubX® product family with a solution specially optimised for high-speed systems. The further developed material properties ensure further reduced friction, improve energy efficiency and reduce maintenance and serving costs - ideal for modern intralogistics processes with high speeds.

- LubX CV+

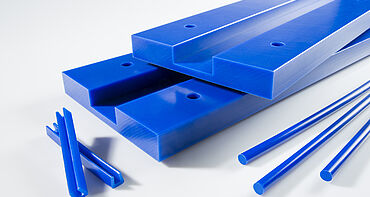

LubX® CV

Sliding material developed particularly for systems that are to be operated at higher speeds and compressive loads and thus higher productivity.

LubX® CV AST color

Permanently anti-static sliding material, coloured and having excellent sliding properties. Particularly suitable for conveyor systems that are to be operated at higher speeds and where an anti-static effect is required.

LubX® C

High-performance sliding material, specifically adapted to POM and steel and having outstanding dry-running properties.

LubX® CQ

Sliding material developed particularly for systems that are to be operated at higher speeds and compressive loads and thus higher productivity.。

LubX® S

High-performance sliding material, especially adapted to a mating surface made of PET, having outstanding dry running properties.

- LubX® S compr.

- LubX® S extr.

LubX® AST black

Anti-static sliding material that combines excellent tribological properties with controlled electrostatic discharge. Especially for systems in materials handling that are to be operated at high speeds.

LubX® AST color

Anti-static sliding material coloured, for the design of economical and safe conveyor systems for transporting sensitive goods.

Do you have questions about choosing the right material?

We will be happy to advise you on the selection of the right sliding materials for your application. Simply use our contact form at the bottom of the page and write to us.